Method for observing crack propagation path of titanium alloy under plane strain state

A technology of plane strain and crack propagation, which is used in the preparation of test samples, material analysis using measurement of secondary emissions, etc. It can solve problems such as difficulty in meeting the plane strain state, and achieve the effect of simple form and preventing instantaneous fracture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The invention provides a method for observing the crack propagation path of a titanium alloy under a plane strain state, and the invention will be further described below in conjunction with the accompanying drawings.

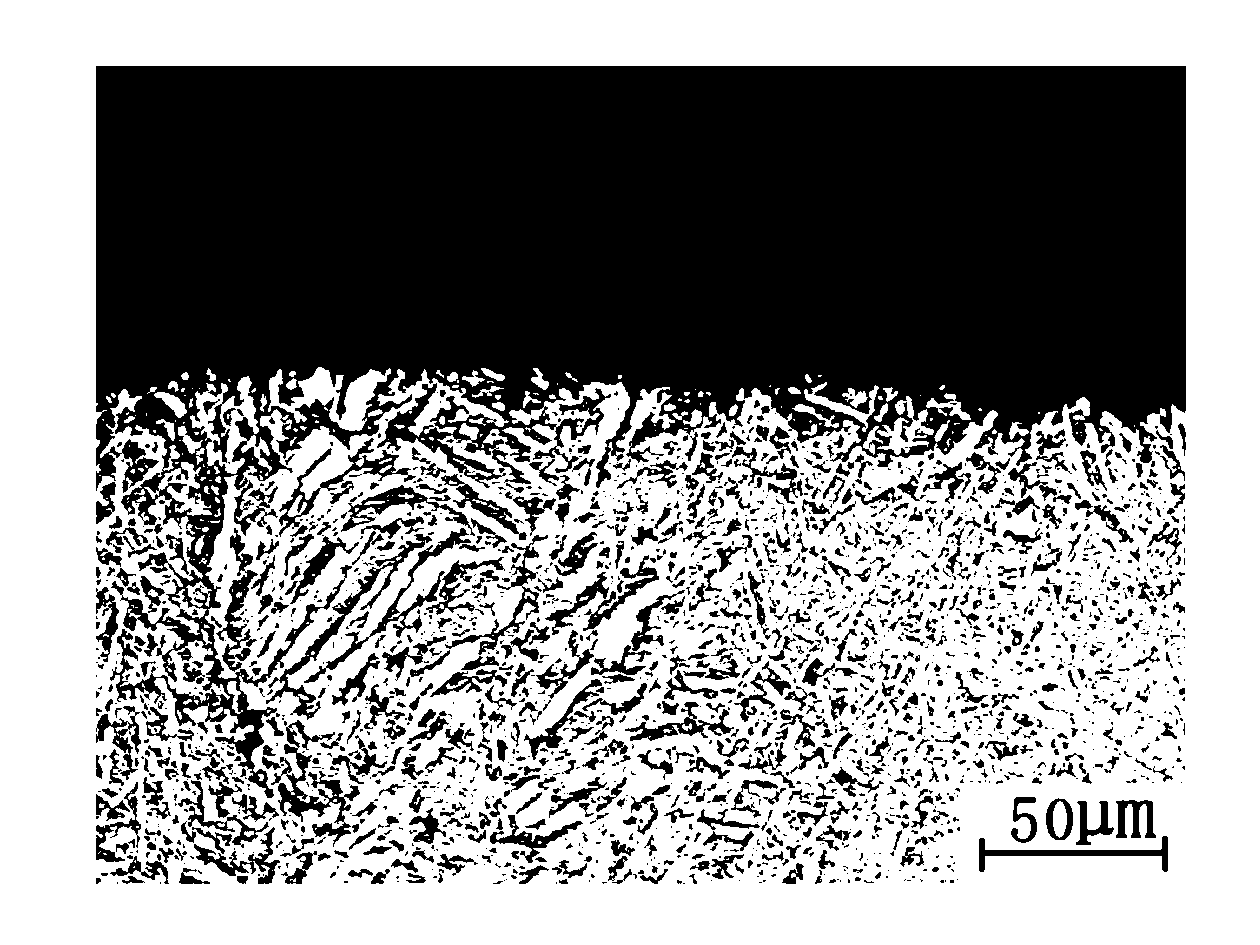

[0033] At present, the microscopic observation and analysis of the mode I crack propagation path under the plane strain condition of titanium alloy, if the plane strain fracture toughness (K IC) test specimens used in the fracture toughness test, when the loaded load reaches the maximum value, the rapid crack propagation in the titanium alloy material breaks instantly, because only the material on one side of the crack propagation path can be sampled observe, observe the effect as figure 1 As shown, it is difficult to judge whether the crack propagates in a transgranular or intergranular manner.

