Preparation method for reinforced photocatalysis environment-friendly brick

A photocatalytic, environmentally friendly brick technology, applied in the field of resource recycling technology and material science, can solve problems such as insufficient photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

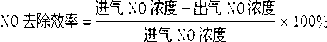

[0010] Mix chopped glass fibers accounting for 1.6% of the total mass of the surface layer of photocatalytic environmental protection bricks and 3.3% anatase nano-titanium dioxide, add appropriate amount of furnace bottom slag, cement and water, and stir evenly to prepare photocatalytic environmental protection brick samples. The flow rate is 1L / min, the NO concentration is 1ppm, and the measured NO removal efficiency is 48.3%.

Embodiment 2

[0012] Mix chopped glass fibers accounting for 0.8% of the total mass of the surface layer of photocatalytic environmental protection bricks and 3.3% anatase nano-titanium dioxide, add appropriate amount of sand, cement and water, and stir evenly to prepare photocatalytic environmental protection brick samples, with a flow rate of 1L / min, NO concentration 1ppm intake air, the measured NO removal efficiency is 39.5%.

Embodiment 3

[0014] Mix chopped glass fibers accounting for 0.8% of the total mass of the surface layer of photocatalytic environmental protection bricks and 3.3% anatase nano-titanium dioxide, add appropriate amount of furnace bottom slag, cement and water, and stir evenly to prepare photocatalytic environmental protection brick samples. The flow rate is 1L / min, the NO concentration is 1ppm, and the measured NO removal efficiency is 42.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com