Abnormity determining method for battery pack and battery pack thereof

A technology for abnormal determination and battery assembly, which is applied in battery circuit devices, secondary battery repair/maintenance, measurement of electricity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

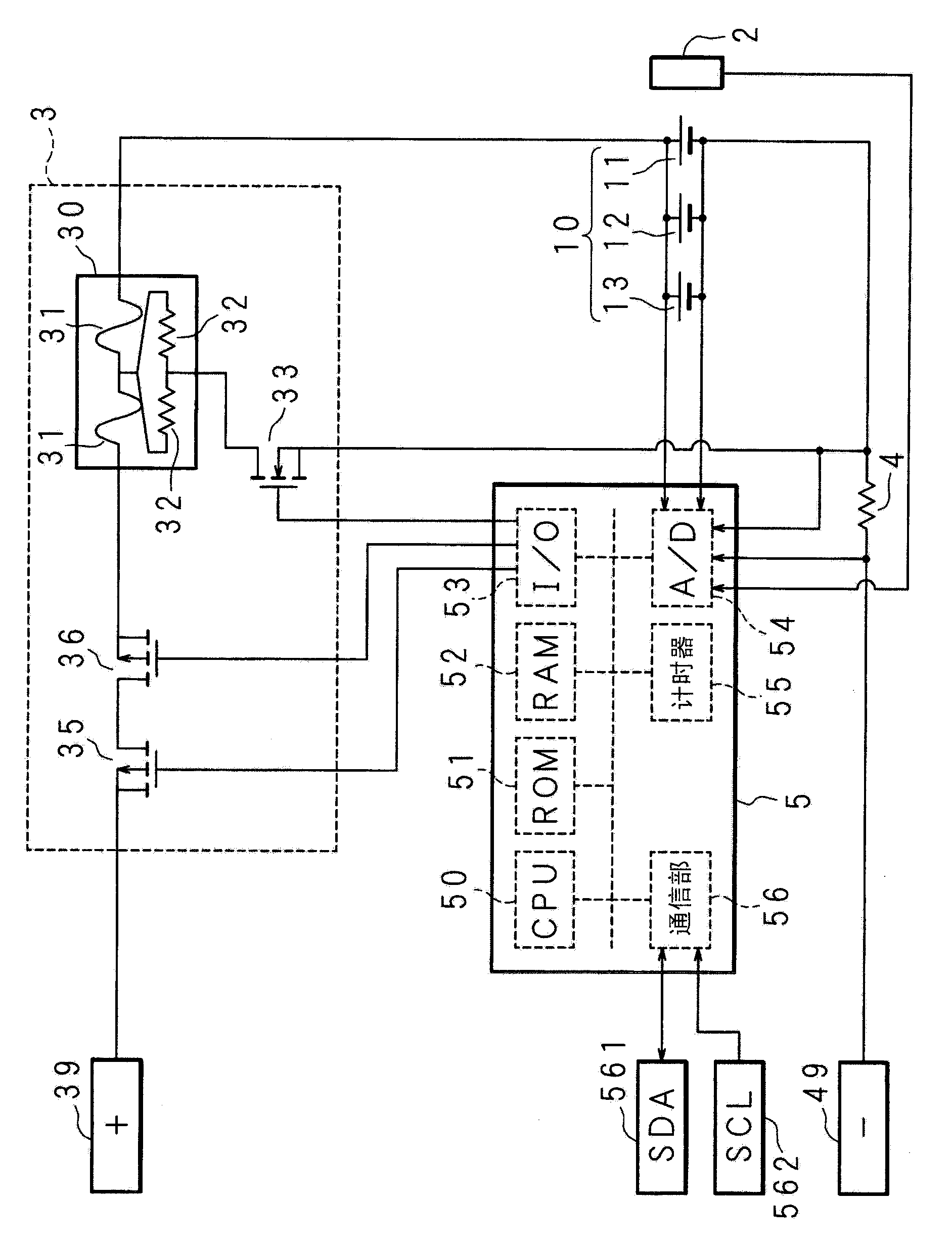

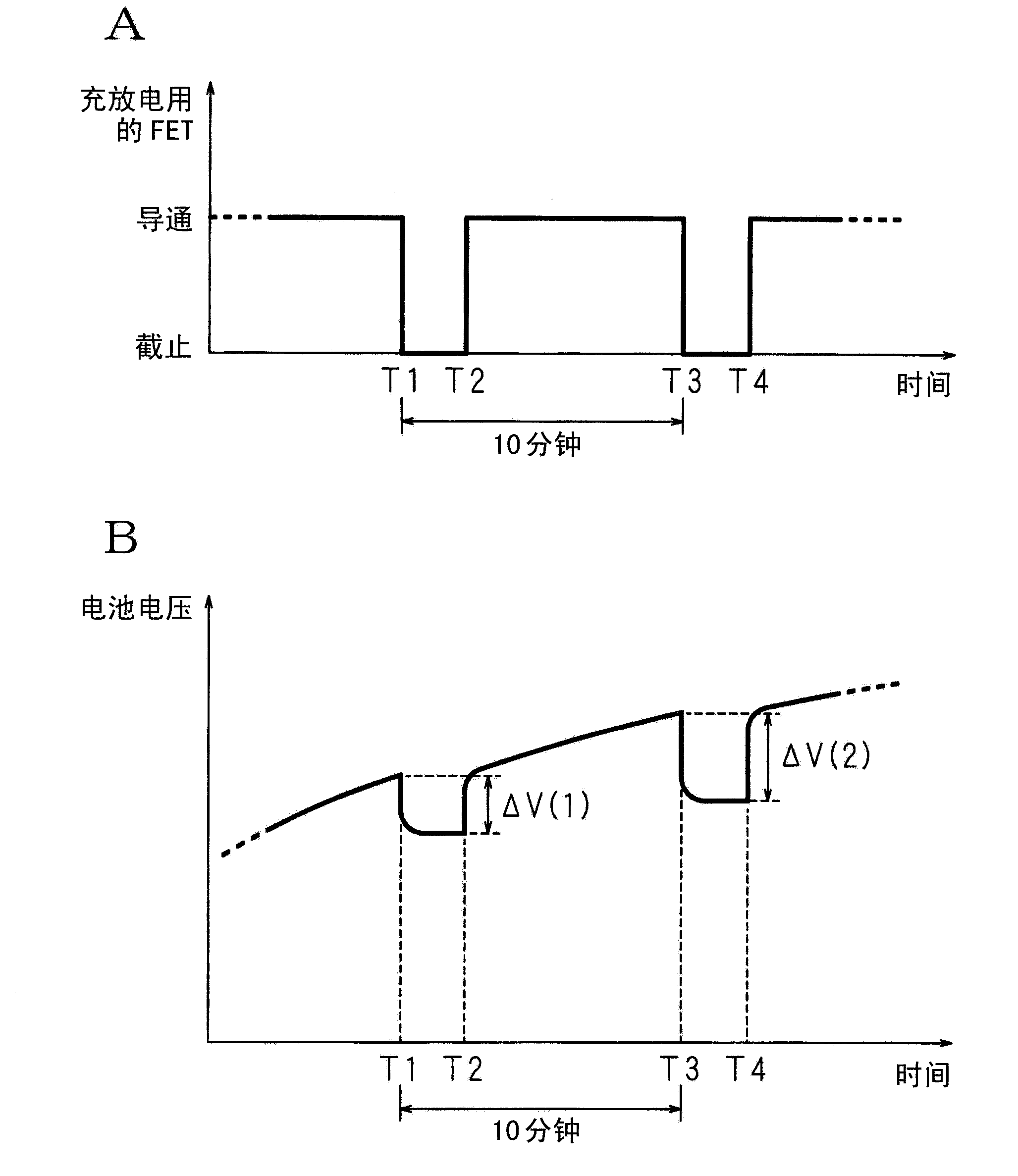

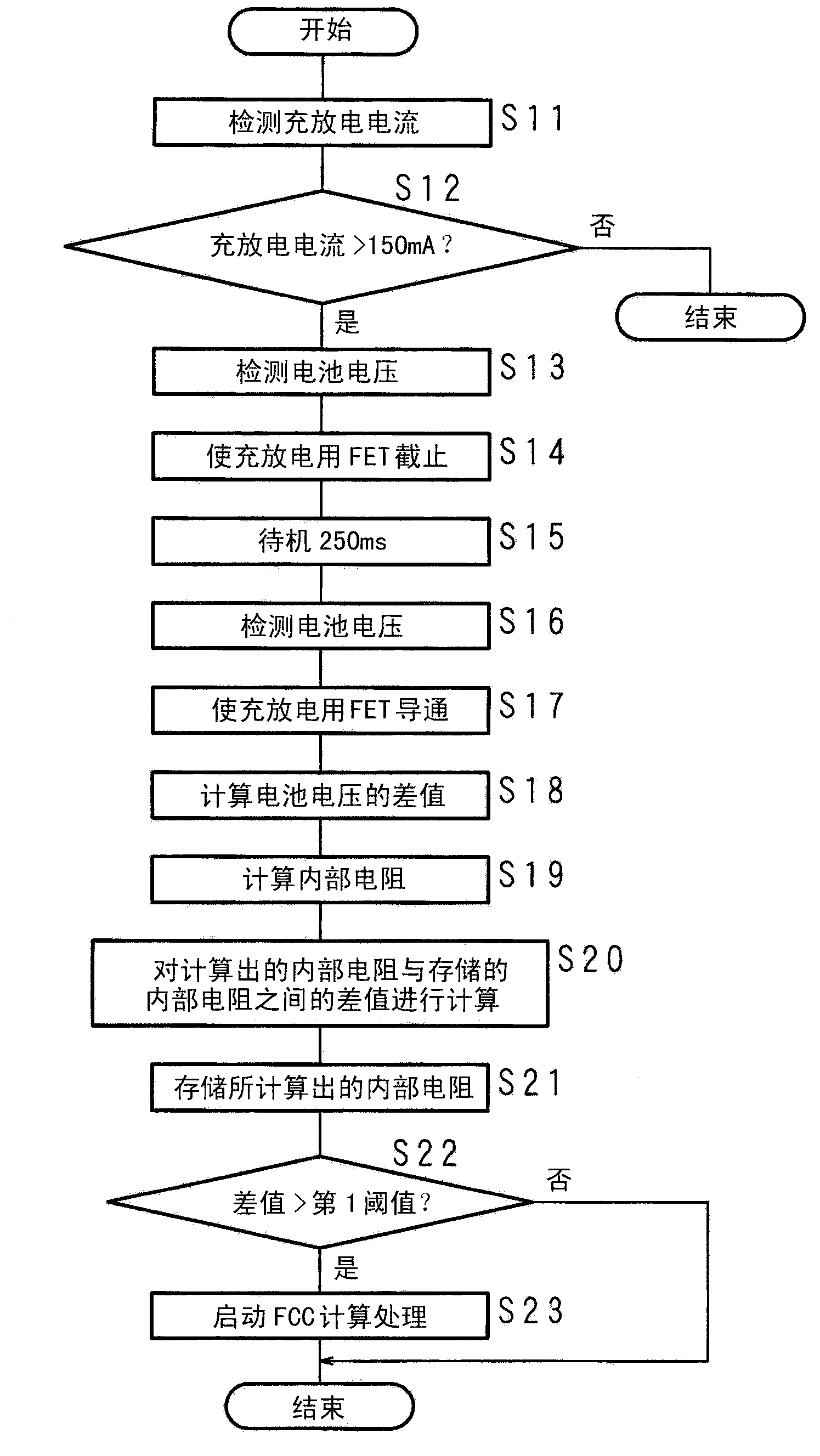

[0045] figure 1 It is a block diagram showing a configuration example of the assembled battery according to the present invention. In the figure, 10 is a battery block, and the battery block 10 is formed by connecting secondary batteries 11, 12, and 13 composed of lithium ion batteries in parallel with a conductive connector not shown. In the vicinity of the battery block 10, a temperature sensor 2 for