Stepless speed regulation driver for diesel locomotive

A technology of stepless speed regulation and diesel locomotive, which is applied in the direction of motor generator control, electrical components, control system, etc. It can solve the problems of many application IC integrated blocks, easy electrostatic breakdown, and high failure probability, and achieve simplified circuit and integration. The effect of machine power consumption, voltage stability, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

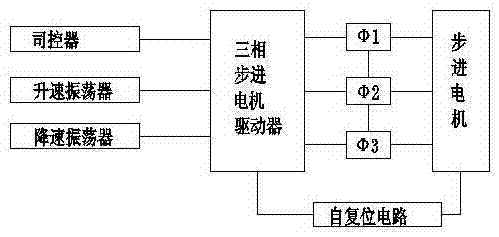

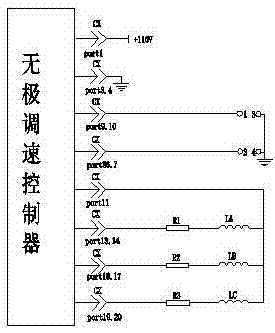

[0016] Such as figure 1 It is a schematic diagram of the structure principle of the present invention, a stepless speed regulation driver for a diesel locomotive, including a controller, a speed-up oscillator, a speed-down oscillator, a three-phase stepping motor driver U3 and a reset circuit, a controller, a speed-up Both the high-speed oscillator and the low-speed oscillator are connected to the three-phase stepping motor driver U3, the Ф1, Ф2 and Ф3 three-phase output terminals of the three-phase stepping motor driver U3 are connected to the negative terminal of the stepping motor, and the positive terminal is connected to the stepping motor The common terminal is connected, and a reset circuit is provided in the three-phase stepping motor driver U3.

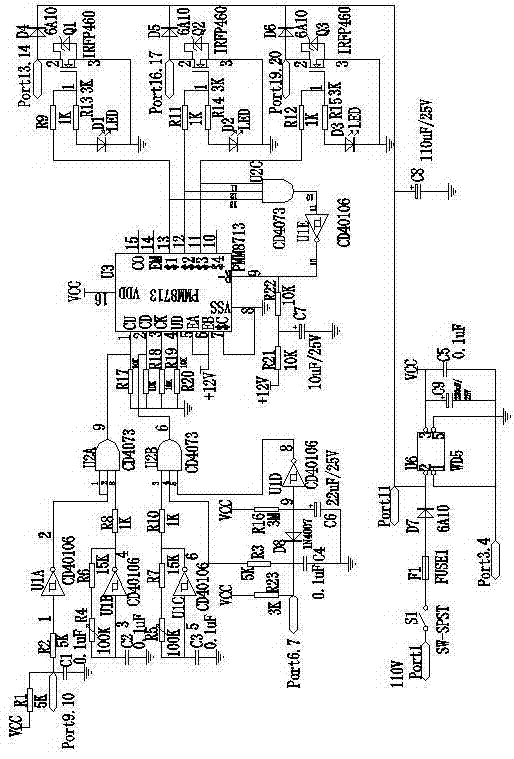

[0017] Such as figure 2 It is the circuit diagram of the present invention, the 3 pins of the driver plug JP1 are connected in series with the pull-up resistor R23, the 4 pins are connected in series with the pull-up resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com