Frequency converter used for electric discharge machining linear cutting machine

A technology of electric discharge wire and cutting machine tools, which is applied in the field of frequency converters, can solve the problems of increased maintenance personnel, unstable performance, and difficulty, and achieve the effects of overcoming poor insulation, reliable functions, and reducing maintenance costs and difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

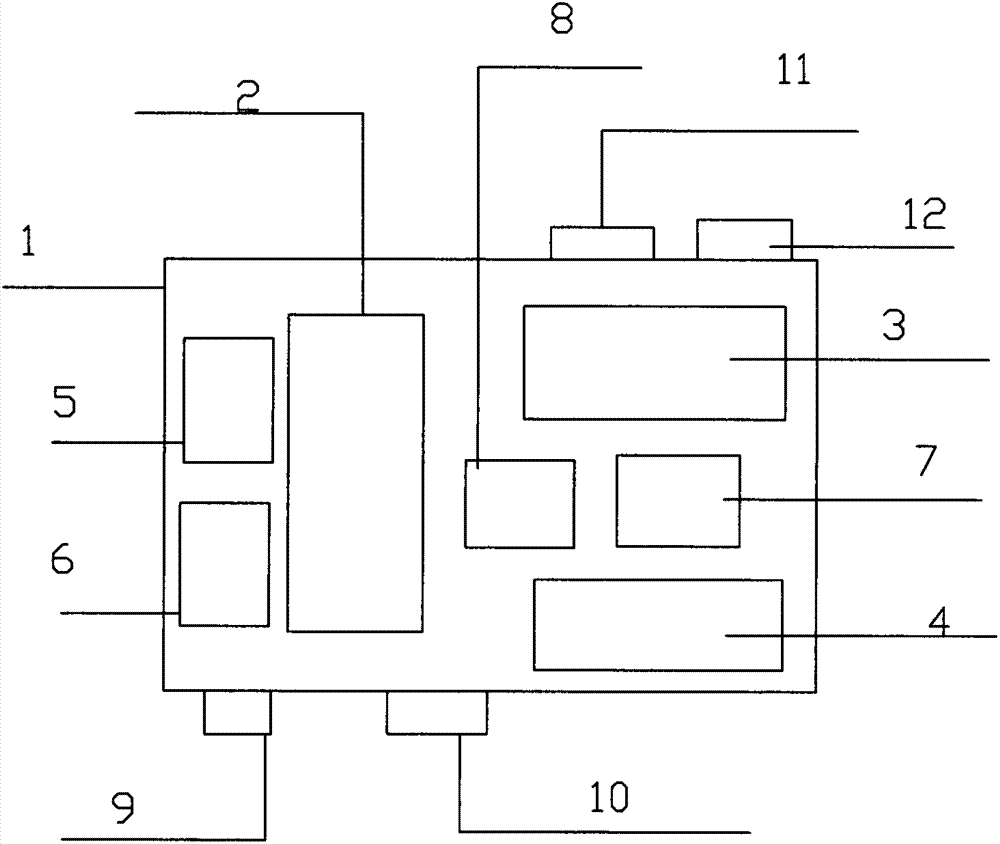

[0015] see figure 1 , Divide the inverter into three independent parts: power module, 2, control module 3, and frequency conversion module 4. The control module 3 is externally connected to the input signal through the connector DB15 and DB25 socket, and the frequency conversion output is connected to the wire conveying, the water pump motor and the lighting lamp through the 12-core aviation socket.

