GM motor coaxial/ low pitch sounder loudspeaker device and manufacturing method thereof

A general-purpose automobile and loudspeaker technology, which is applied to vehicle parts, transportation and packaging, and transducer housings/cabinets/brackets, etc. It can solve problems such as noise, low mechanical strength, and increased vehicle weight, so as to ensure electrical safety and facilitate installation Fast and reduce installation man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

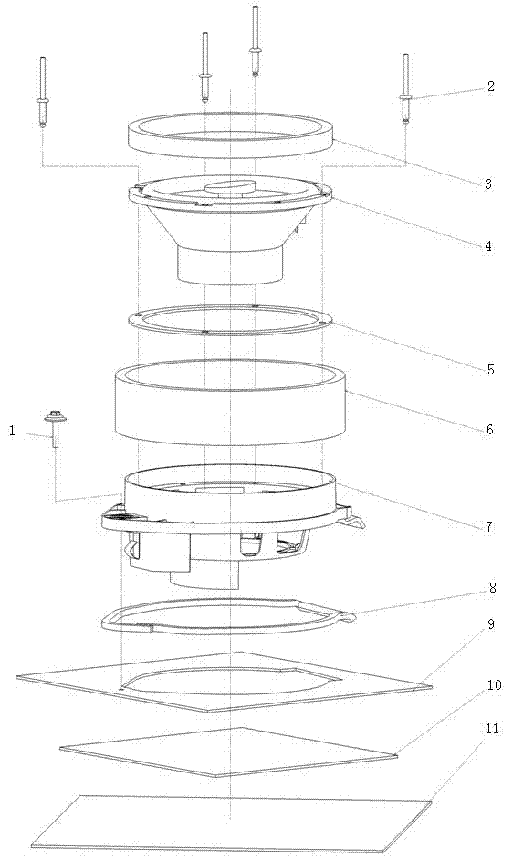

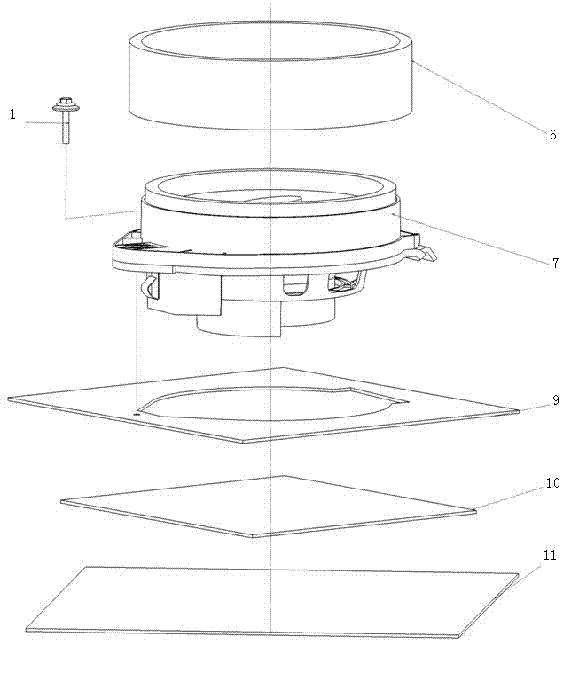

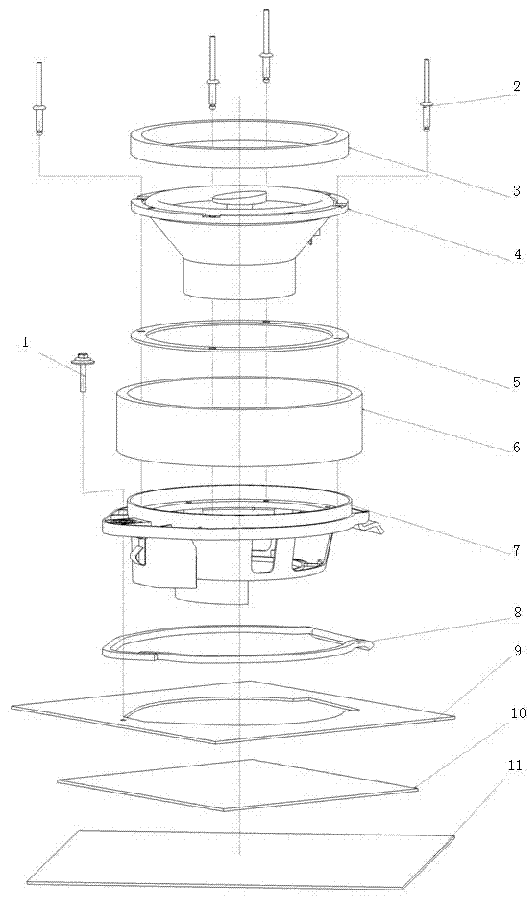

[0035] Please refer to the accompanying drawings for a further description of the present invention.

[0036] Such as figure 1 Shown, the present invention provides a kind of GM general-purpose automobile coaxial / bass audio loudspeaker device, place an annular gasket 5 and loudspeaker 4 in the upper boss of a loudspeaker support 7, be fixed on the inboard of support 7 with rivet 2, in A mounting screw hole is provided on the outer edge of the bracket 7, and the mounting screw hole corresponds to the fixing hole of the body sheet metal parts.

[0037] The top of described loudspeaker 4 is covered with sponge washer 3; The bottom of loudspeaker support 7 is covered with a sealing ring 8; The periphery of boss on loudspeaker support 7 is covered with sponge ring 6 to improve sound quality.

[0038] Described loudspeaker bracket 7 is provided with the electrical connection plug-in of loudspeaker, is connected with the original car loudspeaker signal output end plug.

[0039] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com