Spatial microgravity simulation experiment system

A technology of microgravity simulation and experimental system, which is applied to the simulation device of space navigation conditions, space navigation equipment, transportation and packaging, etc. Promotion and other issues, to achieve the effect of convenience, feasibility and wide promotion, reusable structure, and easy wide promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

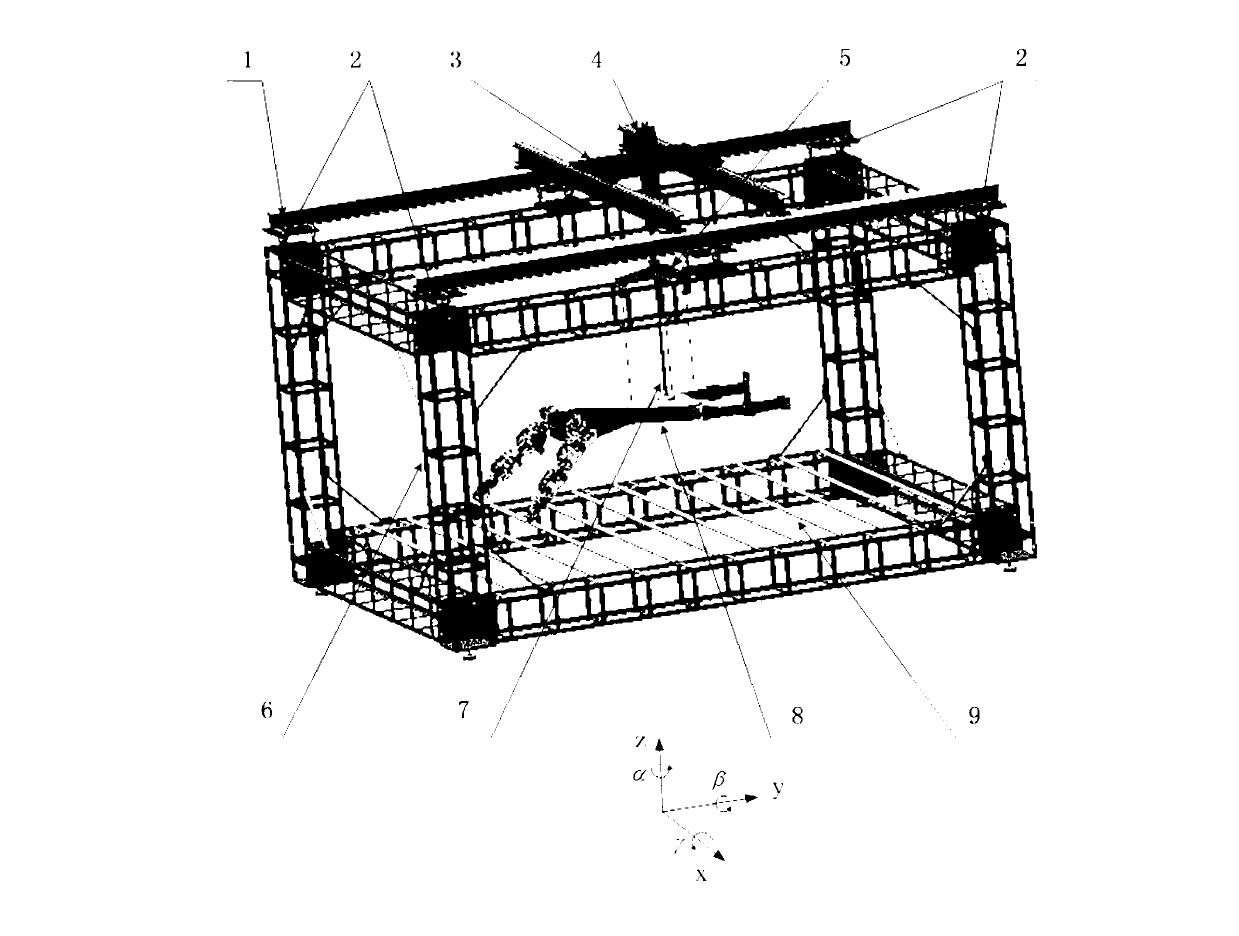

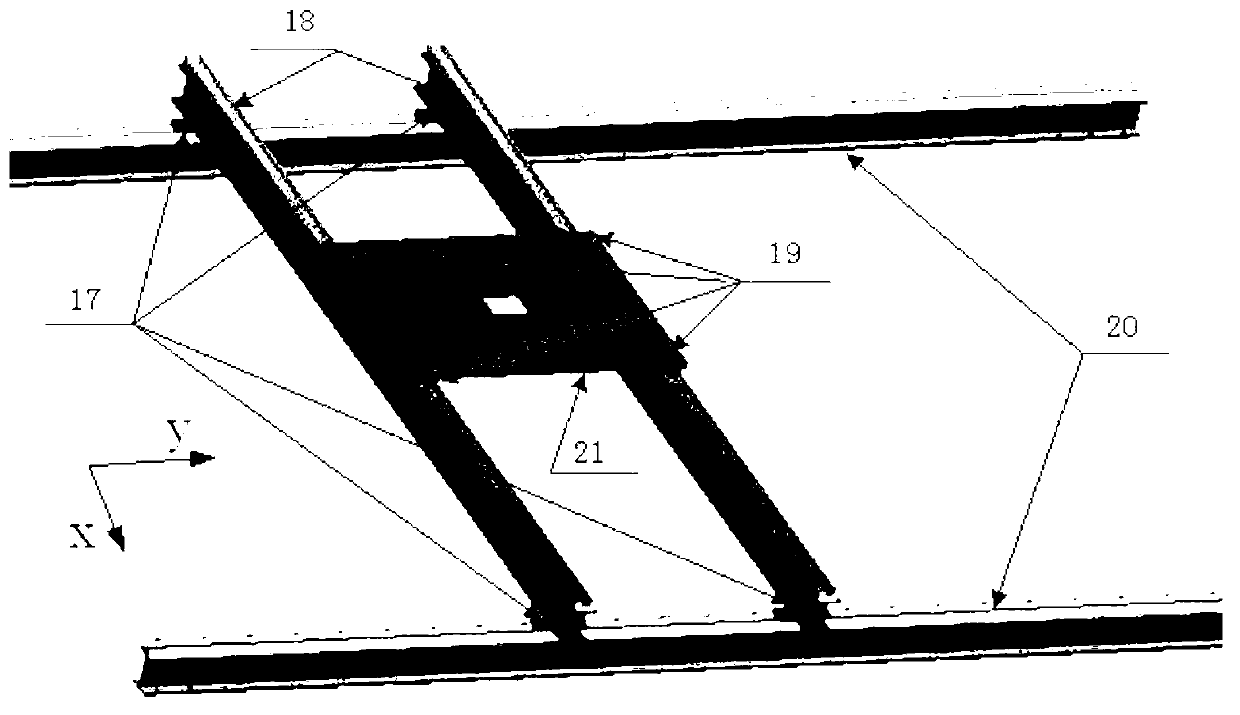

[0045] exist figure 1 The space microgravity simulation experiment system consists of a peripheral frame, a leveling system 2, a passive adjustment mechanism in the horizontal plane 3, a Z-direction active gravity