detecting the temperature of the battery block 10 is arranged. The secondary batteries 11, 12, and 13 may be other batteries such as nickel-hydrogen batteries and nickel-cadmium batteries. In addition, the number of secondary batteries constituting the battery block 10 is not limited to three, and may be two or four or more.

[0046] The positive terminals of the secondary batteries 11, 12, and 13 are connected to the positive (+) terminal 39 via a cutoff portion 3 for cutting off the charge and discharge current of the secondary batteries 11, 12, and 13. The negative terminals o...

Embodiment approach 2

[0088] In the first embodiment, an abnormality related to the parallel capacity of the secondary batteries 11, 12, and 13 is determined. In contrast, in the second embodiment, an abnormality related to the battery voltage of the secondary batteries 11, 12, and 13 is determined.

[0089] For example, in the secondary batteries 11, 12, and 13, signs of a local short circuit between the electrodes (positive and negative electrodes) are found in the interior of the secondary battery 13, but even if it is left alone, the electrodes may The short-circuit between time develops and causes accidents such as fire and rupture of the assembled battery.

[0090] Therefore, in the second embodiment, for the battery voltages of the secondary batteries 11, 12, and 13 detected in time series during the period when neither charging nor discharging is performed, the newly detected battery voltage is compared with the previous detected battery voltage. When the battery voltage is lower than the voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com