Method for testing film thermal conductivity

A technology of thermal conductivity and thin film, applied in the field of double-end supported cantilever beam structure and its testing field, can solve the problems of difficult structural processing, unfavorable extraction of parameters to be measured, complex temperature rise expression of test structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

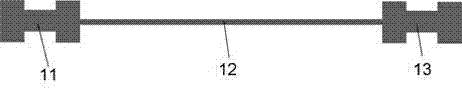

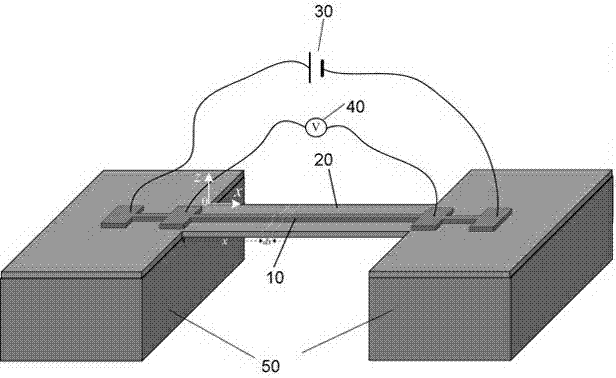

[0055] see figure 1 , figure 2 , for the test structure model, the test structure is a double-ended support cantilever beam, the cantilever beam is composed of an upper narrow and long metal resistance strip 10, a lower film to be tested 20 and support blocks 50 at both ends of the lower surface of the film to be tested 20, the metal The resistance bar 10 is also used as a heating resistor and a temperature measuring resistor, and the double-ended support cantilever beam structure is prepared by surface micromachining technology, and the support block 50 is a silicon chip or a sacrificial layer material, such as polyimide or silicon dioxide, The length of the cantilever beam (such as 200 μm) is ten times greater than the width (such as 8-20 μm) so that the length is much greater than the width so that the heat conduction problem of the struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com