Radiographic Measurement Method of Film Thickness Distribution and Its Uniformity

A measurement method and technology of film thickness, which are applied in measurement devices, use of wave/particle radiation, material analysis using radiation, etc., can solve the problems of lack of measurement methods and measurement methods for the uniformity of film mass and thickness distribution, and achieve stable measurement results. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

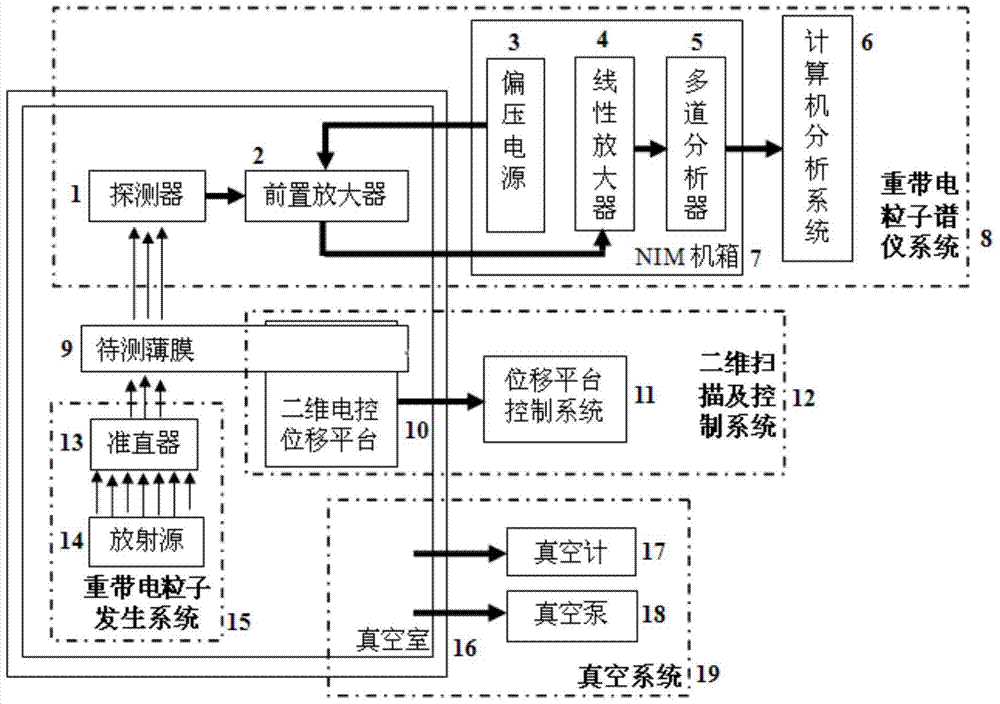

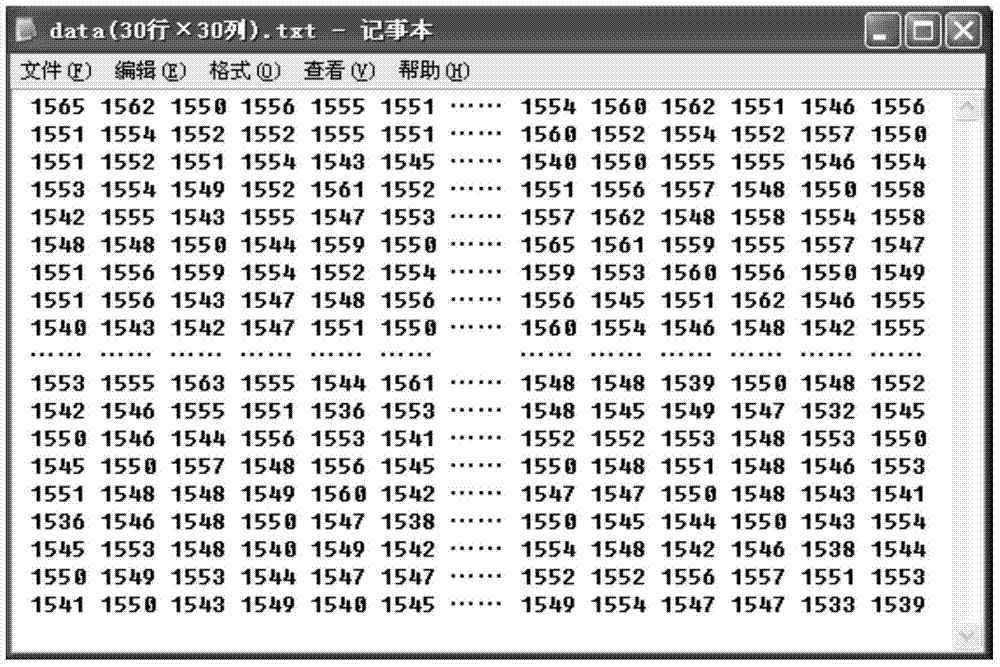

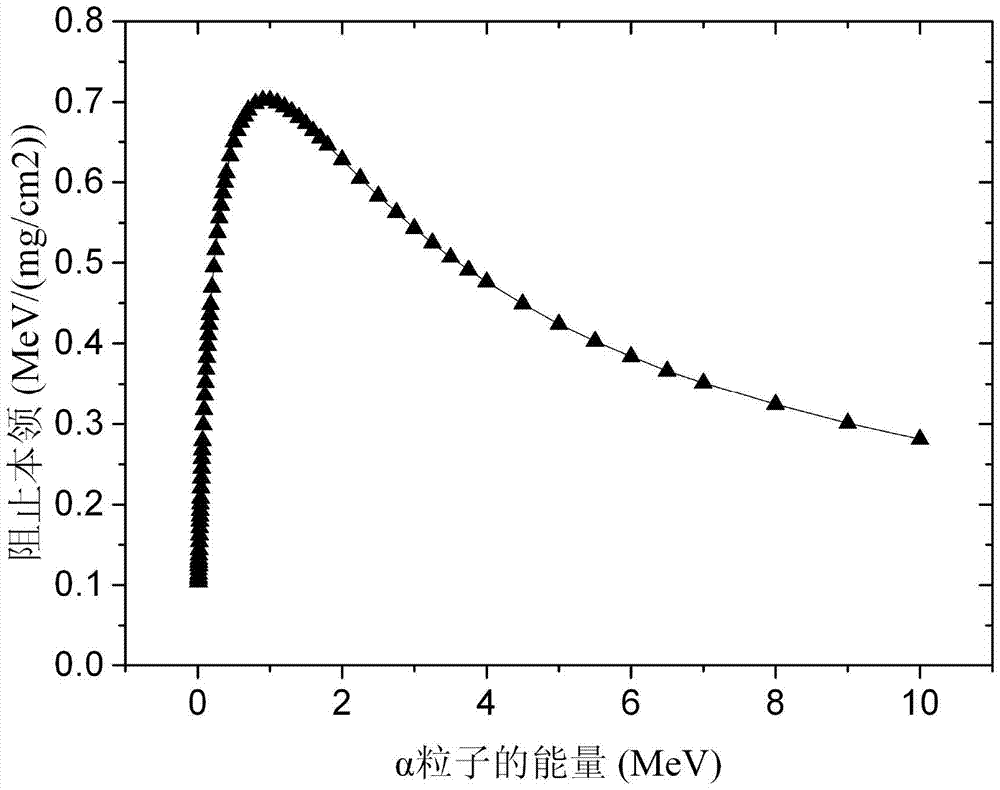

[0037] The construction process of the measuring device used in the measurement method of film mass thickness distribution and its uniformity described in this embodiment: the radiation source 14 and the two-dimensional electronically controlled displacement platform 10 are respectively installed on the bottom of the vacuum chamber 16 through the bracket, and the radiation source Place the collimator 13 above the collimator 14, so that the heavy charged particles emitted by the radioactive source 14 shoot the heavy charged particle beam vertically upwards along the collimation hole of the collimator 13; To measure the thin film 9, the heavy charged particle beam emitted from the collimator 13 is vertically incident and passes through the thin film 9 to be measured; a detector 1 is installed in the direction in which the thin film 9 to be measured emits the heavy charged particle beam, and the signal on the detector 1 is output The line is connected to the preamplifier 2; outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com