Conveyor belt special for quick connector and preparation method thereof

A conveyor belt, fast technology, applied in the field of conveyor belts, can solve the problems of conveying equipment damage and difficulty in implementation, and achieve the effect of simple tools, short time consumption, and reduced downtime and maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

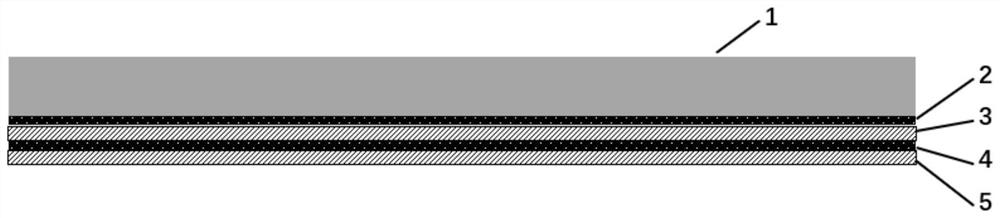

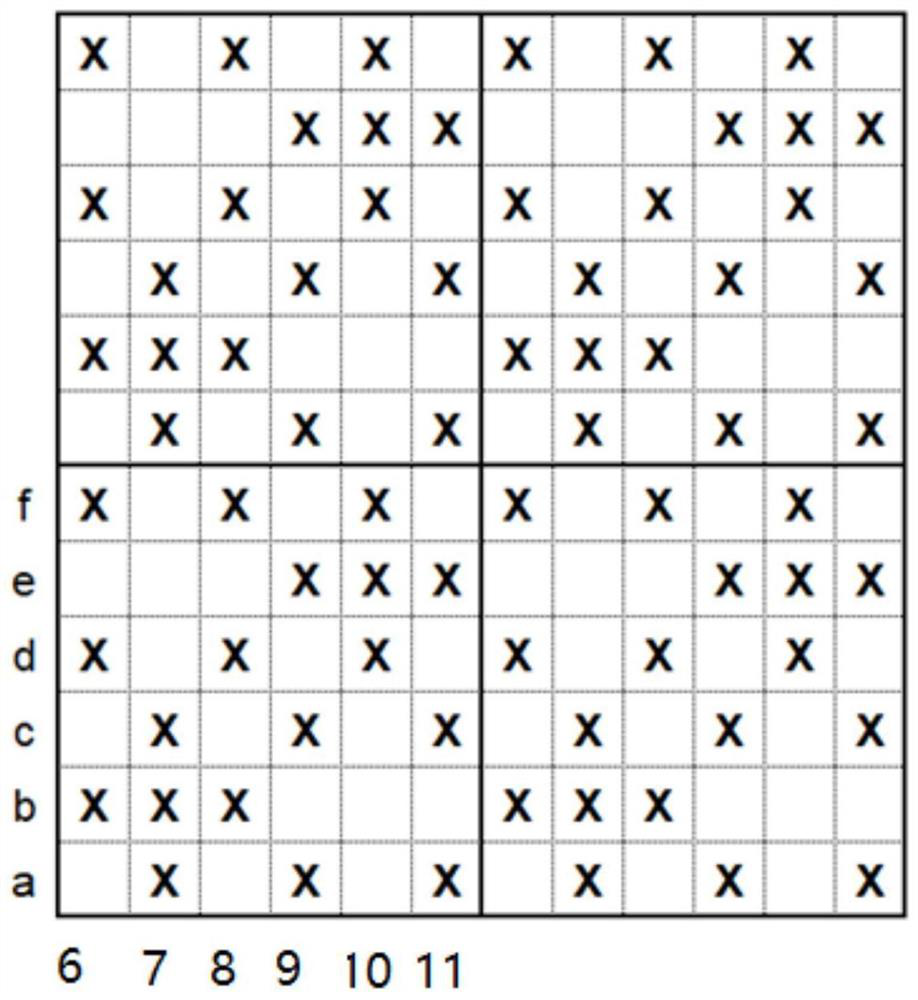

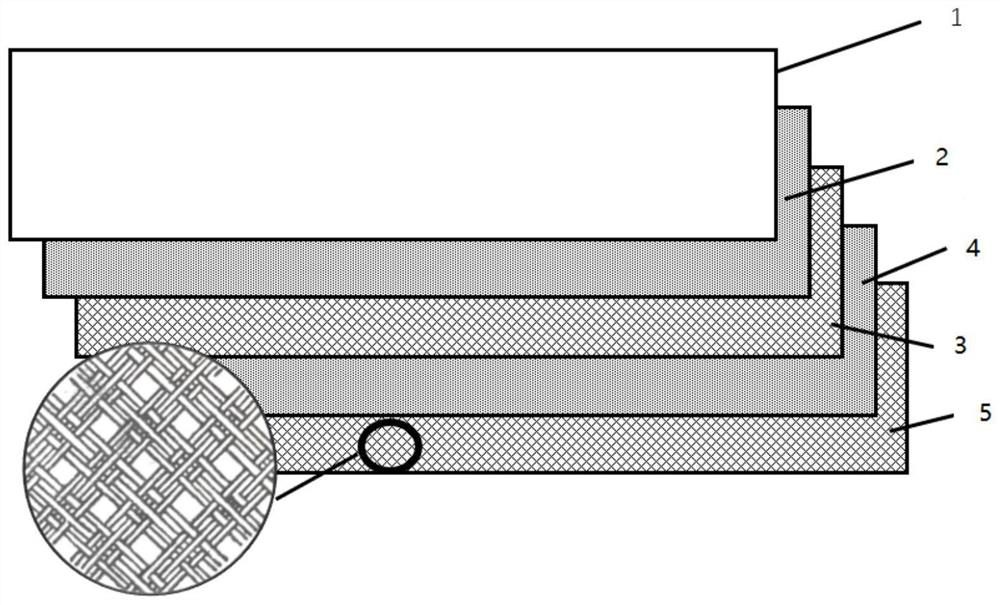

[0038] Such as Figure 1-4 As shown, this embodiment provides a special conveyor belt for quick connectors, wherein: the conveyor belt sequentially includes a cover rubber layer 1, a first adhesive layer 2, a first dipped canvas layer 3 for quick connectors, The second glue layer 4 and the second quick connector special dipped canvas layer 5, the first quick joint special dipped canvas layer 3 and the second quick joint special dipped canvas layer 5 are composed of several repeated unit organizations , each unit weave is formed by interweaving warp and weft yarns. in figure 2 Middle: the warp is represented by X, and the weft is represented by □; image 3 Among them, the first quick connector special dipping canvas layer 3, the second quick joint special dipping canvas layer 5 canvas layer latitude and longitude lines all form an angle of 45° with the running direction of the conveyor belt.

[0039] Wherein: the components are calculated in parts by weight, and the coverin...

Embodiment 2

[0051] Such as Figure 1-4 As shown, this embodiment provides a special conveyor belt for quick connectors, wherein: the conveyor belt sequentially includes a cover rubber layer 1, a first adhesive layer 2, a first dipped canvas layer 3 for quick connectors, The second