Mushroom-like groove bi-direction rotating fluid dynamic pressure type machine sealing structure

A mechanical seal, fluid dynamic pressure technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of small leakage, wear resistance, poor wear resistance, end surface temperature rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

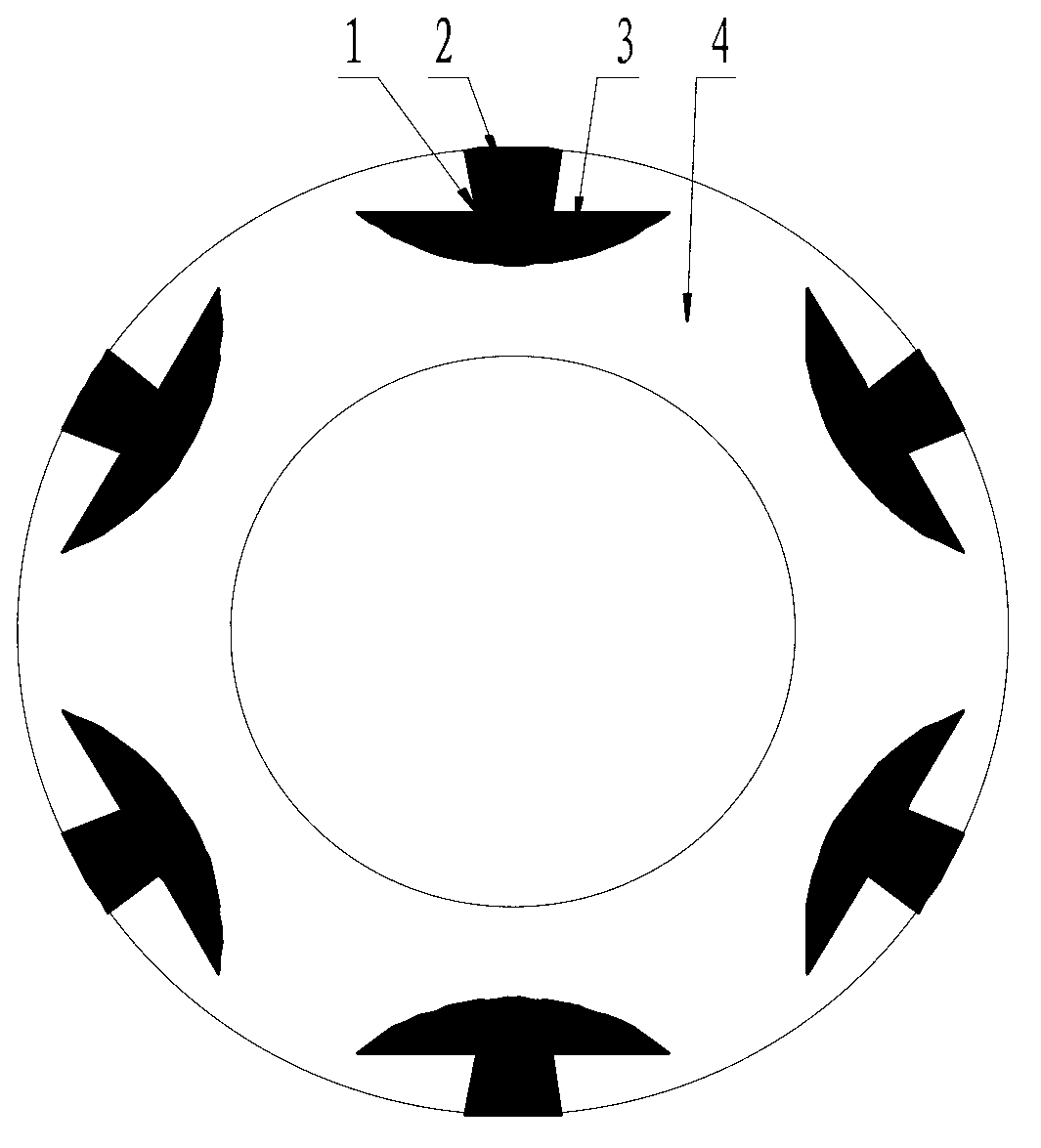

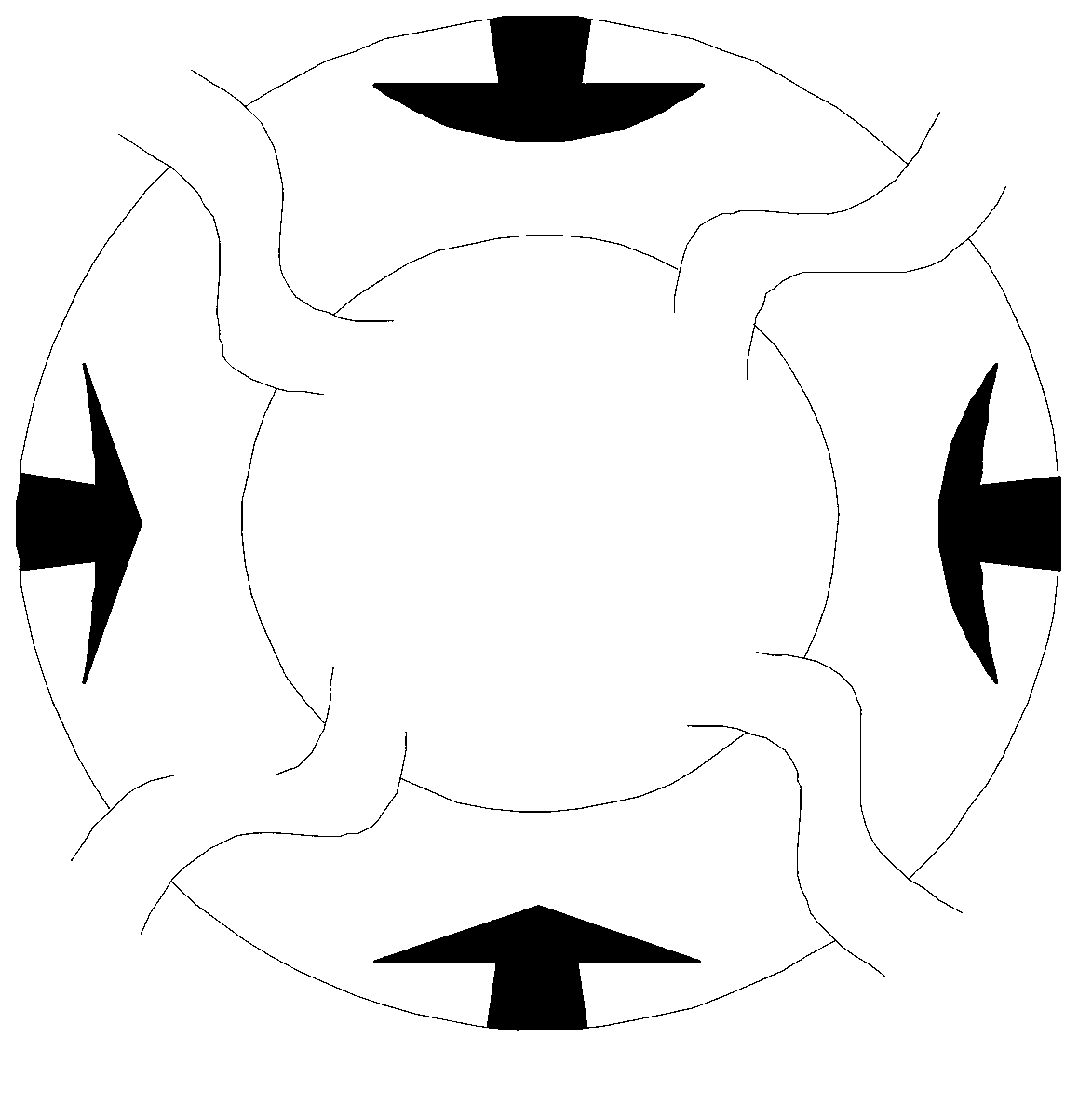

[0030] refer to figure 1 , figure 2 , Like a mushroom-shaped groove two-way rotating hydrodynamic mechanical seal structure, it includes a dynamic ring and a static ring of the mechanical seal. The sealing end surface of at least one sealing ring in the moving ring or the static ring has a plurality of mushroom-like grooves 1 uniformly distributed in the circumferential direction for liquid sealing. The characteristics of the mushroom-like groove 1 are drainage grooves 2 and return grooves. 3 consists of two parts. The drainage groove 2 extends radially, and the width gradually narrows along the radial direction of the end surface from the upstream, that is, the high pressure side, to the downstream, that is, the low pressure side; The shape is a circular arc or an elliptical arc or a curved arc or a straight line. The end of the drainage groove 2 is connected to the return groove 3, and the ungrooved area between the mushroom-shaped grooves is a sealing dam 4.

[0031] T...

