Tobacco half-film-covering cultivation method

A cultivation method and film mulching technology, applied in the field of crop mulching cultivation, can solve the problems of delaying transplanting time, limiting the stability of flue-cured tobacco yield, improving the quality of tobacco leaves, uneven distribution of rainfall, etc. for normal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

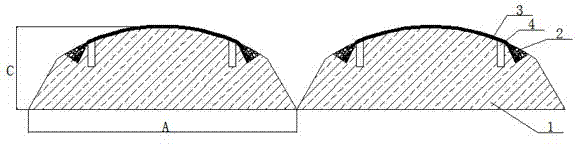

[0017] Example 1: Such as figure 1 As shown, the specific implementation steps of the present invention are

[0018] (1) Site selection: select a smoke field with a soil depth of 30cm or more and a gentle terrain;

[0019] (2) Land preparation: deep ploughing before ridge formation, the depth of ploughing layer is above 15cm, and rake evenly after ploughing to remove debris in tobacco field;

[0020] (3) Ridging: Open a trapezoid wide ridge according to the bottom of the ridge (A) 210cm. The height of the soil smoke ridge (C) is 20±3cm, and the height of the tobacco ridge (C) is 25±3cm. Does not collect rain;

[0021] (4) Apply base fertilizer: open a 15-20cm fertilizing ditch 2 at the shoulder of ground ridge 1, 50 cm from the center line of ground ridge 2, and apply the amount of base fertilizer according to conventional flue-cured tobacco rods;

[0022] (5) Film mulching: Cover the center of the ridge surface with a mulching film 3 with a width of 100 cm and a thickness of 0.008 cm....

Embodiment 2

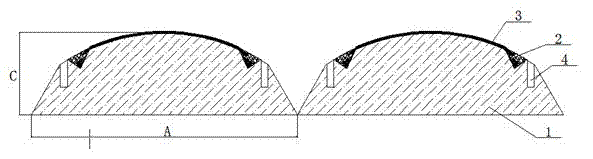

[0026] Example 2: Such as figure 2 As shown, the specific implementation steps of the present invention are

[0027] (1) Site selection: select a smoke field with a soil depth of more than 30cm and a gentle terrain;

[0028] (2) Land preparation: deep ploughing before ridge formation, the depth of ploughing layer is above 15cm, and rake evenly after ploughing to remove debris in tobacco field;

[0029] (3) Ridging: Open a trapezoid wide ridge according to the bottom of the ridge (A) 210cm. The height of the soil smoke ridge (C) is 20±3cm, and the height of the tobacco ridge (C) is 25±3cm. Does not collect rain;

[0030] (4) Apply base fertilizer: open a 15-20cm fertilizing ditch 2 at the shoulder of ground ridge 1, 50 cm from the center line of ground ridge 2, and apply the amount of base fertilizer according to conventional flue-cured tobacco rods;

[0031] (5) Film mulching: Cover the center of the ridge surface with a mulching film 3 with a width of 100 cm and a thickness of 0.008...

Embodiment 3

[0035] Example 3: Such as figure 2 As shown, the specific implementation steps of the present invention are

[0036] (1) Site selection: select a smoke field with a soil depth of 30cm or more and a gentle terrain;

[0037] (2) Land preparation: deep ploughing before ridge formation, the depth of ploughing layer is above 15cm, and rake evenly after ploughing to remove debris in tobacco field;

[0038] (3) Ridging: Open a trapezoid wide ridge according to the bottom of the ridge (A) 210cm. The height of the soil smoke ridge (C) is 20±3cm, and the height of the tobacco ridge (C) is 25±3cm. Does not collect rain;

[0039] (4) Apply base fertilizer: open a 15-20cm fertilization ditch 2 at the shoulder of ground ridge 1, 45 cm from the center line of ground ridge 2, and apply the amount of base fertilizer according to conventional flue-cured tobacco rods;

[0040] (5) Film mulching: Cover the center of the ridge surface with a mulching film 3 with a width of 90 cm and a thickness of 0.008 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com