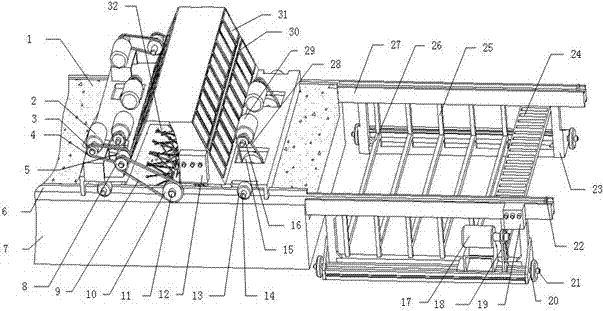

Full-automatic walking type turner

A walking type, turning and throwing machine technology, applied in the field of agricultural machinery, can solve the problems of thick rolling diameter, low turning and throwing output, short chain life, etc., and achieve the effects of thorough material turning, high personnel utilization rate, and stable equipment operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0021] When the turning and throwing machine is working, the control button on the automatic control box 12 is pressed to the upper position, and the turning and throwing drive motor 2 installed on the truss 31 works to drive the driving sprocket 3 connected with the motor output shaft to rotate; the driving sprocket 3 passes through the chain 4 drives the driven sprocket 5 to rotate, and the driving sprocket 8 on the same shaft rotates, drives the driven sprocket 10 to rotate through the chain 9, realizes the purpose of deceleration, and transmits the decelerated rotating speed to the turning shaft 11, at this time Rake teeth 32 are staggered on the circumference to rotate the turning shaft 11 to realize the in-situ turning action; at the same time, the walking drive motor 29 works, and the output shaft of the motor drives the driving sprocket 16 to rotate at a high speed, and the speed is transmitted to the driven sprocket through the chain 28 15, drive the output shaft 14 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com