Apparatus and method for continuously separating isopropylphenol

A technology of isopropyl phenol and crystal, which is applied in the field of continuous separation of isopropyl phenol, can solve the problems of difficult industrial production of isopropyl phenol, difficult separation of isopropyl phenol, low catalyst selectivity, etc. Consumption, save equipment, shorten the effect of purification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

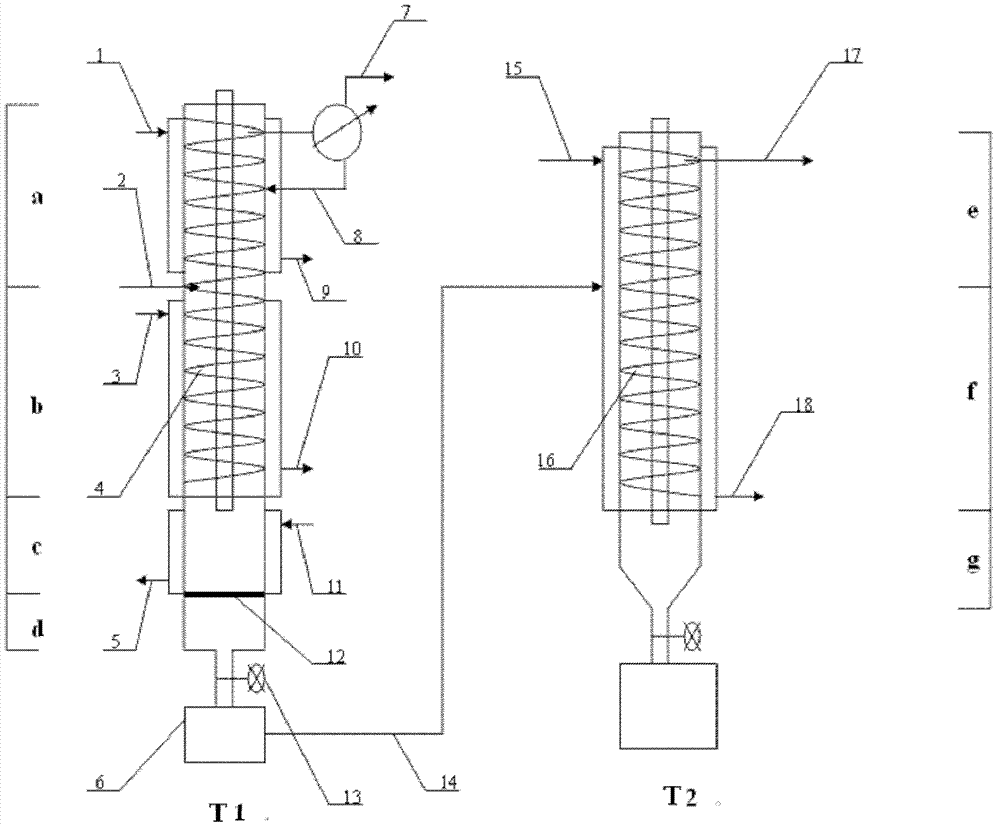

[0037] Such as figure 1 Shown, a device for continuous separation of o-p-isopropylphenol.

[0038] including tower 1 and tower 2 connected in series,

[0039] Rotating scrapers are respectively installed at the axis of the tower body in the tower 1 and the tower 2, the lower part of the tower 1 is provided with a grid, and the outer side of the tower 1 and the tower 2 is provided with a constant temperature feeding port;

[0040] A liquid purification section a, a crystal purification section b, a melting purification section c, and a crystal deposition section d are sequentially arranged in the tower 1 from top to bottom; above the constant temperature feed port 2 of the tower 1 is a liquid purification section a; Between the feed port 2 and the lower end of the rotating scraper is the crystal purification section b; between the lower end of the rotating scraper and the grid sieve is the melting purification section c; between the grid sieve and the bottom of the tower body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com