Tunable array waveguide grating based on liquid crystal waveguides

An arrayed waveguide grating and arrayed waveguide technology, which is applied in the directions of light guides, optics, optical components, etc., can solve the problems of high cost, poor performance consistency, complicated preparation process of tunable arrayed waveguide gratings, etc., and achieves good performance consistency and simple structure. , to achieve the effect of tunable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

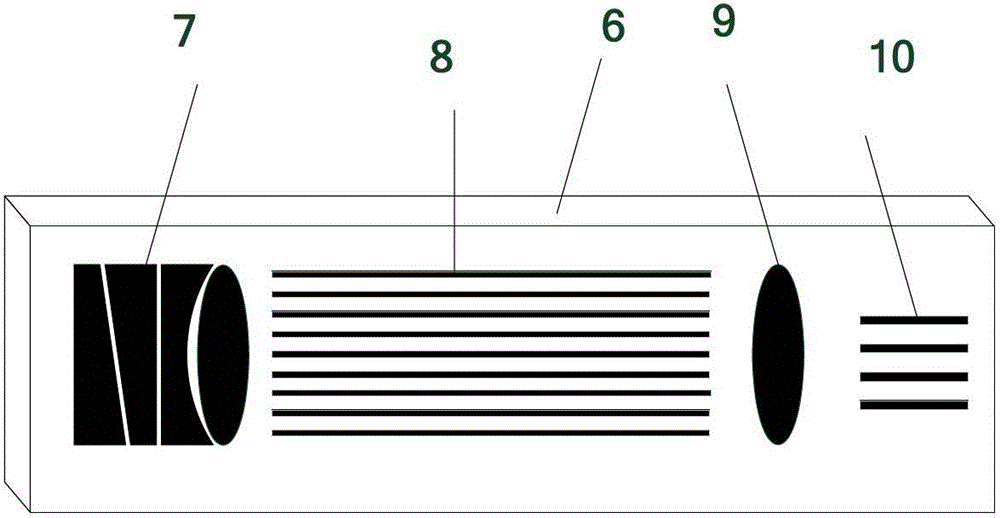

[0040] The gap between each part of the input coupling region 7 , the arrayed waveguide region 8 , the output coupling region 9 and the output waveguide region 10 is 300 μm;

[0041] The first right-angled trapezoidal prism-shaped electrode 7-1 and the second right-angled trapezoidal prism-shaped electrode 7-2 have an upper side length of 100 μm, a length ratio of the upper and lower sides of 1:4, and a height of 2000 μm.

[0042] The concave lens-shaped electrode 7-3 has an upper and lower side length of 400 μm, a height of 2000 μm, and a focal length of 500 μm.

[0043] The first convex lens shape electrode 7-4, height 2000μm, focal length 500μm,

[0044] The gap between the first right-angled trapezoidal prism-shaped electrode 7-1, the second right-angled trapezoidal prism-shaped electrode 7-2, the concave lens-shaped electrode 7-3 and the first convex lens-shaped electrode 7-4 is 20 μm;

[0045] The arrayed waveguide region 8 is composed of 80 parallel straight electrodes...

Embodiment 2

[0051] The gap between each part of the input coupling region 7 , the arrayed waveguide region 8 , the output coupling region 9 and the output waveguide region 10 is 50 μm;

[0052] The first right-angled trapezoidal prism-shaped electrode 7-1 and the second right-angled trapezoidal prism-shaped electrode 7-2 have an upper side length of 10 μm, a length ratio of the upper and lower sides of 1:2, and a height of 50 μm.

[0053] The concave lens-shaped electrode 7-3 has an upper and lower side length of 20 μm, a height of 50 μm, and a focal length of 100 μm.

[0054] The first convex lens-shaped electrode 7-4, height 50μm, focal length 100μm,

[0055] The gap between the first right-angled trapezoidal prism-shaped electrode 7-1, the second right-angled trapezoidal prism-shaped electrode 7-2, the concave lens-shaped electrode 7-3 and the first convex lens-shaped electrode 7-4 is 5 μm;

[0056] The arrayed waveguide region 8 is composed of 10 parallel straight electrodes, each of...

Embodiment 3

[0062] The gap between each part of the input coupling region 7 , the arrayed waveguide region 8 , the output coupling region 9 and the output waveguide region 10 is 100 μm;

[0063] The first right-angled trapezoidal prism-shaped electrode 7-1 and the second right-angled trapezoidal prism-shaped electrode 7-2 have an upper side length of 50 μm, a length ratio of the upper and lower sides of 1:3, and a height of 1000 μm.

[0064] The concave lens-shaped electrode 7-3 has an upper and lower side length of 150 μm, a height of 1000 μm, and a focal length of 100.

[0065] The first convex lens shape electrode 7-4, height 1000μm, focal length 100μm,

[0066] The gap between the first right-angled trapezoidal prism-shaped electrode 7-1, the second right-angled trapezoidal prism-shaped electrode 7-2, the concave lens-shaped electrode 7-3 and the first convex lens-shaped electrode 7-4 is 10 μm;

[0067] The arrayed waveguide region 8 is composed of 50 parallel straight electrodes, ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com