compensation system 4, a slewing passive adjustment mechanism 5, and a pitch and deflection active adjustment system 7.

[0046] The peripheral frame includes an upper platform 1 , a lower platform 9 and four pillars 6 . The upper platform 1 is used to place the passive adjustment mechanism 3 in the horizontal plane, and 12 handrails are arranged on the lower platform to simulate the size and arrangement of the handrails outside the space station; The floor platform and the four uprights are welded with angle steel, which can provide sufficient rigidity for the platform.

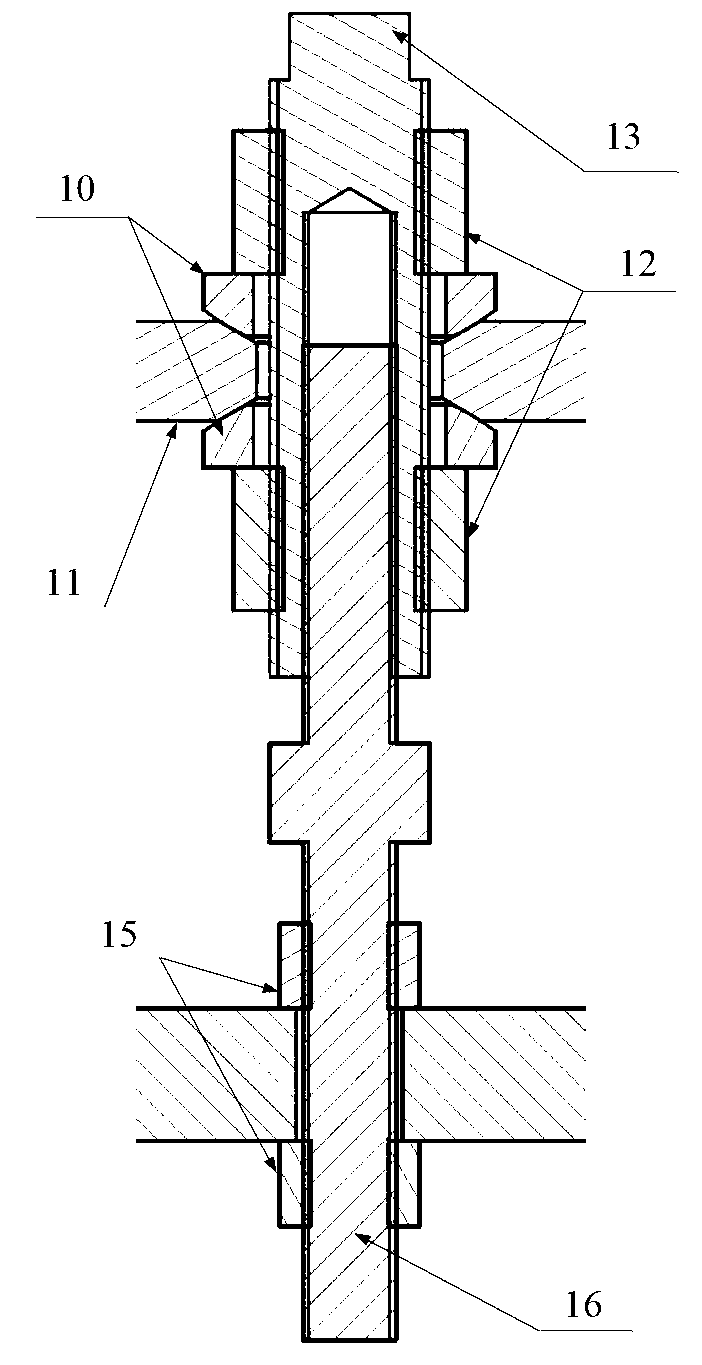

[0047] The leveling system 2 consists of two parts: a coarse leveling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com