Corrugated steel plate coating device and coating method thereof

A technology of corrugated steel plate and lamination device, applied in lamination device, chemical instrument and method, lamination auxiliary operation, etc., can solve the problems of increased extrusion force, tearing, abrasion of HDPE plastic film, peeling of corrugated steel plate, etc. , to save energy, reduce pollution and prevent oxidation of zinc layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

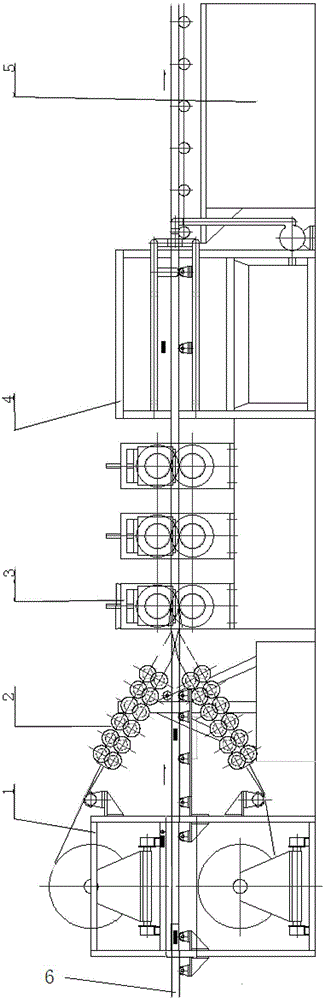

[0024] Such as figure 1 As shown, the device includes a feeder 1 connected in sequence, a guide machine 2 for preforming plastic sheets, a laminating roller machine 3, a cooling box 4 and a discharge bracket 5, and the feed bracket 6 passes through the agencies.