Embodiment 2

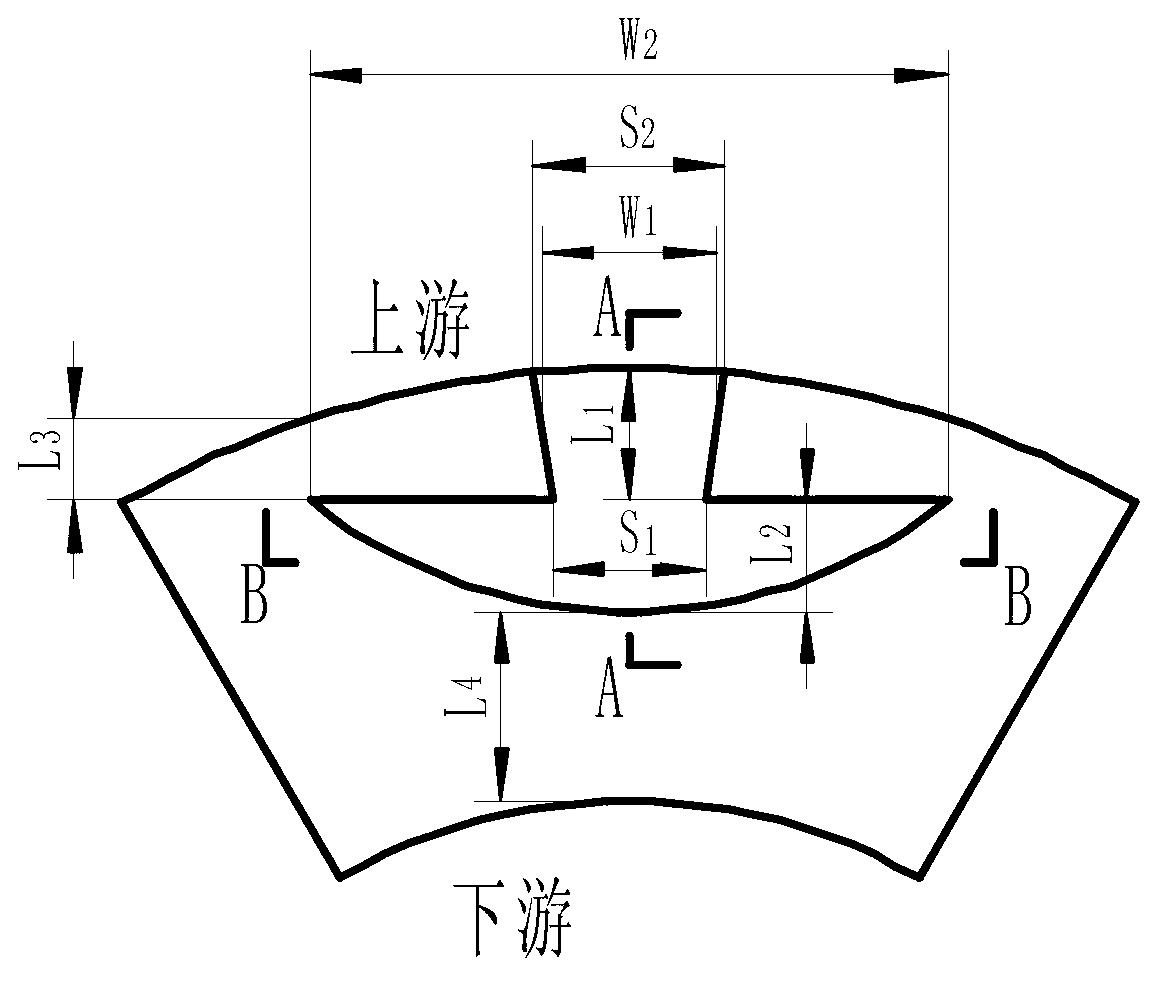

[0034] refer to image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 The difference between this example and Example 1 is that the drainage groove 2 becomes deeper in the radial direction, and the depth gradually becomes shallower along the radial direction of the end surface from upstream to downstream. Base bottom surface depth h of drainage groove 2 1 : 1μm≤h 1 ≤10μm; variable depth step height h 2 : 1μm≤h 2 ≤10μm; variable depth steps n 0 : 0≤n 0 ≤10; the aspect ratio of the deepening step of the drainage groove 2 γ 1 : 1≤γ 1 ≤5; the radial length L of the drainage groove 2 1 and seal face width W 1 Ratio L 1 / W 1 : 1 / 5≤L 1 / W 1 ≤1 / 2.

[0035] The drainage groove 2 becomes deeper along the radial direction, and the depth arrangement is to converge and become deeper along the radial straight line. The depth of the bottom surface of the drainage groove 2 is h 3 : 1μm≤h 3 ≤10μm; the depth h of the opening of the drainage groove 2 at the high pressure sid...

Embodiment 3

[0041] refer to Figure 8 The difference between this embodiment and Embodiment 1 and Embodiment 2 is that a sealing weir is added in the middle of the adjacent mushroom-shaped groove, so that the mushroom-shaped groove is separated from the circumferential direction, and it is also applicable to bidirectional rotation. All the other structures and implementations are the same as in Example one and Example two.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com