Aluminum alloy van transportation semitrailer car

A technology of semi-trailer and aluminum alloy, which is applied in the direction of transportation and packaging, vehicle parts, and the upper structure of trucks, etc. It can solve the problems of reduced service life of the carriage, low residual value of the steel floor, and easy corrosion of the floor of the carriage. Enhanced bearing capacity, improved service life, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

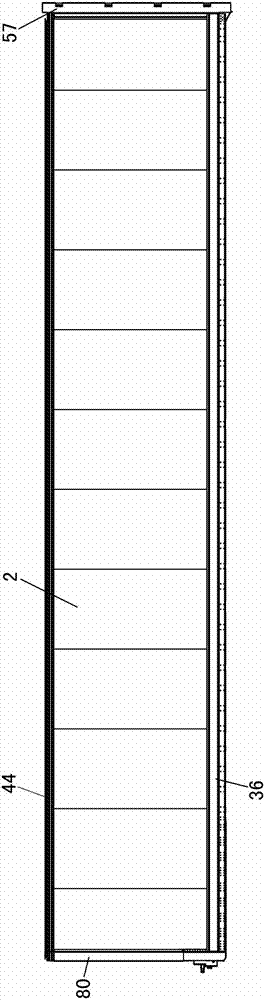

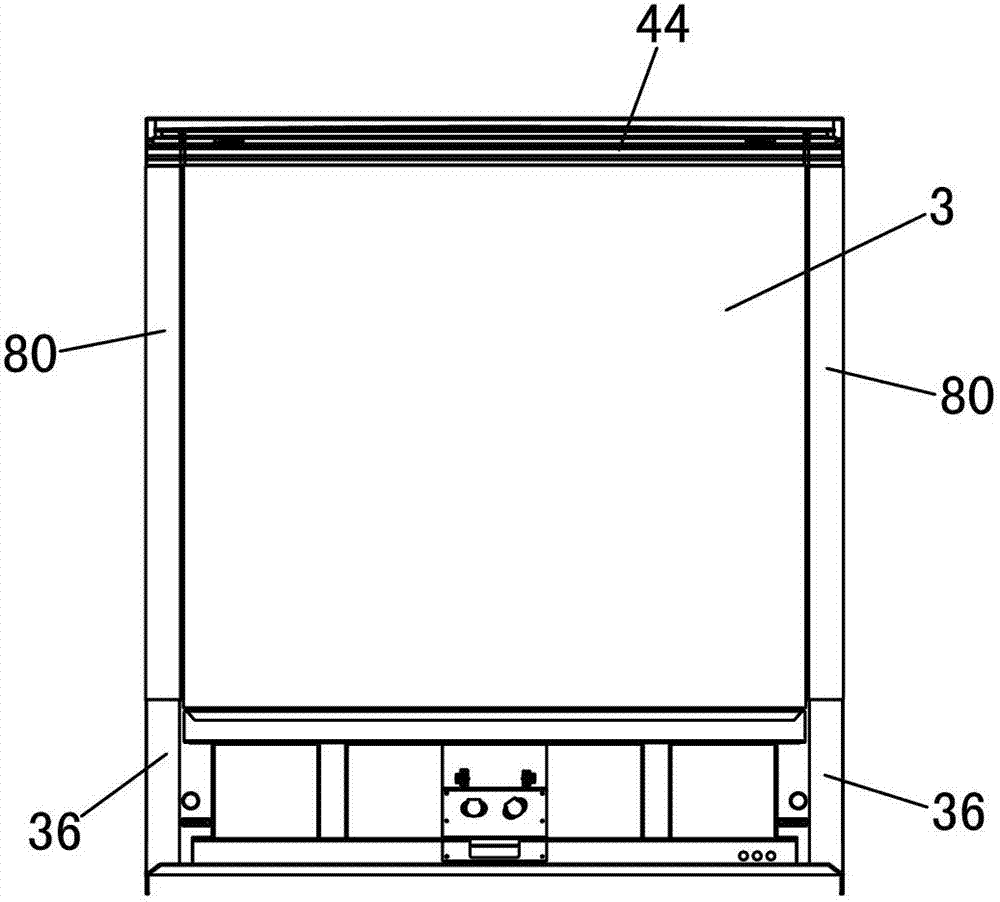

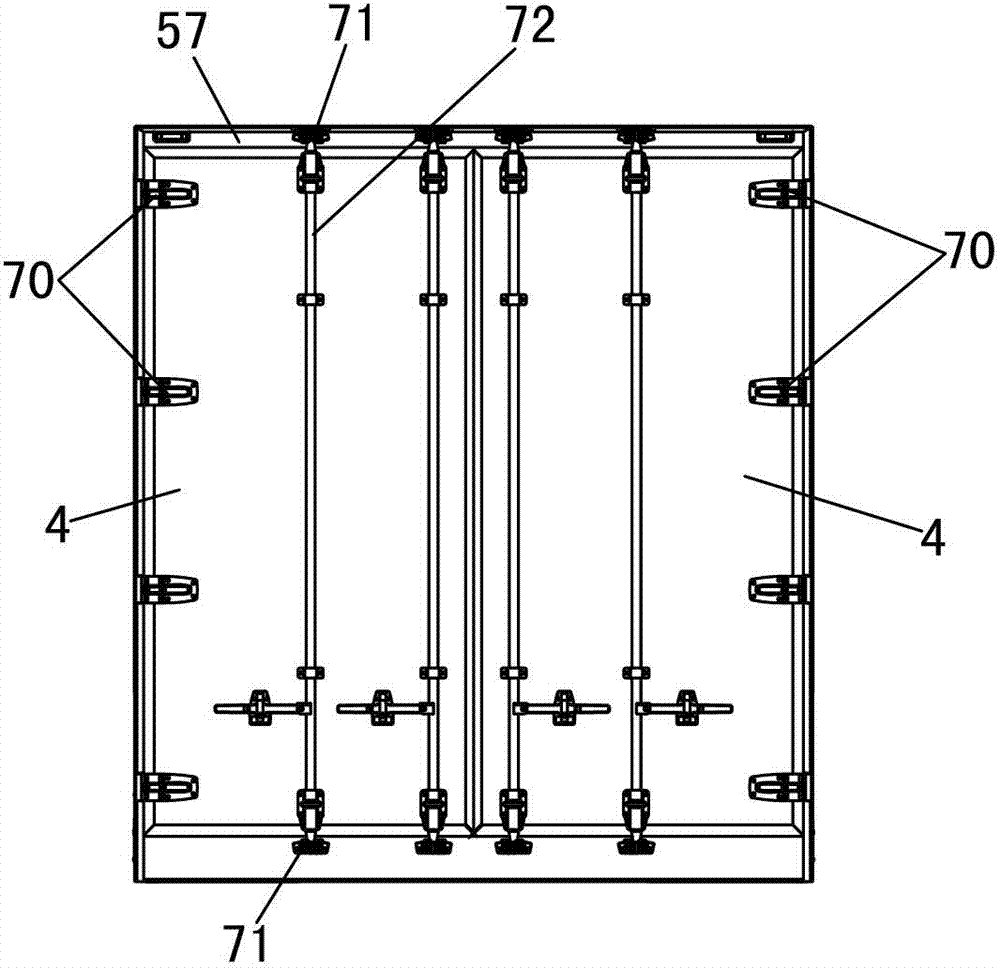

[0045] Such as Figure 1 to Figure 22 As shown, the aluminum alloy van transport semi-trailer compartment of the present invention is composed of a bottom plate 1, two side plates 2 with symmetrical structure left and right, a front plate 3, a rear door plate 4 installed in the inner cavity of the rear door frame, and a top plate 5. .

[0046] combine Figure 4 to Figure 9 As shown, the bottom plate 1 is made of aluminum alloy material. It includes a first profile 6 , three second profiles 7 , three third profiles 8 , and a fourth profile 9 and a fifth profile 10 with left-right symmetrical shapes. The three second profiles 7 are connected to each other, and the rightmost second profile 7 is connected to the left side of the first profile 6 . The three third profiles 8 are connected to each other. The leftmost third profile 8 is connected to the right side of the first profile 6 . The shapes of the second profile 7 and the third profile 8 are left and right symmetrical. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com