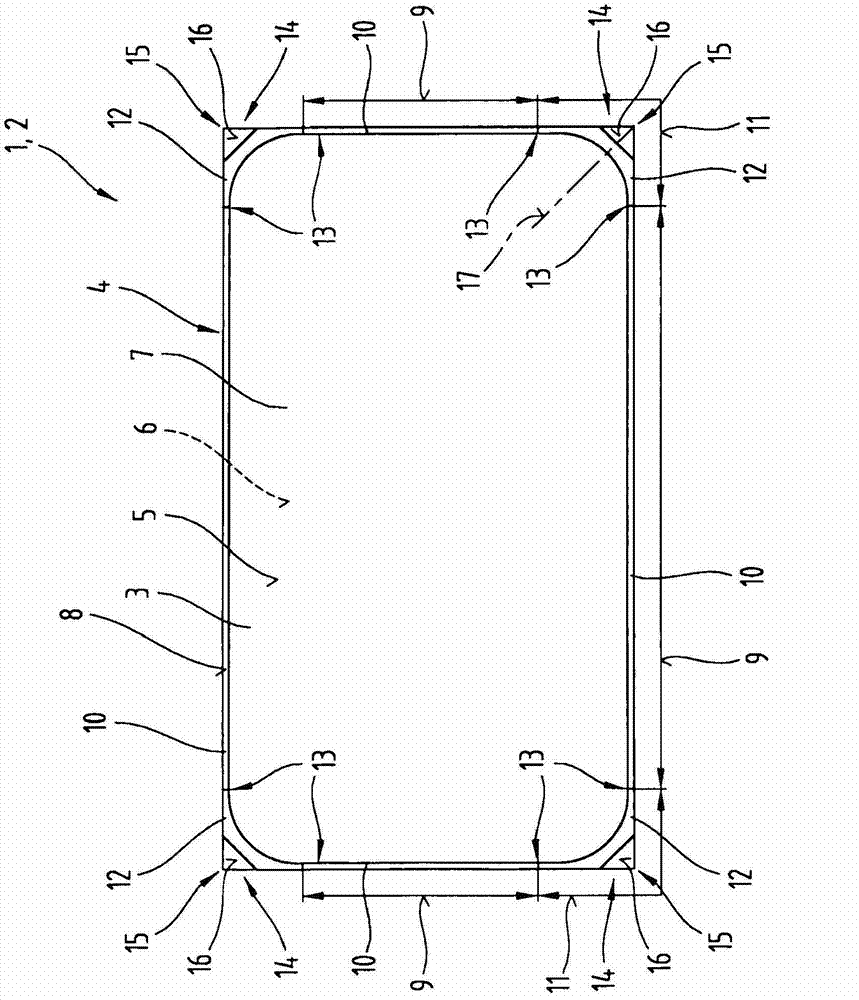

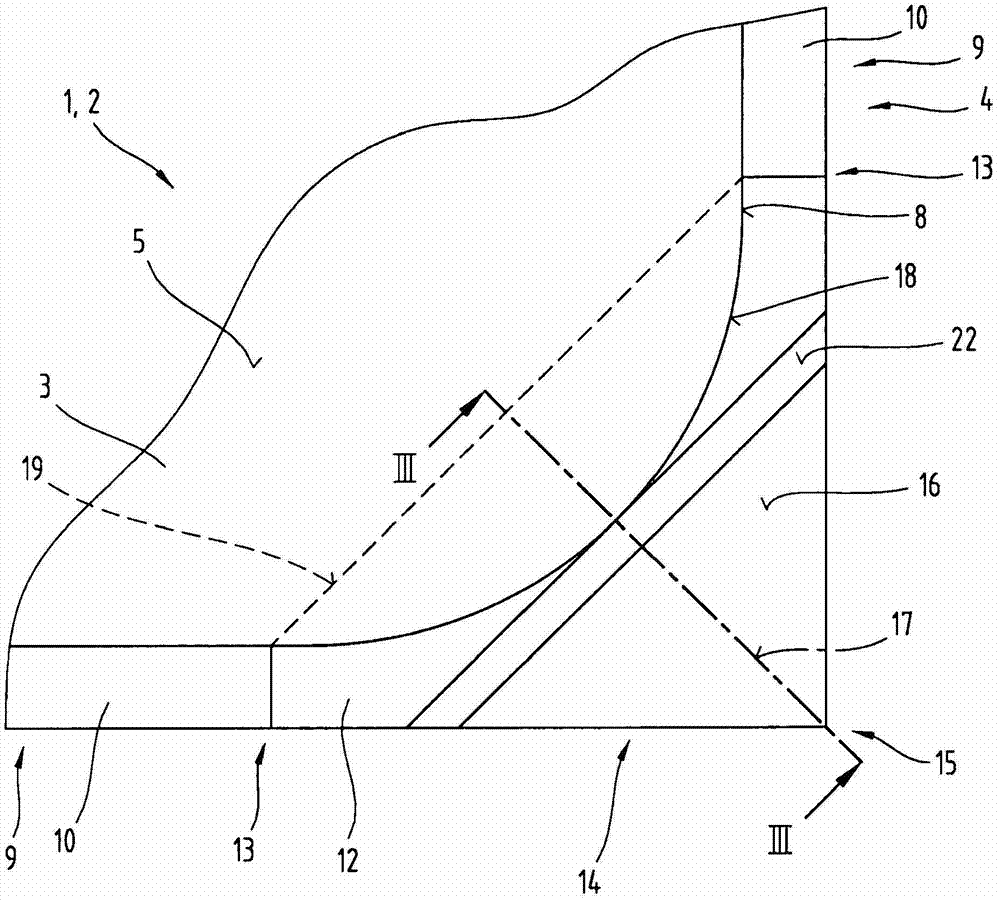

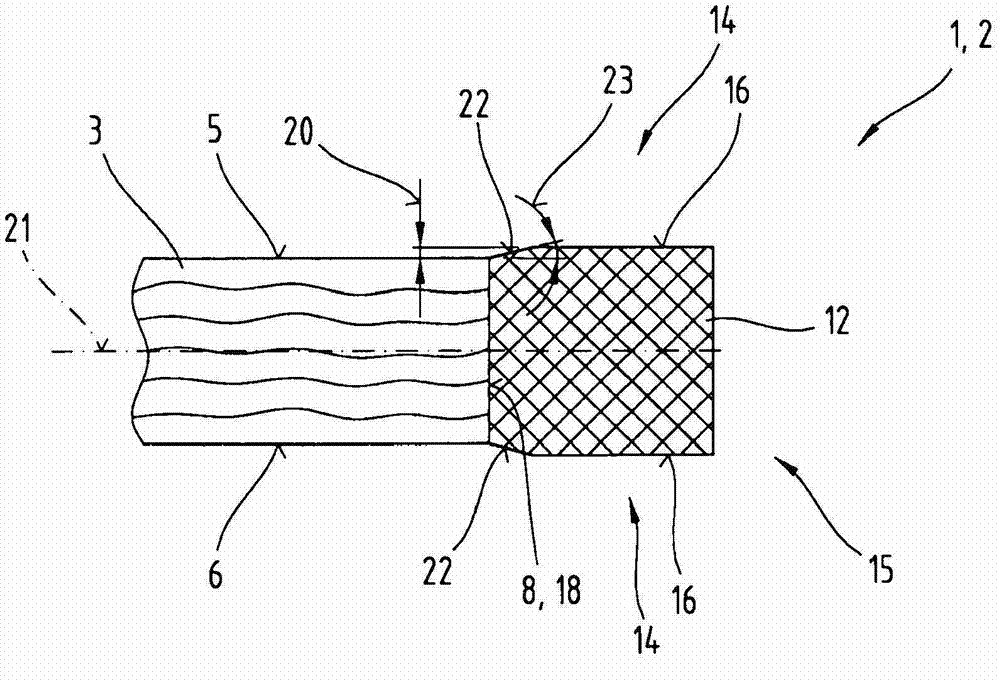

Formwork element having edge protection and method for producing same

A template and component technology, applied in the field of template components, can solve the problems of shortening the service life of template components, negative surface quality, and accelerating the mechanical bearing capacity of template components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] At the outset, it should be noted that the same reference symbols or the same component designations are provided for the same components in the different described embodiments, wherein the disclosure content contained in the entire description can be switched to the same reference symbols according to the meaning Or on the same part with the same component name. Orientation descriptions selected in the description, such as top, bottom, side, etc., also relate to the directly described and illustrated figures and, when the orientation changes, are switched to the new orientation accordingly. Furthermore, individual features or combinations of features from the various exemplary embodiments shown and described can themselves represent independent, inventive or inventive solutions.

[0033] All statements of numerical ranges in the detailed description are to be understood as including any and all subranges from said numerical ranges, for example statements from 1 to 10 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com