Novel pen cap, preparation method thereof and pen with novel pen cap

A pen cap and a new type of technology, applied in the field of writing pens, can solve the problems affecting the convenience and effect of erasing, the friction body falling off or deforming, and occupying the axial space inside the writing tool, so as to improve elasticity, safety and comfort. The effect of hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

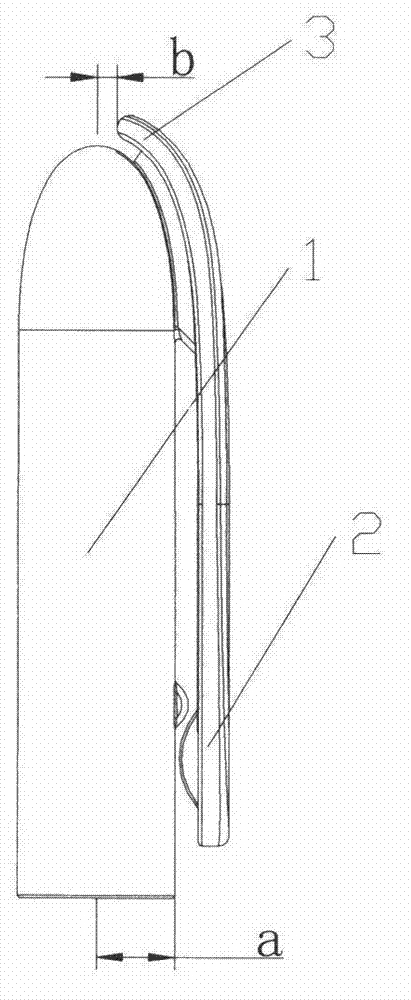

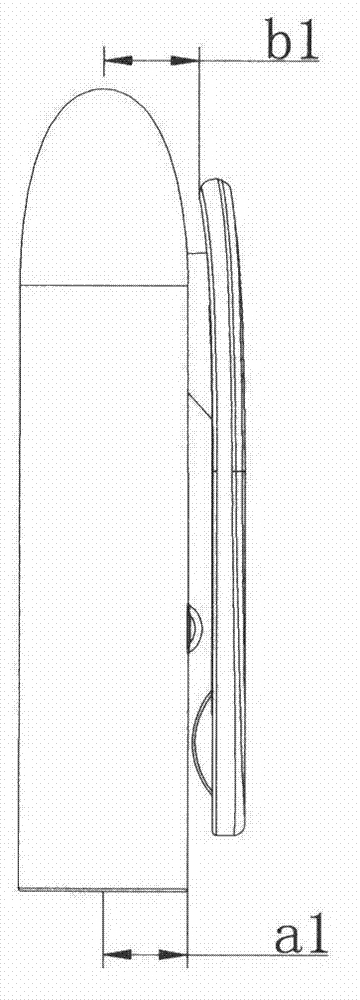

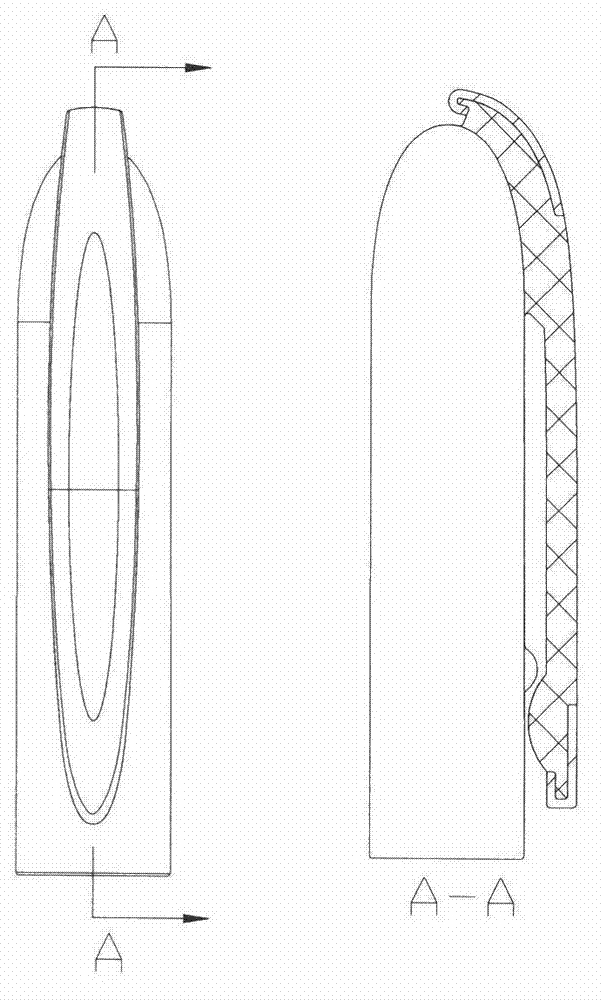

[0033] Example 1, such as figure 1 As shown, this embodiment discloses a new type of pen cap, which includes a pen cap body 1 and a pen clip 2 installed on the pen cap using a cantilever beam structure. The top end 3 of the pen clip is covered with a thermoplastic elastomer. The covering can also be integral covering, and the shortest radial distance between the area covered by the thermoplastic elastomer and the central axis of the pen cap is less than or equal to the inner radius of the pen cap.

[0034] In this embodiment, since the top end of the clip is covered with a thermoplastic elastomer with better touch, when the finger touches the clip, it feels good and does not slip. Wherein, the end of the pen holder close to the fulcrum and away from the clamp is the top end of the pen holder. The central axis of the pen cap is the central line of the main part of the writing pen such as the pen core or the pen holder. When the shortest radial distance between the area covere...

Embodiment 2

[0042] Example 2, such as Figure 8-9 As shown, this embodiment discloses a writing pen, which uses the cap disclosed in the above embodiments.

[0043] Since there is a thermoplastic elastomer covering layer on the clip of the pen cap, and the clip generally protrudes from the top of the pen cap or its connecting part, there is a large space to realize shapes with different curvatures, so that when using the inherent heat conduction of thermoplastic elastomers And friction performance, it can adapt to different angles for friction or erasing.

Embodiment 3

[0044] Example 3. This example discloses a method for preparing a pen cap. A pen clip with a cantilever beam structure is installed on the pen cap. The pen clip is formed by two-color injection molding, and the part formed by plastic injection molding for the first time is used for support and assembly, specifically as Figure 10 As shown, the second time the thermoplastic elastomer is used to form the surface covering, as shown in Figure 11 As shown, the thermoplastic elastomer of the second injection molding is required to have good bonding performance with the material of the first injection molding, and the two will not be easily delaminated or peeled off.

[0045] The materials used for the first injection include one or more of polycarbonate, polymethyl methacrylate, styrene-butadiene-acrylonitrile copolymer, and polyoxymethylene.

[0046] The second use of thermoplastic elastomers includes one or more of styrene-based elastomers, polyurethane elastomers, and polyamide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com