Turning fixture for gleason spiral bevel gear

A gear turning and arc tooth technology, which is applied in turning equipment, turning equipment, positioning devices, etc., can solve the problems of poor control of the back and forth movement of the grinding wheel, low efficiency, and difficulty in production, and meet the requirements of ensuring consistency and shape and position error. As well as gear accuracy requirements, avoiding benchmark conversion errors, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

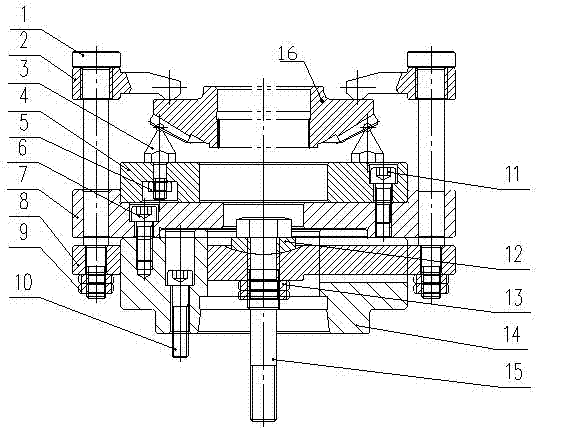

[0010] The present technology will be further described below through the embodiments in conjunction with the accompanying drawings.

[0011] Such as figure 2 As shown, the fixture is connected with the spindle of the CNC lathe CK7516 by the fixture seat 14 through the screw 10, and the fixture body 7, the support plate 4, and the positioning ball 3 are connected into one body with the screw 11 and the nut 5 and connected to the fixture seat 14 by the screw 6 and connected with the machine tool. The main shaft forms a fixed rotating body, which ensures that the support plate is consistent with the center of rotation of the main shaft of the machine tool;

[0012] The pressing plate 2 is mounted on the pull rod 1 and can rotate freely through threaded connection, and the pull rod 1 is fixed on the fork plate 8 through a round nut 9 to form a movable adjustment body that can move up and down.

[0013] The movable slider 12 is mounted on the central screw 15 and connected to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com