Novel anode plate and die thereof

An anode plate, a new type of technology, applied in electrodes, photography processes, instruments, etc., can solve the problems of low production efficiency, small electrolyte contact area, slow reaction rate, etc., to increase the contact area, speed up the reaction rate and production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

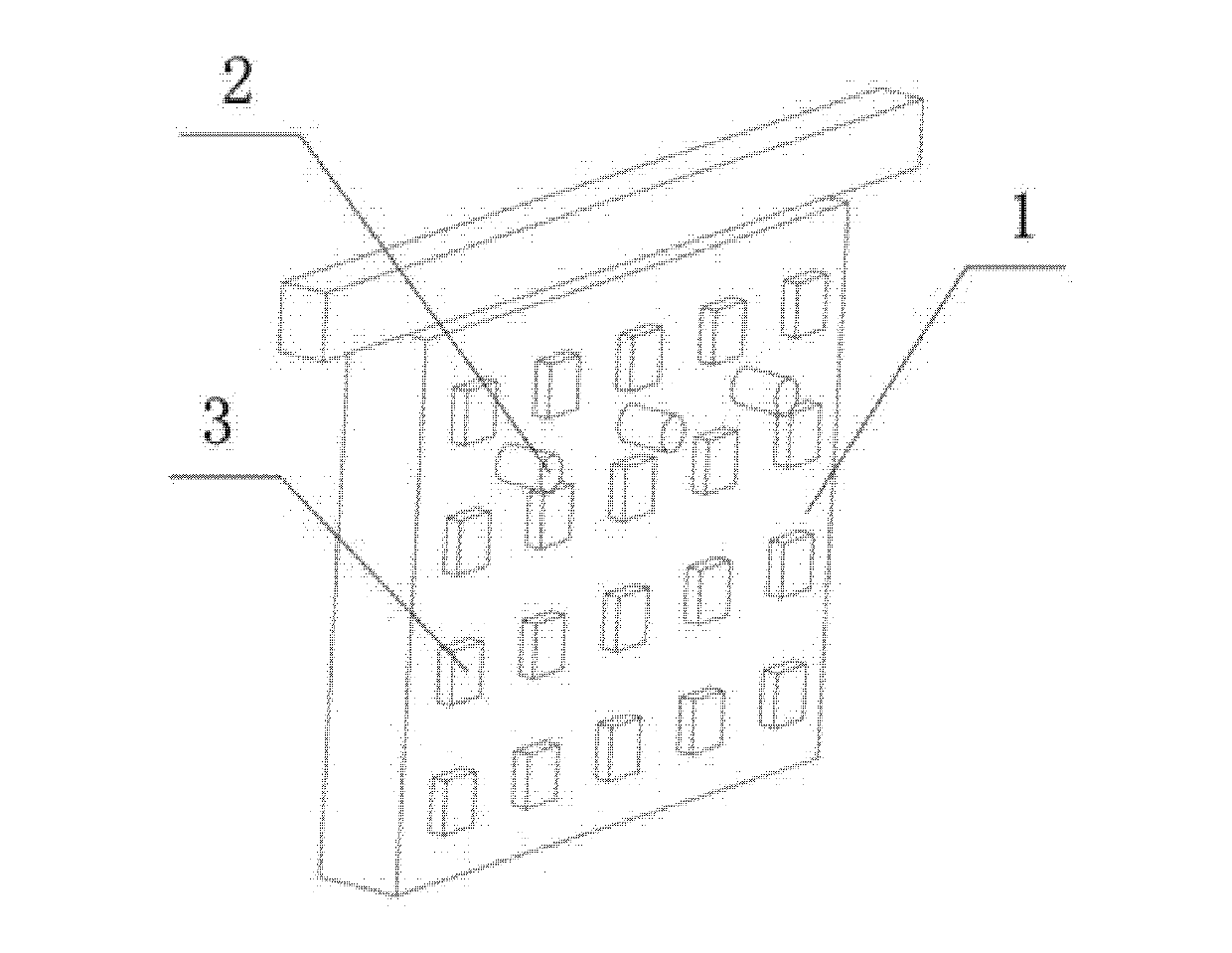

[0009] like figure 1 and figure 2 As shown, a novel anode plate of the present invention includes a copper plate layer 1 and a main board, the surface of the copper plate layer 1 has several protrusions 3, and insulating nails 2 are provided on the main board of the copper plate layer 1. The mold for producing the above-mentioned new anode plate is also provided with several concave parts 4 on the inner wall of the mold.

[0010] The copper plate layer 1 of the present invention has several protrusions 3, and compared with the smooth surface of the copper plate layer 1, the contact area with the electrolyte is increased, and the reaction rate and production efficiency of the electrolytic copper are accelerated. Insulating nails 2 are provided on the surface of the copper plate layer 1 to realize insulation protection for the anode plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com