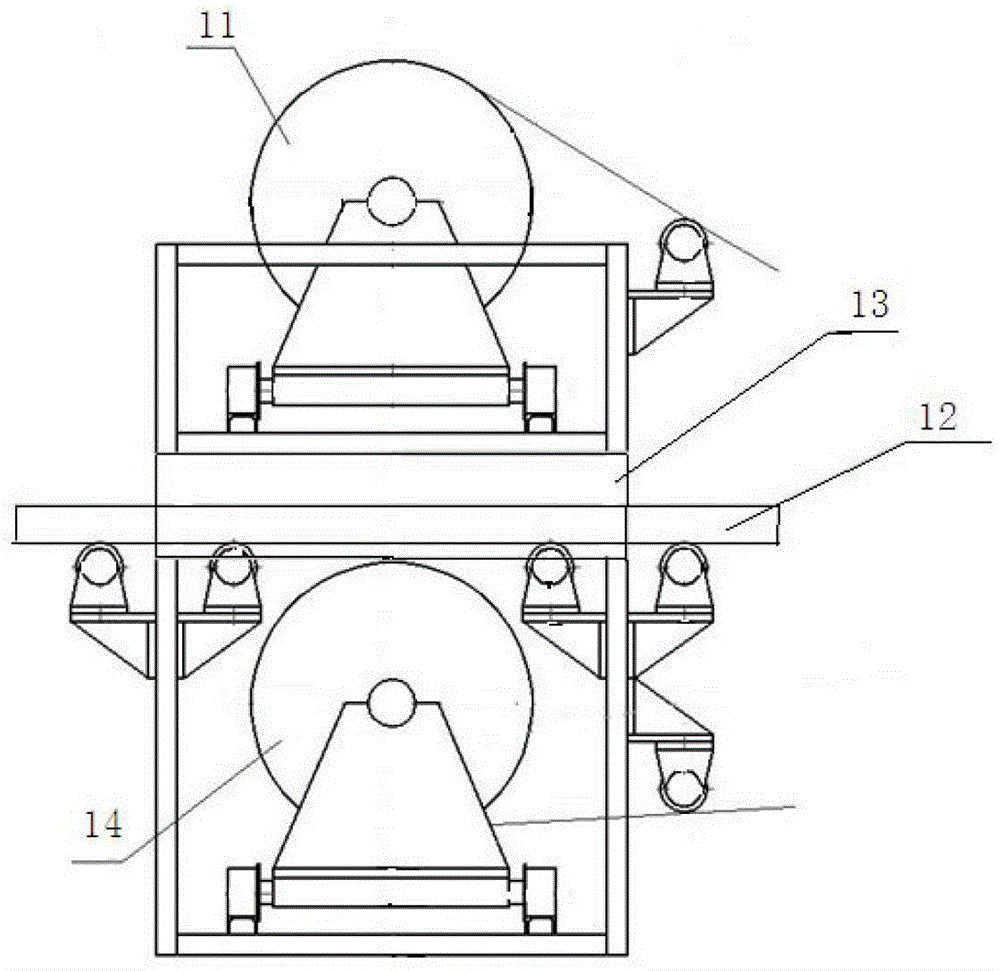

[0025] Such as figure 2 As shown, the feeder 1 includes an upper unwinder 11 and a lower unwinder 14, the feeding bracket 6 between the two is placed in a thermostat 13, and the temperature sensor in the thermostat 13 can monitor the temperature of the corrugated steel plate in real time , to ensure that the temperature of the corrugated steel plate is maintained at 130°C.

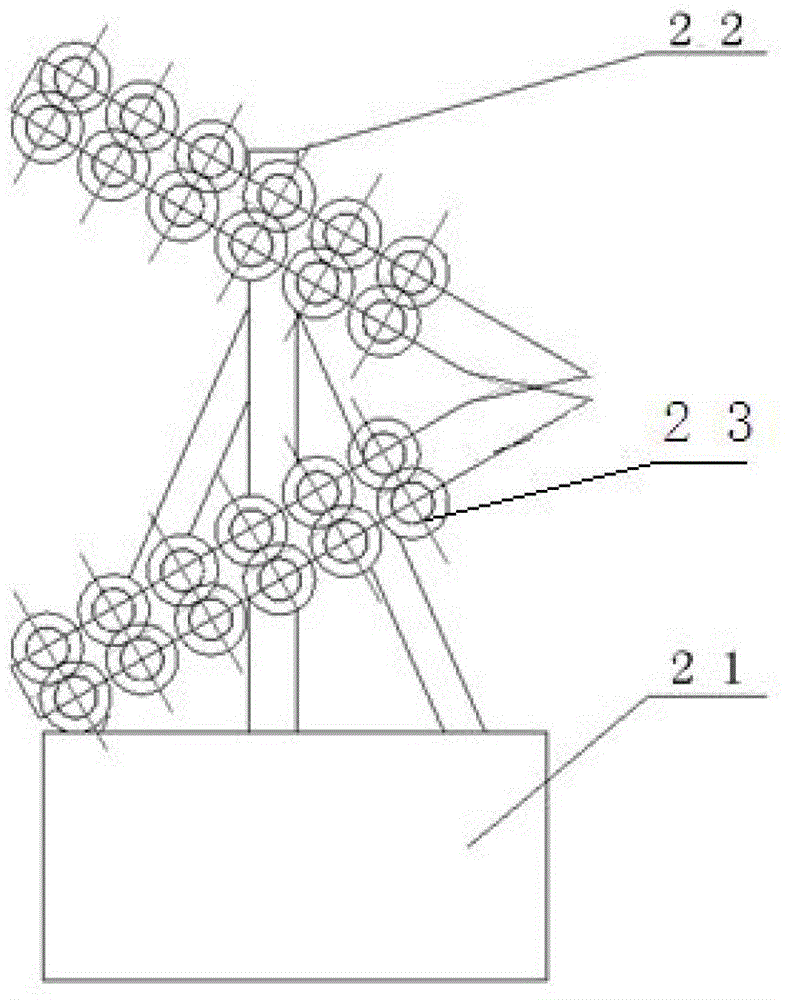

[0026] Such as image 3 , 4 As shown, the guide machine 2 includes a support frame 21 and an upper wave pressure wheel 22 and a lower wave pressure wheel 23 installed on the support frame 21. The two brackets where the upper and lower wave wheels are located are brought together. Preforming, the upper and lower plastic sheets after the pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com