Modified Y type molecular sieve

A molecular sieve and modification technology, applied in the direction of octahedral crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of product distribution deterioration, conversion activity reduction, etc., to reduce toxicity and improve activity stability , Significant effect of alkali nitrogen resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

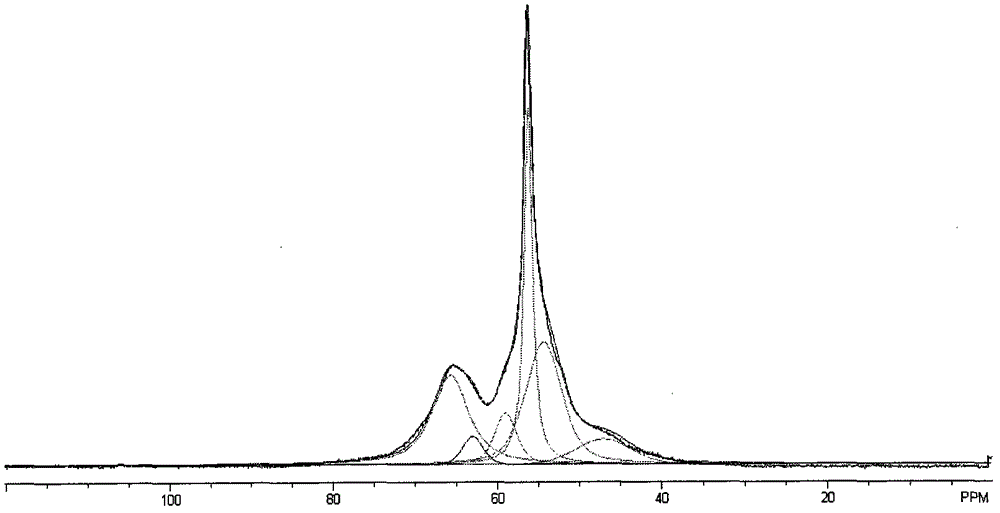

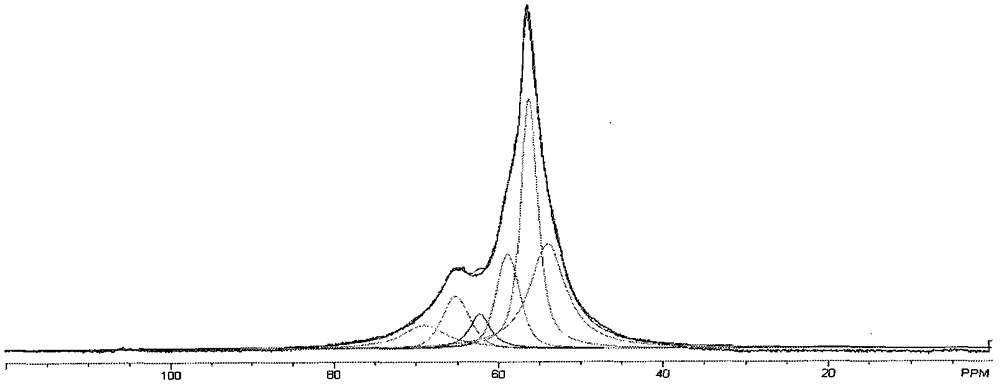

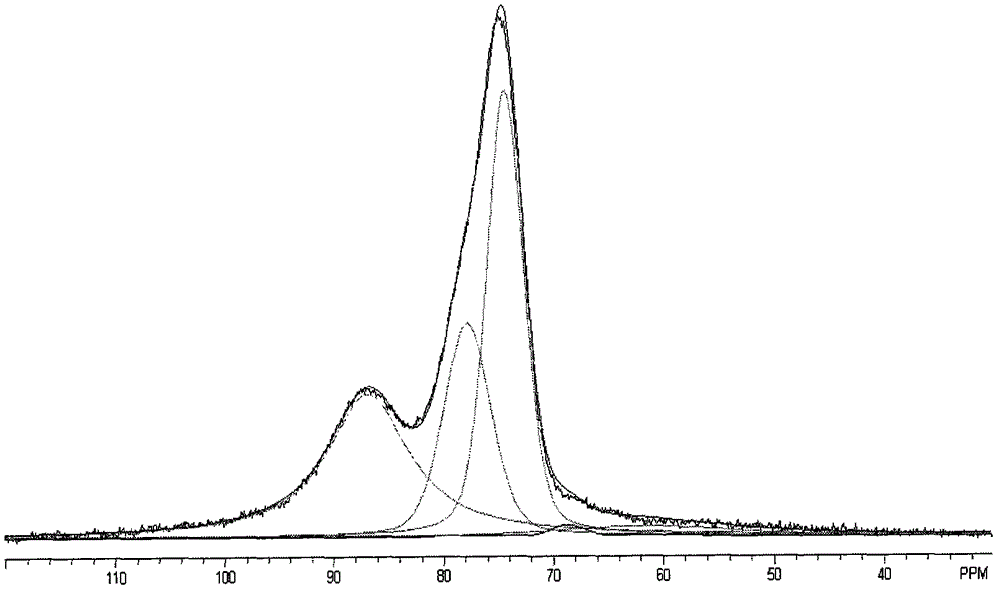

Image

Examples

Embodiment 1

[0027] Add 5.0 kilograms of NaY molecular sieve (provided by Changling Catalyst Factory, crystallinity 86%, framework silicon-aluminum ratio 5.2) and 4 kilograms of deionized water into the reactor, and slowly add 2.50 liters of rare earth chloride solution (Qilu) under vigorous stirring. Provided by catalyst factory, RE 2 O 3 The content is 222.5 g / l), adjust the pH of the system with 4% dilute hydrochloric acid to 3.5, heat up to 90°C and stir for 1.5 hours, filter, wash, and dry; then calcinate at 550°C for 2 hours to produce "one-pass one-baking" Rare earth sodium is recorded as modified molecular sieve ABY-1A.

[0028] Take 2.0 kg of modified molecular sieve ABY-1A dry basis and put it into the reactor, add 1.6 kg of deionized water, slowly add 0.48 liters of rare earth chloride, 80 grams of Fe(NO 3 ) 3 ·9H 2 O solid, 100 grams of ammonium chloride, adjust the system pH=3.5 with 4% dilute hydrochloric acid, heat up to 90°C and stir for 1 hour, filter, wash, and dry to obtain ...

Embodiment 2

