Multi-arm block copolymer, preparation method and application of multi-arm block copolymer in improvement of mechanical property of poly-L-lactic acid thereof

The technology of a block copolymer and L-polylactic acid is applied in the application field of improving the mechanical properties of L-polylactic acid, which can solve the problems of poor compatibility and inability to effectively improve the mechanical properties, and achieve good transparency and good dispersion behavior. , the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

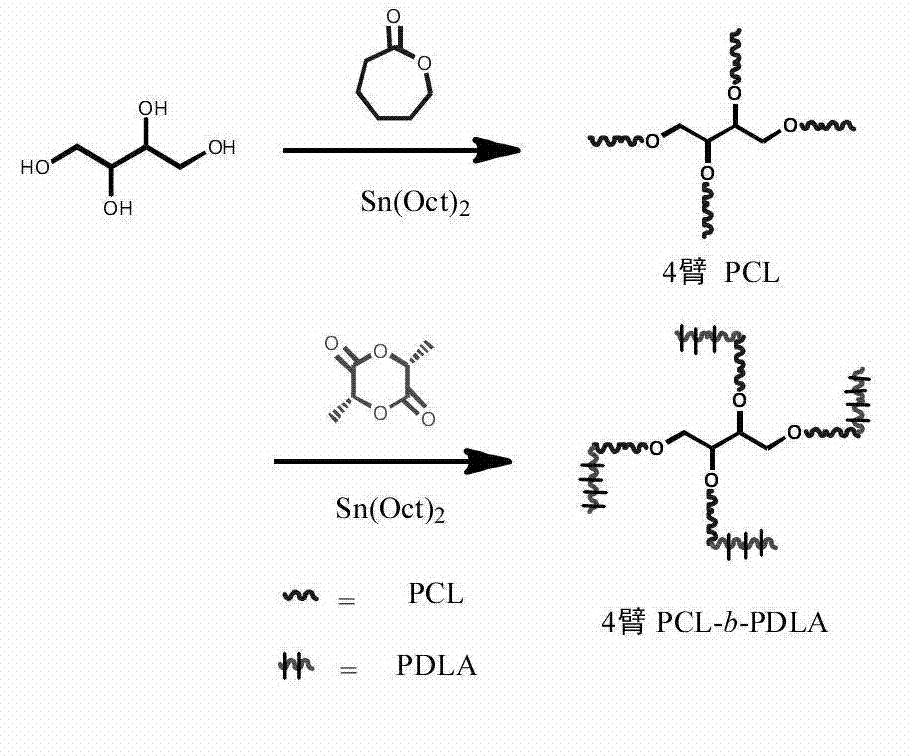

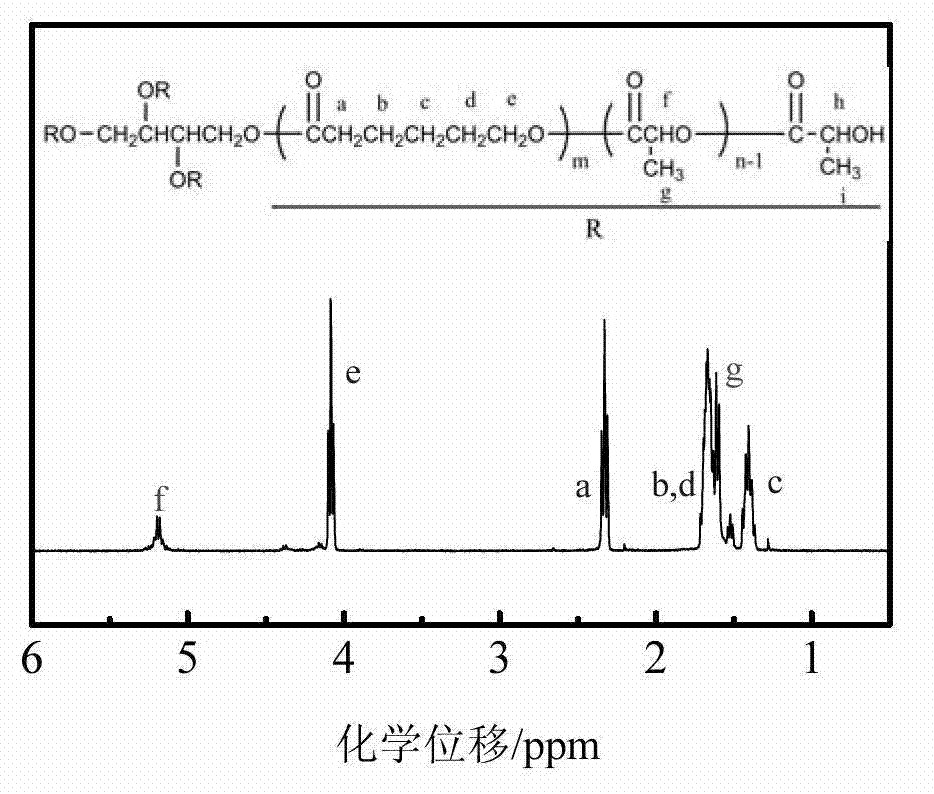

[0046] Embodiment 1: the synthesis of multi-arm block copolymer

[0047] 1) Synthesis of 4a-PCL-b-PDLA

[0048] synthetic circuit such as figure 1 shown. First, the reaction device was evacuated 3 times and protected by argon, and then 8.36g ε-caprolactone, 0.2041g erythritol, 126L of stannous octoate in toluene (0.846mol / L) and 10mL of toluene were placed under argon protection. Add it to the reaction tube, seal it and react at 110°C for two days. Then, the temperature of the reaction tube was lowered to room temperature, and 8.36 g of D-lactide was added into the reaction tube under the protection of argon, and then placed in an oil bath at 110° C. to continue the reaction for 2 to 3 days. After the reaction was completed, it was cooled to room temperature, and the reaction product was repeatedly dissolved / precipitated three times through dichloromethane / methanol (v / v=1 / 10), and finally the product was placed in a vacuum oven at 80°C and vacuum-dried until the quality was...

