Method for reducing releasing quantity of carbon monoxide (CO) paper-making process reproducing tobacco leaf smoke

A technology for reconstituting tobacco leaves and papermaking, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of no corresponding reduction in CO emission, affecting product qualification rate, reducing tar emission and other problems, achieving low price, small addition ratio, Guaranteed source effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

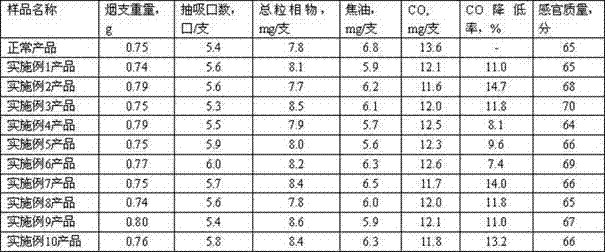

Examples

Embodiment 1

[0020] Add 1% (relative to absolute dry pulp) hydrated iron oxide to the pulp of reconstituted tobacco leaves by the papermaking method, stir and mix evenly, and then carry out the papermaking and molding of the pulp to obtain the reconstituted tobacco leaf base, which is dip-coated with the coating solution Afterwards, dry and tear the sheets to obtain reconstituted tobacco leaf products.

[0021] Cut the reconstituted tobacco products into shreds, roll the reconstituted tobacco samples on the experimental cigarette rolling machine (the weight of a single cigarette sample satisfies 0.77±0.03g), and smoke the samples at 22±1 o C, placed in an environment with a relative humidity of 60±2% for 48 hours, and tested the smoke components on a rotary smoking machine, the results are shown in Table 1.

Embodiment 2

[0023] Add 2% (relative to absolute dry pulp) iron oxide to the pulp of reconstituted tobacco leaves by papermaking method, stir and mix evenly, and then carry out the papermaking and molding of the pulp to obtain the reconstituted tobacco leaf base, which is prepared by dip coating After the liquid cloth is dried, the sheets are torn to obtain reconstituted tobacco leaf products. The preparation of smoke samples and detection of smoke components are the same as in Example 1.

Embodiment 3

[0025] Add 5% (relative to absolute dry pulp) hydrated iron oxide to the pulp of reconstituted tobacco leaves by papermaking method, stir and mix evenly, and then carry out papermaking and molding of the pulp to obtain the reconstituted tobacco leaf base, which is prepared by dip coating After the coating solution is dried, the sheets are torn to obtain reconstituted tobacco leaf products. The preparation of smoke samples and detection of smoke components are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com