[0038] Add 5.0 kilograms of NaY molecular sieve (provided by Changling Catalyst Factory, crystallinity 86%, framework silicon-to-aluminum ratio 5.2) and 4 kilograms of deionized water into the reactor, and slowly add 4.20 liters of rare earth chloride solution (Qilu) under vigorous stirring. Provided by catalyst factory, RE 2 O 3 The content is 222.5 g / l), adjust the pH of the system with 4% dilute hydrochloric acid to 3.5, heat up to 90°C and stir for 1.5 hours, filter, wash, and dry; then calcinate at 550°C for 2 hours to produce "one-pass one-baking" Rare earth sodium Y is recorded as modified molecular sieve ABY-2A.

[0039] Take 2.0 kg of modified molecular sieve ABY-2A dry basis and put it into the reactor, add 1.6 kg of deionized water, slowly add 0.48 liters of rare earth chloride, 125 g of Fe(NO 3 ) 3 ·9H 2 O solid, 100 grams of ammonium chloride, adjust the system pH=3.5 with 4% dilute hydrochloric acid, heat up to 90°C and stir for 1 hour, filter, wash, and dry to obtai...

Embodiment 3

[0049] Add 5.0 kilograms of NaY molecular sieve (provided by Changling Catalyst Factory, crystallinity 86%, framework silicon-aluminum ratio 5.2) and 4 kilograms of deionized water into the reactor, and slowly add 5.12 liters of rare earth chloride solution (Qilu) under vigorous stirring. Provided by catalyst factory, RE 2 O 3 The content is 222.5g / L), adjust the system pH=3.5 with 4% dilute hydrochloric acid, heat to 90℃ and stir for 1.5 hours, filter, wash, and dry; then calcinate at 650℃ and 100% steam atmosphere for 2 hours to prepare "One cross one baking" rare earth sodium Y is recorded as modified molecular sieve ABY-3A.

[0050] Take 2.0 kilograms of modified molecular sieve ABY-3A dry basis and put it into the reactor, add 1.6 kilograms of deionized water, slowly add 1.44 liters of rare earth chloride, 210 grams of Fe(NO 3 ) 3 ·9H 2 O solid, adjust the system pH=3.5 with 4% dilute hydrochloric acid, raise the temperature to 90°C and stir for 1 hour, filter, wash, and dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com