Steel-belt-type detection device for evaluation of microwave flatness

A microwave plane, microwave detection technology, applied in the direction of electromagnetic field characteristics, etc., can solve the problems of increasing the complexity and uncertainty of installation and debugging of the system, large radar cross section scattering value, equipment transportation problems, etc., to simplify the difficulty of installation and debugging, The effect of reducing cross-section scattering value and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

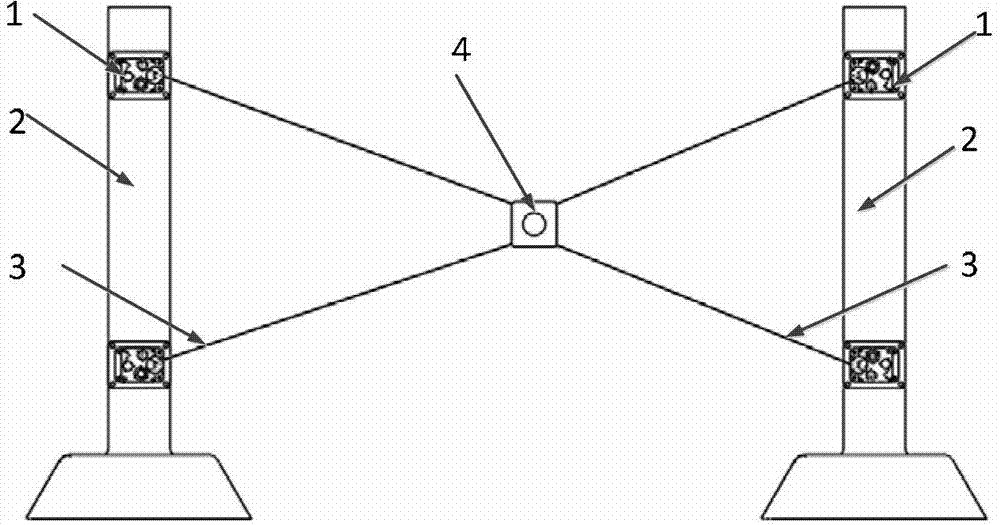

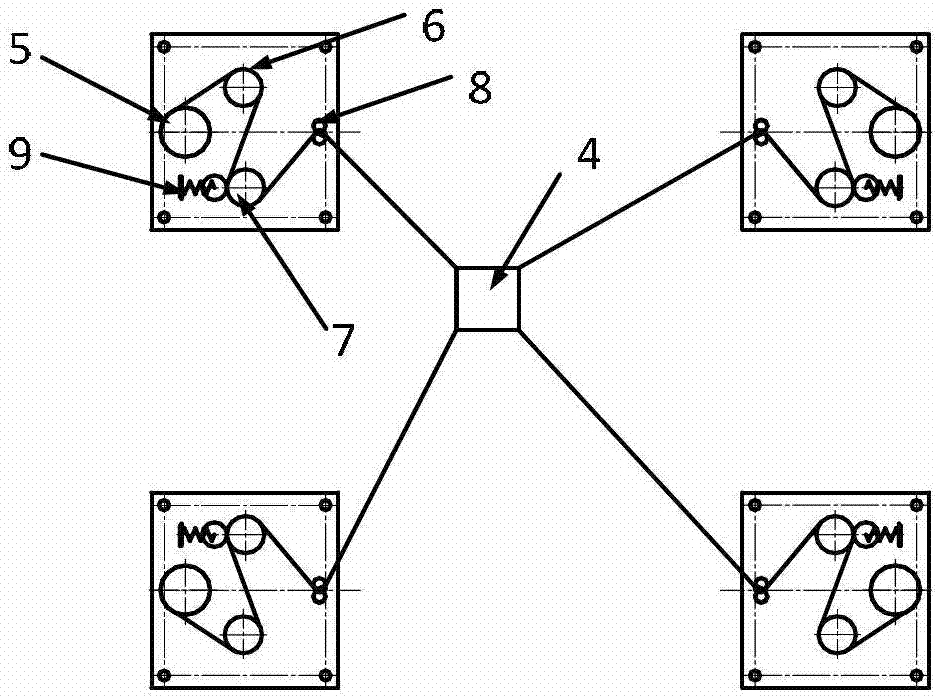

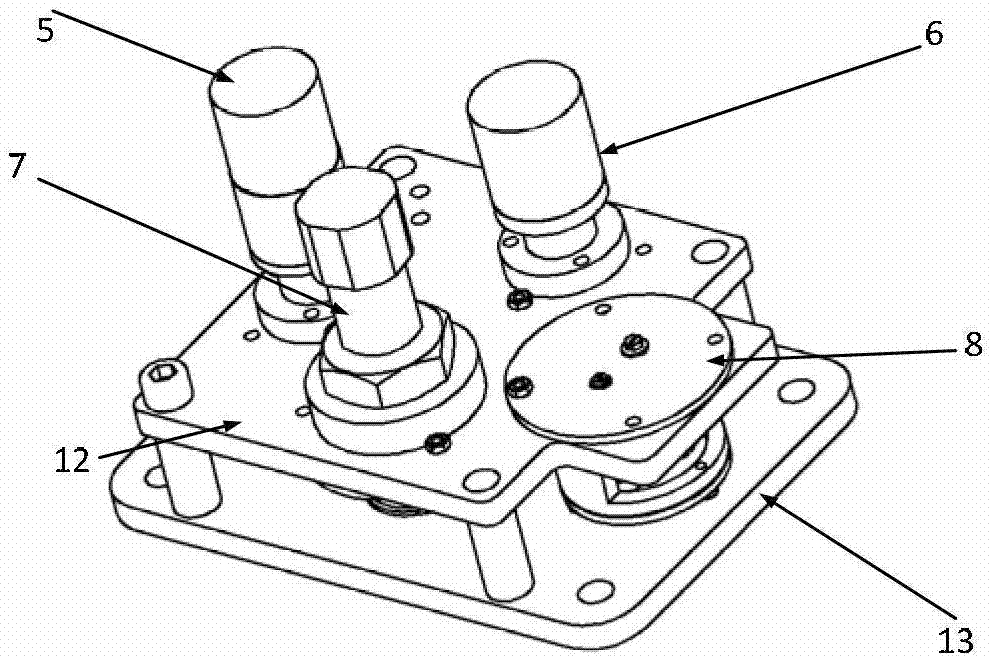

[0053] During the working process of the microwave flatness detection device of the present invention, the microwave detection platform 4 is always point-controlled to ensure that the microwave detection platform 4 does not rotate around its own center, and the rotation angle of the microwave measurement sensor 81 is completely controlled by the platform. DC motor 84 to control. Point A on its static platform 1 、A 2 、A 3 、A 4 It constitutes a vertical plane, which coincides with the coordinate plane XOY of the fixed coordinate system. The moving platform is composed of four steel belts A 1 B 1 、A 2 B 2 、A 3 B 3 、A 4 B 4 Traction, movement in this vertical plane. Point P(x,y,Φ) is not only the center of the moving platform but also its center of mass, x and y are the position of P in the absolute coordinate system, Φ is the angle between the moving platform and the horizontal plane, and the edge of the platform is parallel to the coordinate axis of the reference syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com