Environmentally-friendly low-transparency type absolute black alumina silicate glass

A silicate glass, low-transparency technology, applied in the field of pure black high-alkali aluminosilicate glass system, can solve problems such as restricting product yield, ink scratching and falling off, and affecting appearance effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

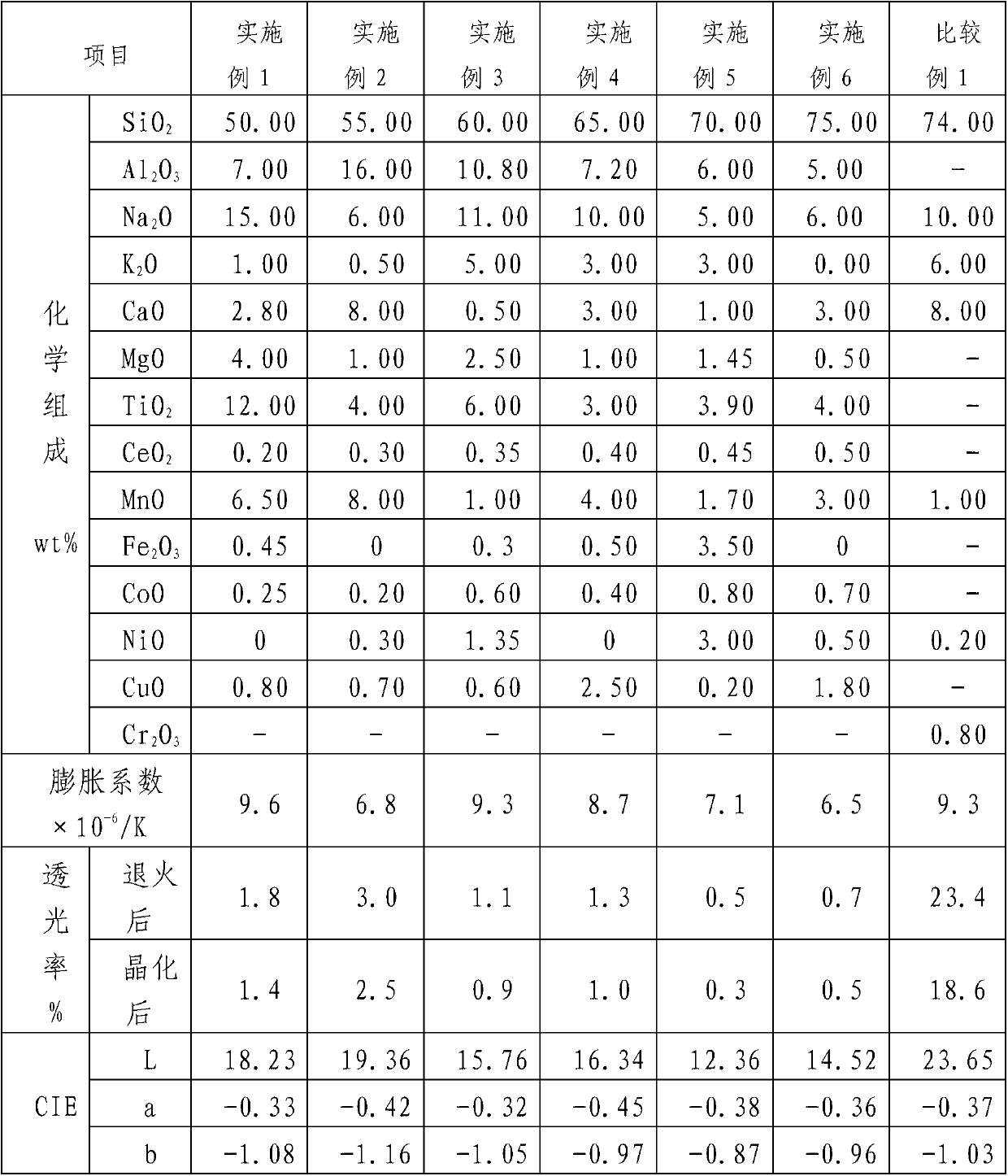

[0026] The glass composition of the present invention is composed of basic glass and coloring agent, the total amount is 100%; wherein, the chemical composition of basic glass is (wt%): SiO 2 50.00, Al 2 o 3 7.00, Na 2 O 15.00, K 2 O 1.00, CaO 2.80, MgO 4.00, TiO 2 12.00, CeO 2 0.20; black colorant chemical composition (wt%): MnO 6.50, Fe 2 o 3 0.45, CoO 0.25, NiO 0.00, CuO 0.80. After annealing treatment, after cutting 1mm slices and grinding and polishing, the average visible light transmittance is 1.8%, after crystallization treatment, the visible light transmittance is 1.4%, and the CIE Lab values are 18.23, -0.33, -1.08 respectively. From the results of Implementation 1, compared with the traditional non-environmentally friendly black glass of Comparative Example 1, the visible light transmittance after annealing decreased by 21.6% (23.4% in Comparative Example 1), and the visible light transmittance after crystallization treatment Reduced by 17.2% (Comparat...

Embodiment 2- Embodiment 6

[0028] The chemical composition of the glass of the present invention is as shown in Table 1, and the test results of Example 2-Example 6 are also shown in Table 1, and their color and spectral index are all better than Comparative Example 1, and have chemically enhanced material conditions, Therefore, I will not repeat them one by one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com