Manufacturing method of mo alloy sputtering target and mo alloy sputtering target

A technology of sputtering target material and manufacturing method, which is applied in the manufacture of Mo alloy sputtering target material and the field of Mo alloy sputtering target material, can solve the problems of low adhesion of substrates, achieve excellent adhesion and improve reliability , the effect of low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

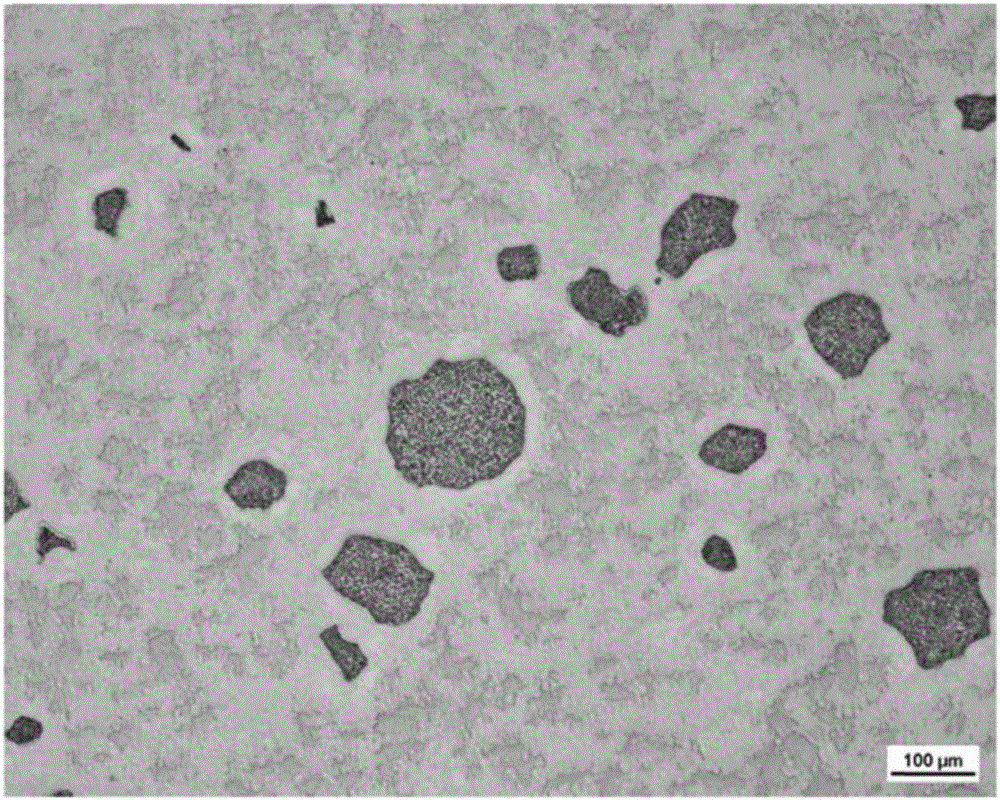

[0055] In order to produce a Mo alloy sputtering target material consisting of 20%Ni-15%Ti in atomic ratio-the remainder is composed of Mo and unavoidable impurities, the following powders are prepared: Mo powder with a purity of 99.99% and an average particle size of 6μm; Ni-30 atomic % Mo alloy powder with a purity of 99.9% and an average particle size of 70 μm produced by the chemical method; Ti powder with a purity of 99.8% and an average particle size of 30 μm.

[0056] Each powder was weighed so that it might become a component of the said Mo alloy sputtering target material, and it mixed using the cross rotation mixer, and the mixed powder was obtained. After that, it was filled into a mild steel container with an inner diameter of 133 mm, a height of 30 mm, and a thickness of 3 mm, and was degassed by heating at 450° C. for 10 hours. Then, the mild steel container was sealed and kept at 1000° C. and 148 MPa for 5 hours for sintering. After cooling, it was taken out fr...

