Method for Removing Emitter Polysilicon Etching Residue in Bipolar Transistor Process

A technology of bipolar transistors and etching residues, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of emitter polysilicon etching residues, etc., to solve etching residues, shorten distances, reduce The effect of the risk of electric leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

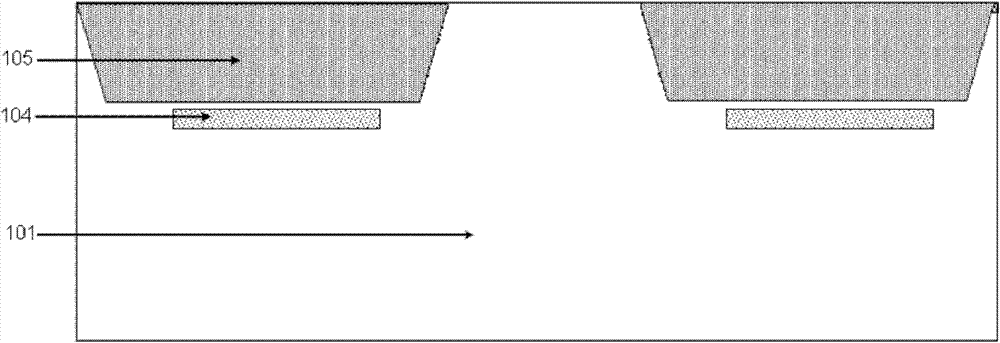

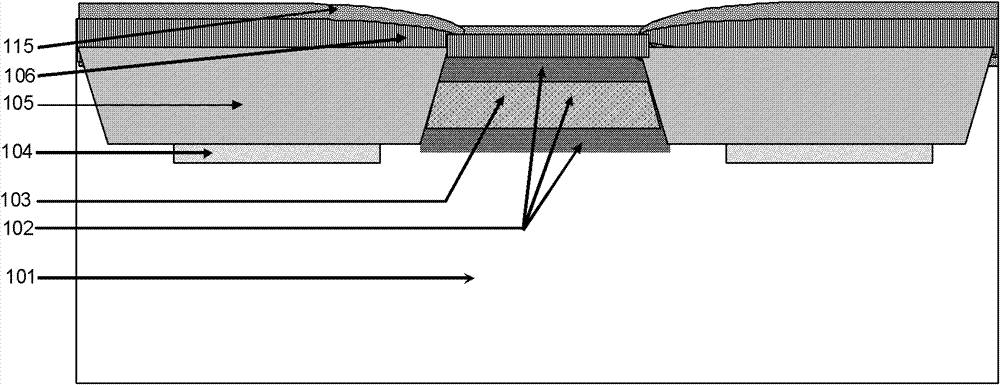

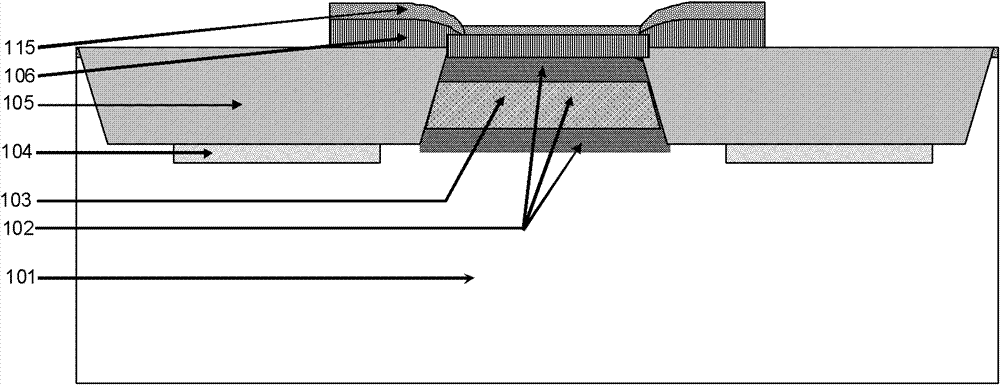

[0024] The bipolar transistor structure produced by the method for removing the emitter polysilicon etching residue in the bipolar transistor process in the present invention is as follows Figure 6 As shown, the active region consists of shallow trench field oxygen ie figure 1 The shallow trench isolation layer 105 in isolation includes a collector region, a pseudo-buried layer, a base region and an emitter region.

[0025] Such as Figure 1 to Figure 6 Shown is a schematic diagram of the device structure during the manufacturing process of the embodiment of the present invention. The method of the embodiment of the present invention comprises the following steps:

[0026] In step 1, a shallow trench isolation layer 105 is formed on the P-type silicon substrate 101, and a dose of 10 is implanted at the bottom of the shallow trench isolation layer 105. 15 ~10 16 cm -2 N-type ions with an energy of 5-15keV form the N-type pseudo-buried layer 104, and the implanted ions ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com