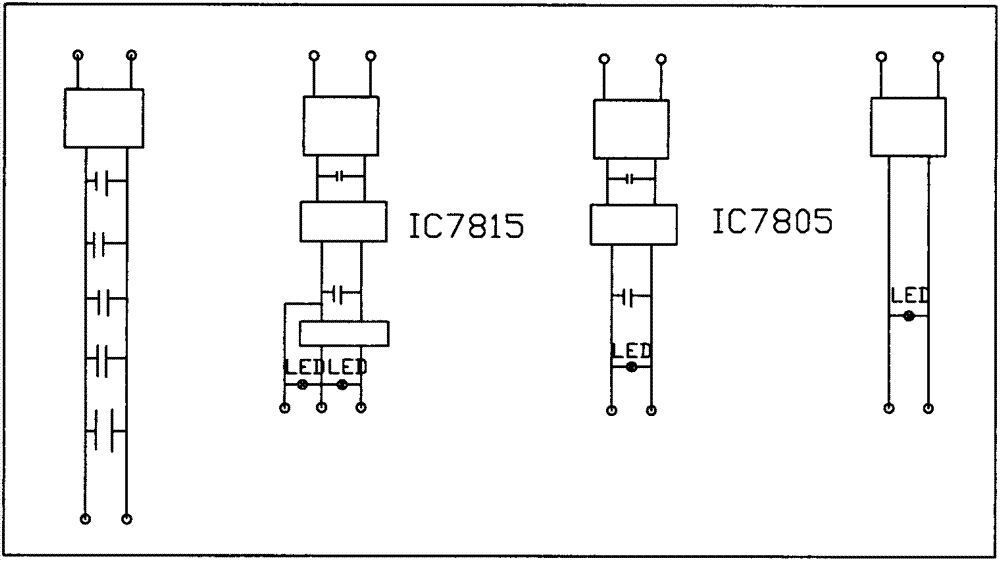

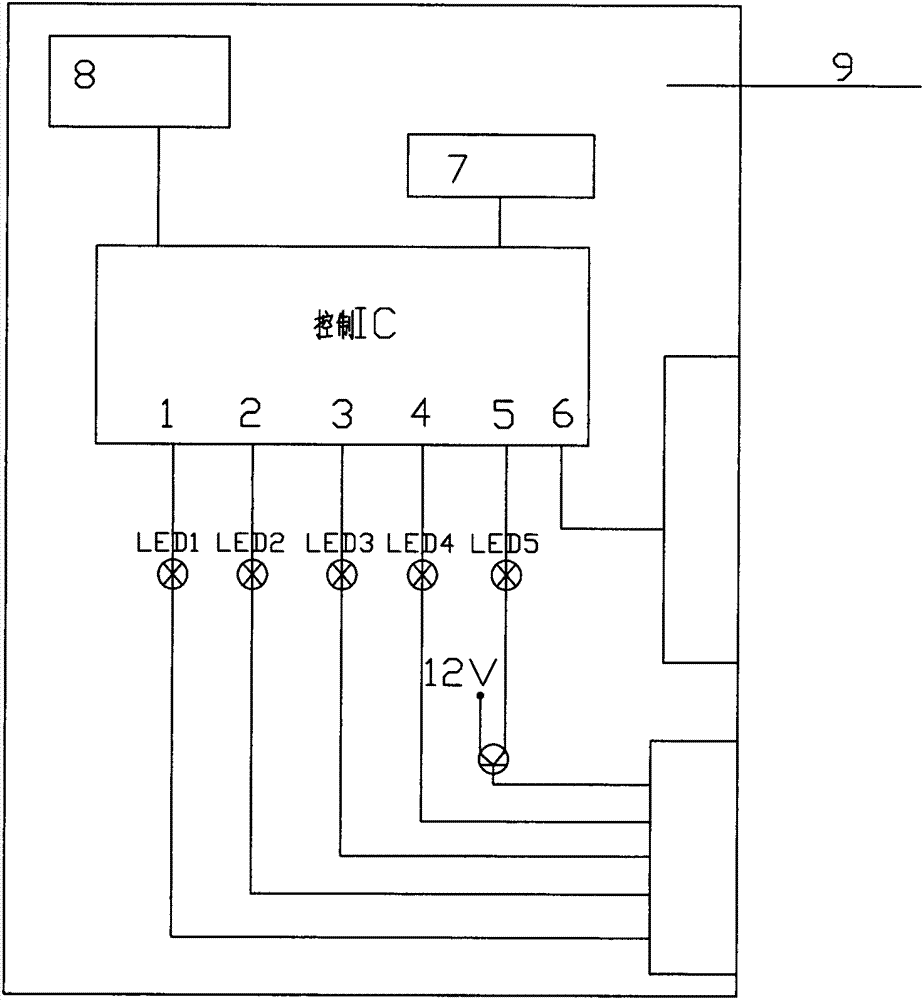

[0016] see figure 2 , In the power supply module, LED displays are added corresponding to each power supply to indicate the working status of each power supply. figure 2 The schematic diagrams of adding LEDs to the bus voltage of the frequency conversion module, the working voltage of the frequency conversion module, the working voltage of the control module and the control loop voltage of the control module are respectively shown. see image 3 , LED lights are connected in series in each control loop to monitor the operation of each control point in real time. Therefore, n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com