Embodiment 2

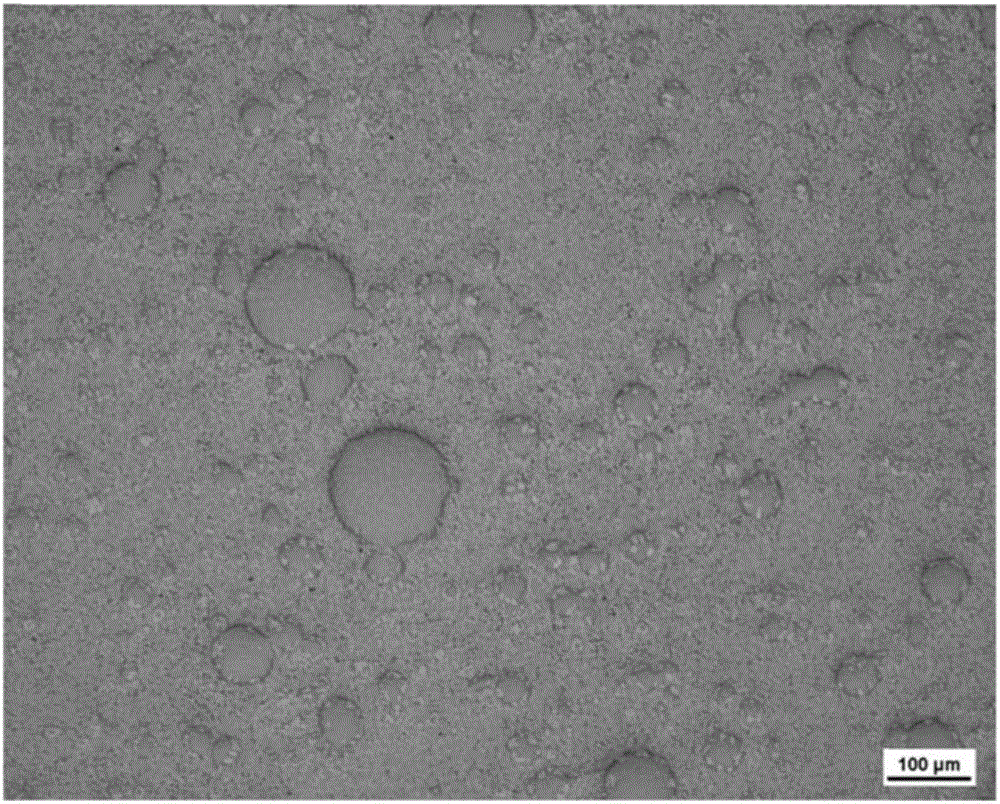

[0067] In order to make a Mo alloy sputtering target with atomic ratio of 15%Ni-15%Ti-the rest is composed of Mo and unavoidable impurities, the following powders are prepared: Mo powder with a purity of 99.99% and an average particle size of 6 μm; Ni-50 atomic % Ti alloy powder with a purity of 99.9% and an average particle size of 60 μm produced by the atomization method.

[0068] Each powder was weighed so that it could form the component of the said Mo alloy sputtering target material, and it mixed using the cross rotary mixer, and the mixed powder was obtained. After that, fill it into a mild steel container with an inner diameter of 133mm, a height of 30mm, and a thickness of 3mm, heat it at 450°C for 10 hours for degassing, then seal the mild steel container, and keep it at 1000°C and 148MPa for 5 hours using a HIP device Sintered. After cooling, it was taken out from the HIP apparatus, and the mild steel container was removed by machining to obtain a Mo alloy sputteri...

Embodiment 3

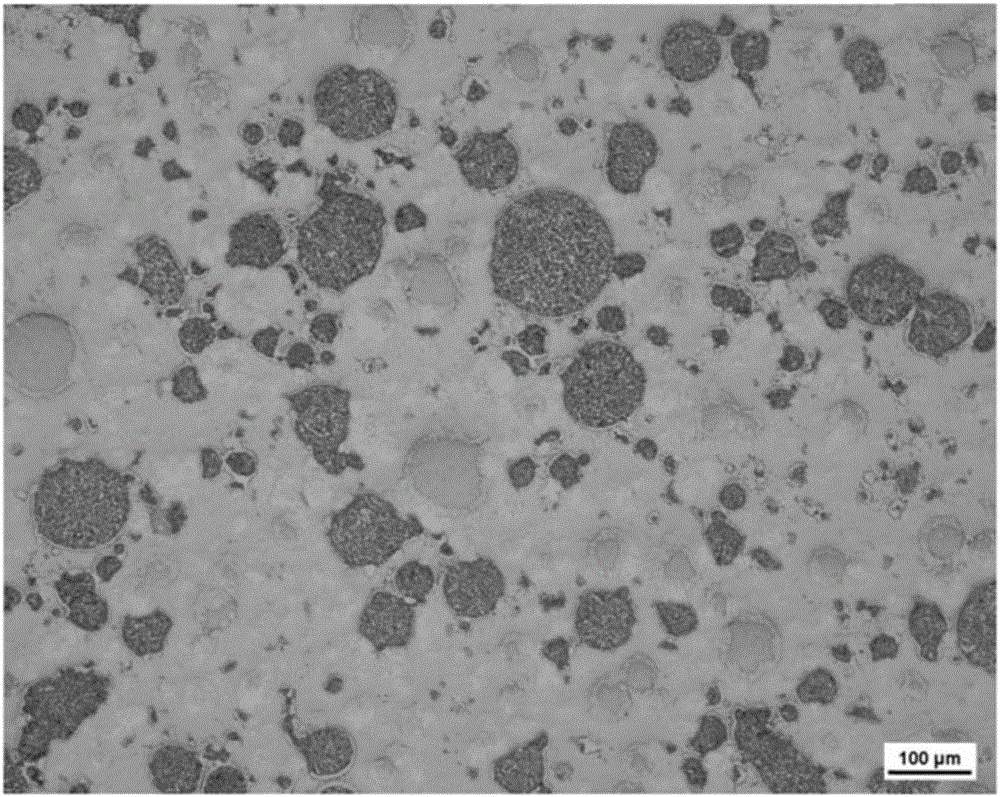

[0078] In order to make a Mo alloy sputtering target with atomic ratio of 40%Ni-10%Ti-the rest is composed of Mo and unavoidable impurities, the following powder is prepared: Mo powder with a purity of 99.99% and an average particle size of 6 μm; Ni-40 atomic % Ti alloy powder with a purity of 99.9% and an average particle size of 55 μm; Ni-20 atomic % Mo alloy powder with an average particle size of 65 μm produced by the atomization method.

[0079] Each powder was weighed so that it could form the component of the said Mo alloy sputtering target material, and it mixed using the cross rotary mixer, and the mixed powder was obtained. After that, fill it into a mild steel container with an inner diameter of 133mm, a height of 30mm, and a thickness of 3mm, heat it at 450°C for 10 hours for degassing, then seal the mild steel container, and keep it at 1000°C and 148MPa for 5 hours using a HIP device Sintered. After cooling, it was taken out from the HIP apparatus, and the mild s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com