A device that uses two-stage cooling to solve the problem of antifreeze corrosion of silicon rectifier components

A technology of silicon rectifiers and coolers, which is applied in the direction of output power conversion devices, electrical components, cooling/ventilation/heating transformation, etc., and can solve problems such as pipeline leakage, rectifier insulation damage, rectifier component cooling circulation pipeline corrosion, etc. Achieve the effects of reducing loss, ensuring quality, and preventing antifreeze from corroding rectifier components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

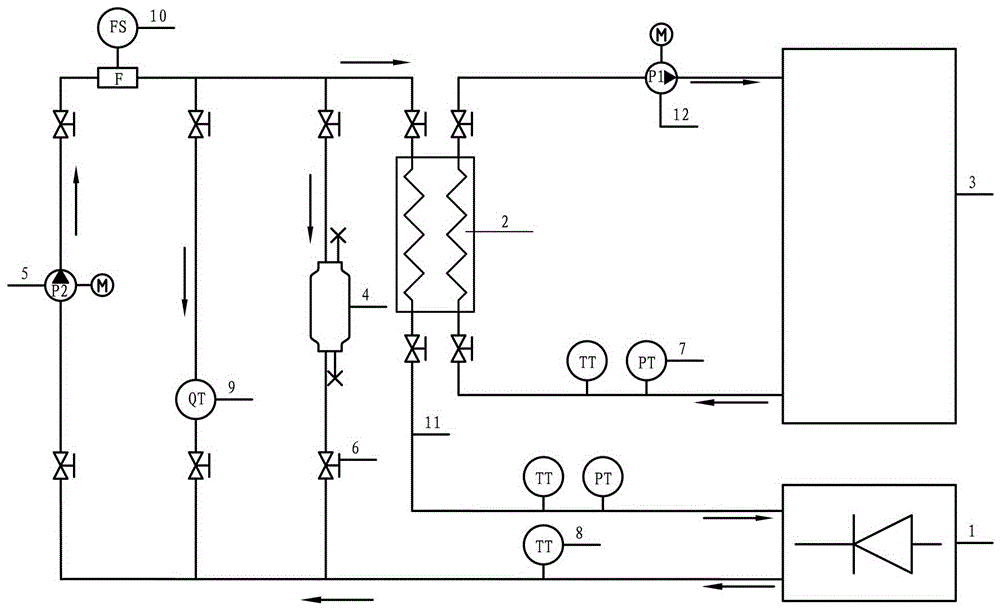

[0021] as attached figure 1 The device shown in the present invention adopts two-stage cooling to solve the problem of antifreeze corrosion of silicon rectifier elements, including a rectifier element primary cooler 1, the return pipe of the rectifier element primary cooler 1 is connected to one end of the first water pump 5, and the first water pump 5 The other end is connected to the water inlet pipe 11, and the water inlet pipe 11 passes through the plate heat exchanger 2 for heat exchange. Both ends of the heat exchange pipeline of the plate heat exchanger 2 are connected to the water air cooler 3, and the water air cooler 3 is located outdoors .

[0022] A flow sensor 10 is provided between the first water pump 5 and the plate heat exchanger 2, a valve 6 is provided on the pipeline on both sides of the first water pump 5, and a valve 6 is provided on both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com