glue layer 4 and the second quick connector special dipped canvas layer 5, the first quick joint special dipped canvas layer 3 and the second quick joint special dipped canvas layer 5 are composed of several repeated unit organizations , each unit weave is formed by interweaving warp and weft yarns.

[0052] Wherein: the components are calculated in parts by weight, and the covering adhesive layer 1, the first adhesive layer 2 and the second adhesive layer 4 all include 60 parts of natural rubber, 30 parts of styrene-butadiene rubber, 5 parts of zinc oxide, stearic acid 1.5 parts, 1.5 parts of sulfur, 1 part of accelerator M, 1 part of accelerator CZ, 50 parts of Zhongchao wear-resistant carbon black, 10 parts ...

Embodiment 3

[0064] Such as Figure 1-4 As shown, this embodiment provides a special conveyor belt for quick connectors, wherein: the conveyor belt sequentially includes a cover rubber layer 1, a first adhesive layer 2, a first dipped canvas layer 3 for quick connectors, The second glue layer 4 and the second quick connector special dipped canvas layer 5, the first quick joint special dipped canvas layer 3 and the second quick joint special dipped canvas layer 5 are composed of several repeated unit organizations , each unit weave is formed by interweaving warp and weft yarns.

[0065] Wherein: the components are calculated in parts by weight, and the covering adhesive layer 1, the first adhesive layer 2 and the second adhesive layer 4 all include 80 parts of natural rubber, 60 parts of styrene-butadiene rubber, 8 parts of zinc oxide, stearic acid 2 parts, 2.5 parts of sulfur, 2 parts of accelerator M, 1.5 parts of accelerator CZ, 60 parts of Zhongchao wear-resistant carbon black, 15 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com