Weather-resistance modified asphalt as well as preparation technology and application thereof

A preparation process and weather resistance technology, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of complicated preparation process, high difficulty, poor weather resistance, etc., and achieve the goal of improving preparation efficiency, using less amount, and reducing development time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

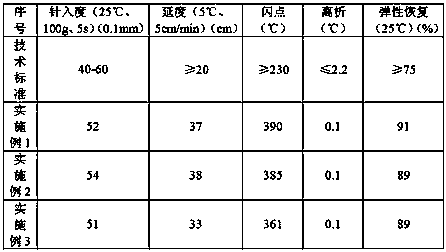

Examples

Embodiment 1

[0046] S1. Heating and melting: first add 89kg of coal tar pitch in the heating pot, heat to 125°C and maintain, stir and melt the coal tar pitch;

[0047] S2. Improved grinding: Add 5kg of linear SBS into the heating pot and stir evenly, during which the temperature remains at 125℃;

[0048] S3. Plasticization and development: Add 0.5kg of stearic acid in the heating pot, then increase the temperature to 170°C and keep it, stir it evenly and let it stand for 1.5h;

[0049] S4. Viscosity reduction development: Divide 1.5kg of silicone-fluorine viscosity reducer into three parts, among which the second part and the third part are heated after 0.5h of adding the former. The silicone-fluorine viscosity reducer is added The temperature of the heating pot is 150°C, and the last part of the silicon-fluorine viscosity reducer is evenly stirred and allowed to stand for 3.5 hours;

[0050] S5. Improved development: add 0.5kg of phthalic anhydride and 3.5kg of rubber powder activator in the hea...

Embodiment 2

[0053] S1. Heating and melting: first add 90kg of coal tar pitch in the heating pot, heat to 130°C and keep it, stir and melt the coal tar pitch;

[0054] S2. Improved grinding: Add 4kg of linear SBS into the heating pot and stir it evenly, during which the temperature remains at 130℃;

[0055] S3. Plasticization and development: Add 0.5kg of stearic acid in the heating pot, then increase the temperature to 175°C and keep it, stir it and let it stand for 2.0h;

[0056] S4. Viscosity reduction development: Divide 1.5kg of silicone-fluorine viscosity reducer into three parts, of which the second part and the third part are heated after 0.5h of adding the former. The silicone-fluorine viscosity reducer is added The temperature of the heating pot is 152°C, and the last part of the silicon-fluorine viscosity reducer is evenly stirred and allowed to stand for 3.5 hours;

[0057] S5. Improved development: add 0.5 kg of phthalic anhydride and 3.5 kg of rubber powder activator in the heating p...

Embodiment 3

[0059] S1. Heating and melting: first add 89kg of coal tar pitch in the heating pot, heat to 135°C and keep it, stir and melt the coal tar pitch;

[0060] S2. Improved grinding: Add 4kg of linear SBS into the heating pot and stir it evenly, during which the temperature is kept at 135℃;

[0061] S3. Plasticization and development: Add 0.5kg of stearic acid in the heating pot, then increase the temperature to 180°C and keep it, stir it evenly and let it stand for 2.5h;

[0062] S4. Viscosity reduction development: Divide 1.5kg of silicone-fluorine viscosity reducer into three parts, among which the second part and the third part are heated after 0.5h of adding the former. The silicone-fluorine viscosity reducer is added The temperature of the heating pot is 155°C, and the last part of the silicon-fluorine viscosity reducer is evenly stirred and allowed to stand for 4.0 hours;

[0063] S5. Improved development: add 0.5kg of phthalic anhydride and 4.5kg of rubber powder activator in the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| coking value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com