High-speed electric main shaft device using sliding bearing and rolling bearing for composite support

A high-speed motorized spindle and rolling bearing technology, which is used in maintenance and safety accessories, metal processing machinery parts, metal processing equipment, etc. Deformation and other problems to achieve the effect of reducing temperature rise, improving radial stiffness and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

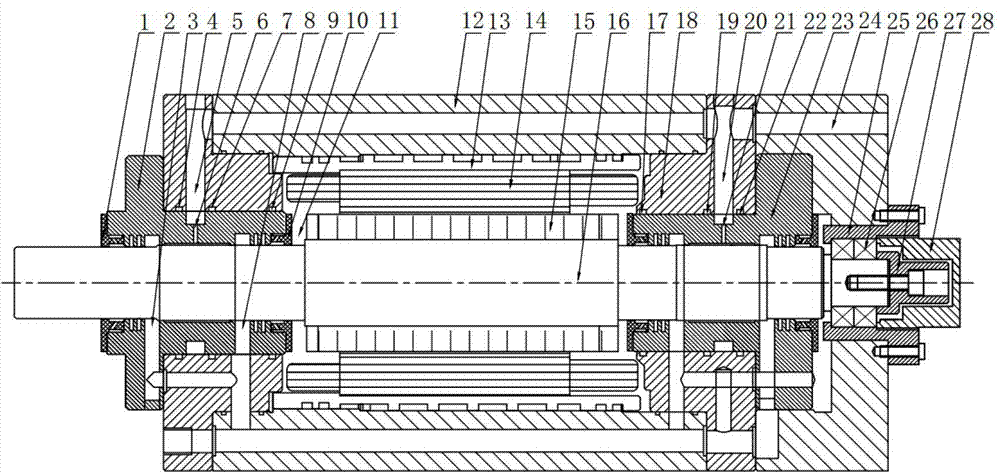

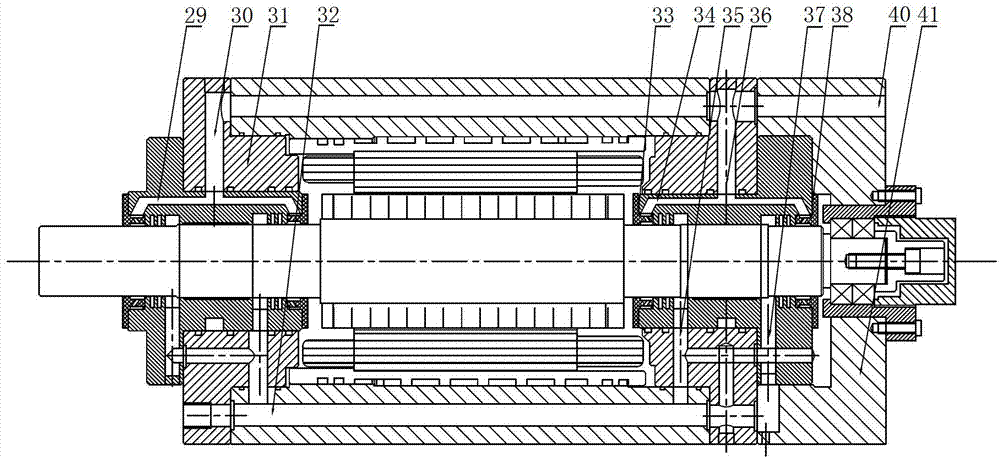

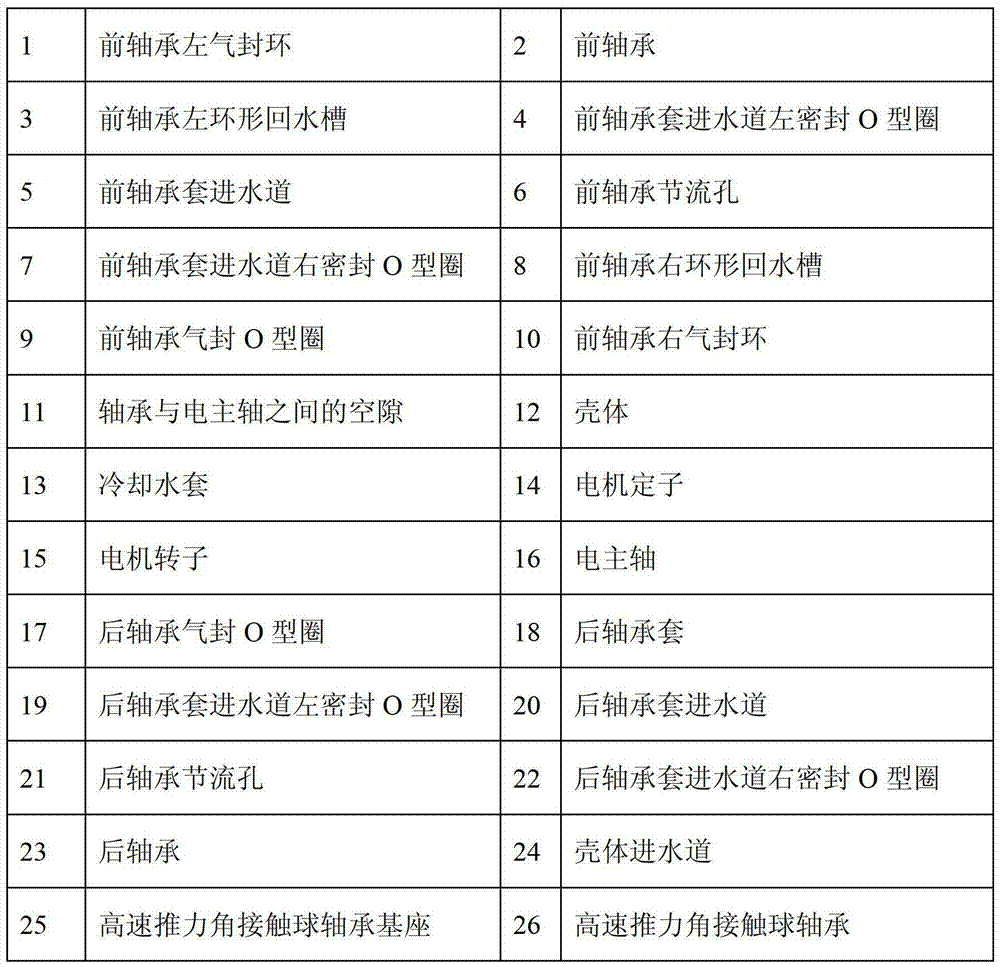

[0021] In order to realize the above functions, the present invention adopts the following technical solutions:

[0022] The motor base is used as the shell 12 of the electric spindle, and the motor stator 14 and the motor rotor 15 are installed in the middle of the electric spindle. Both ends are supported by two water-lubricated dynamic and static pressure sliding bearings, and a pair of high-speed thrust angular contact ball bearings are installed on the rear end. 26, to control the axial displacement of the electric spindle. The specific heat of water is large, and the change of viscosity with temperature rise is much smaller than that of mineral oil. Radial support bearings use water as lubricant. For the built-in electric spindle, when the speed increases, the water supply pressure of the bearing lubricating medium also increases correspondingly to maintain high rigidity, bearing capacity and stability, so the sealing performance directly affects the safe operation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com