Embodiment 2

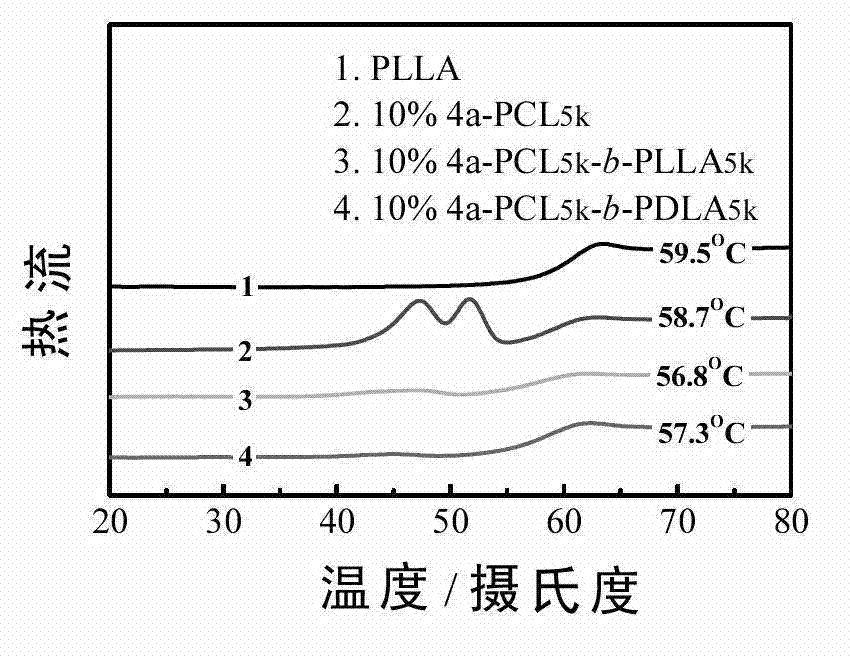

[0055] Embodiment 2: Preparation of multi-arm block copolymer and L-polylactic acid blend (i.e. modified polylactic acid)

[0056] The following takes the blending of the four-arm block copolymer 4a-PCL-b-PDLA prepared in Example 1 and L-PLA as an example. The blending of other multi-arm block copolymers and L-PLA has the same experimental conditions.

[0057] 1) Melt blending

[0058] Weigh 5g of 4a-PCL-b-PDLA and 45g of poly-L-lactic acid (PLLA) (Natureworks, USA, model 2002D) respectively, and process multi-arm block copolymer and poly-L-lactic acid with HAAKE twin-screw internal mixer. Melt blending, the conditions are as follows: the melting temperature of the blend is 170-230° C., the blending speed is 10 rad / min for the first 2 minutes, and 50 rad / min for the last 8 minutes.

[0059] 2) Preparation of splines

[0060] The blend splines were injection molded through a HAAKE MINI JET II with a capacity of 10 cc according to ISO527-2-5A standard. Put the sample obtained...

Embodiment 3

[0063] Embodiment 3: Preparation of multi-arm block copolymer and L-polylactic acid blend (i.e. modified polylactic acid)

[0064] The amount of 4a-PCL-b-PDLA in step 1) of Example 2 was replaced by 2.5g, the amount of L-polylactic acid (PLLA) was replaced by 47.5g, and the other conditions were the same as in Example 2, and a modified polylactic acid sample was prepared. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com