Amorphous alloy transformer and iron core thereof and manufacturing method thereof

A technology of amorphous alloy and manufacturing method, applied in the field of transformers, can solve the problems such as noise of amorphous alloy transformers, and achieve the effects of enhancing overall rigidity, enhancing reliability and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose and features of the present invention more comprehensible, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

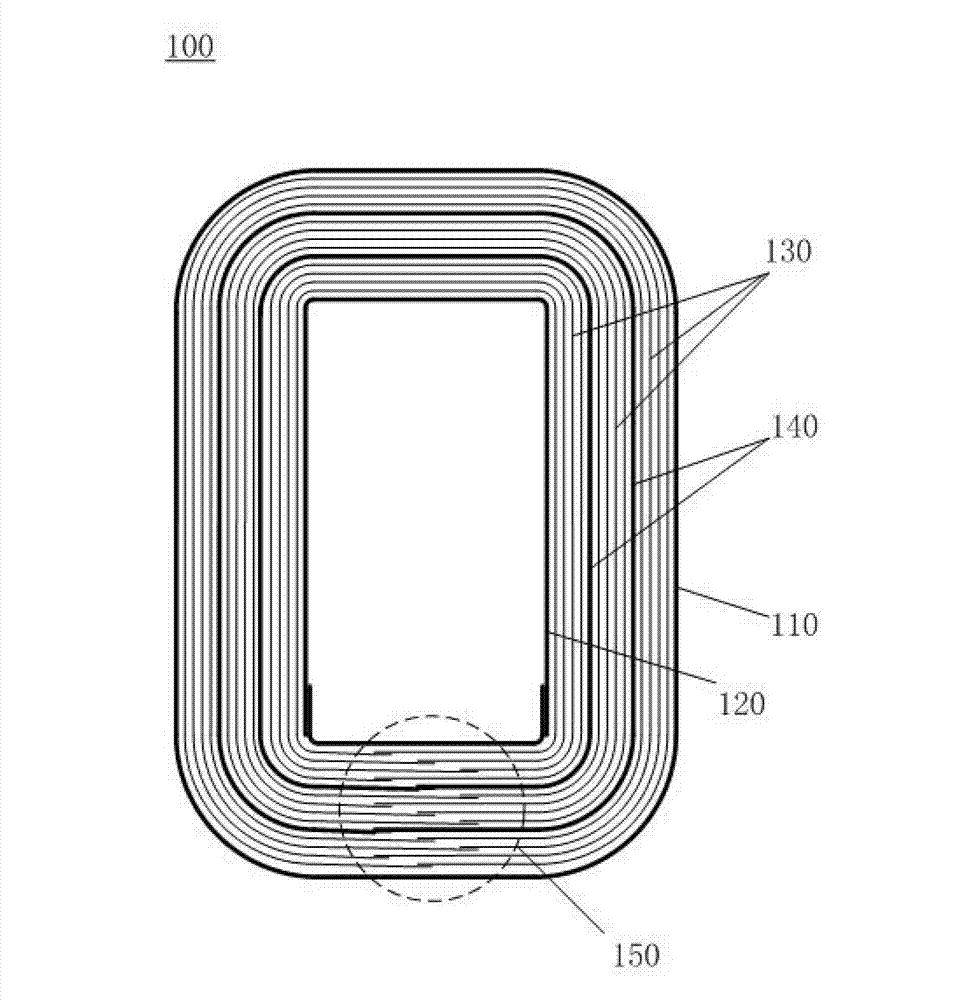

[0023] See figure 1 , which is a schematic structural view of an amorphous alloy iron core provided by an embodiment of the present invention. As shown in the figure, the amorphous alloy iron core 100 includes an outer template 110 , an inner template 120 , and multiple stacks of amorphous alloy sheets 130 disposed between the inner template 120 and the outer template 110 . Wherein, the multiple stacks of amorphous alloy sheets 130 are separated by support sheets 140 , that is, support sheets 140 are provided between every two adjacent sets of amorphous alloy sheets.

[0024] In the above embodiments, a support sheet with a supporting function is placed in the amorphous alloy sheet, so that the external force resistance of the amorphous alloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com