Simple processing method of removing burrs of non-metal holder inner hole and end face junction

A cage and non-metal technology, applied in the field of bearing processing, can solve the problems of pinching the non-metal cage, reducing processing efficiency, hidden dangers and other problems, and achieving the effect of simple and easy processing method, reducing labor intensity and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

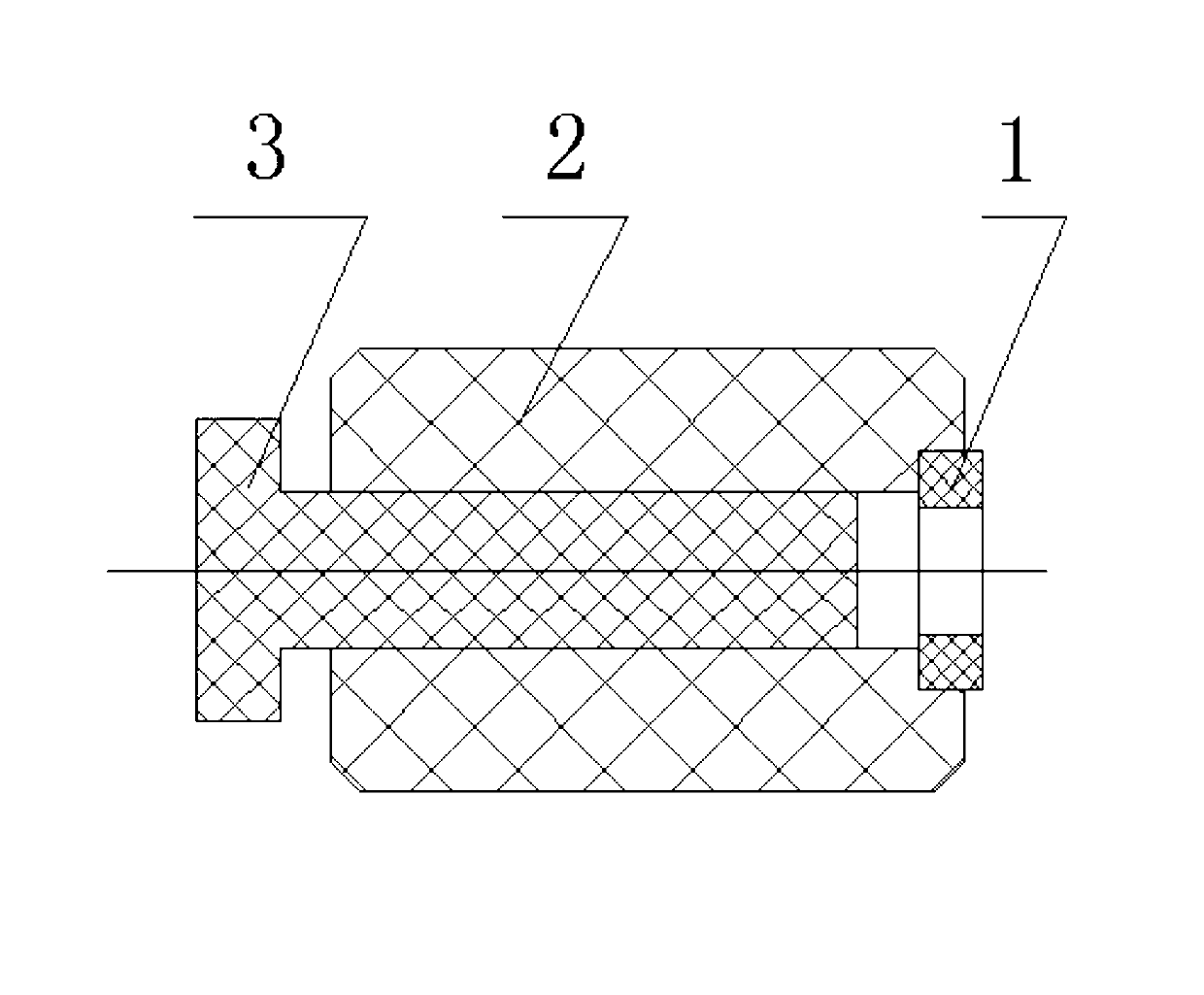

[0022] The invention is a simple processing method for removing burrs at the junction of the inner hole and the end face of a non-metallic cage. The non-metallic cage has an inner hole and two radial end faces, that is to say, the chamfer of the inner hole of the non-metallic cage There are burrs. The present invention is mainly aimed at small non-metallic cages. A special tool is used to remove the burrs. The special tool is the same as the special tool described in the background art, and is a commonly used deburring tool.

[0023] Let the outer diameter of the non-metallic cage be D and its width be L.

[0024] combine figure 1 , the present invention first makes the clamp 2 and the push rod 3, the inner hole of the clamp 2 is divided into a through hole and a clamp hole, the diameter of the through hole<the D, the diameter of the clamp hole=the D, the clamp The width of the hole=L / 2~L / 3, the push rod 3 is in an inverted T shape, the outer diameter of the small end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com