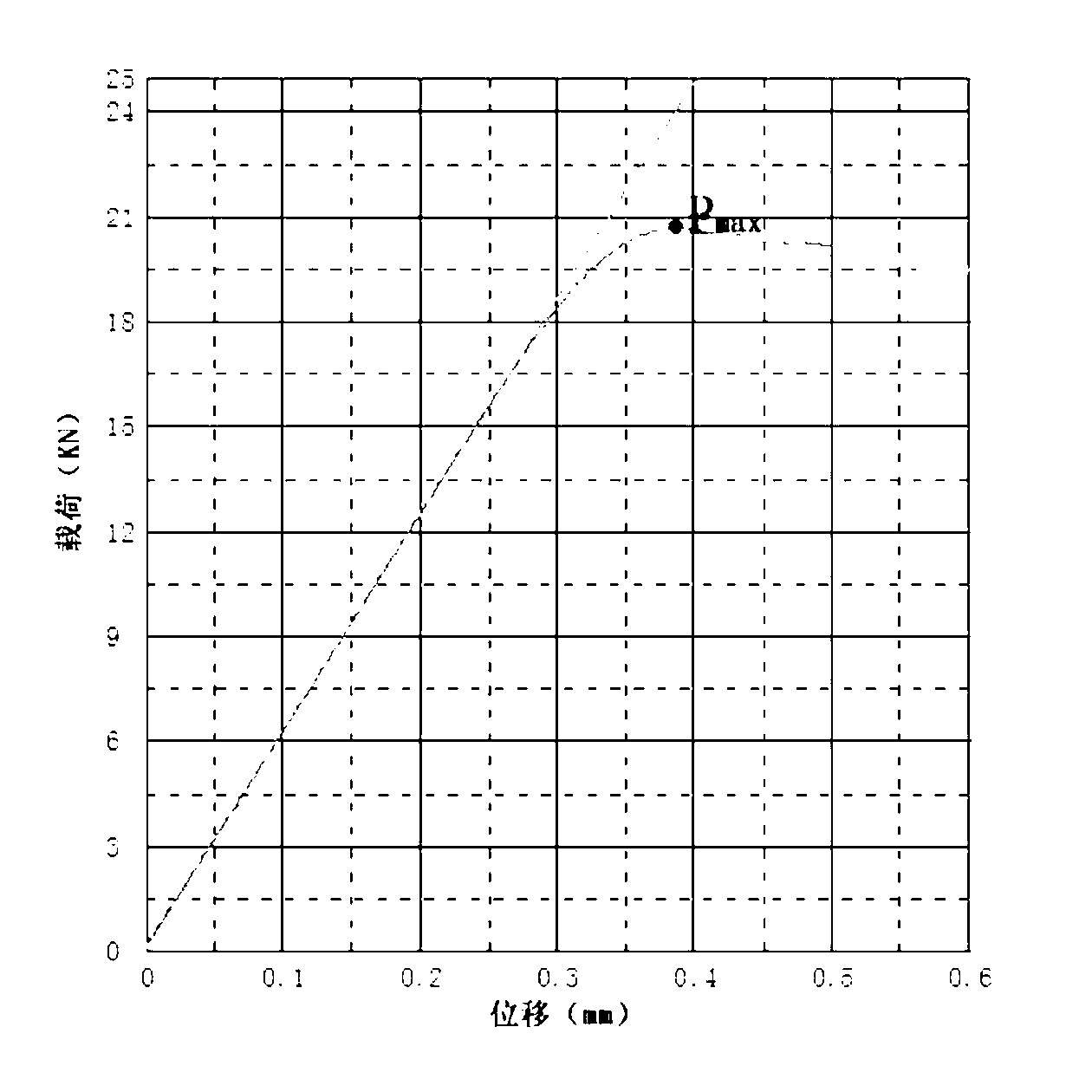

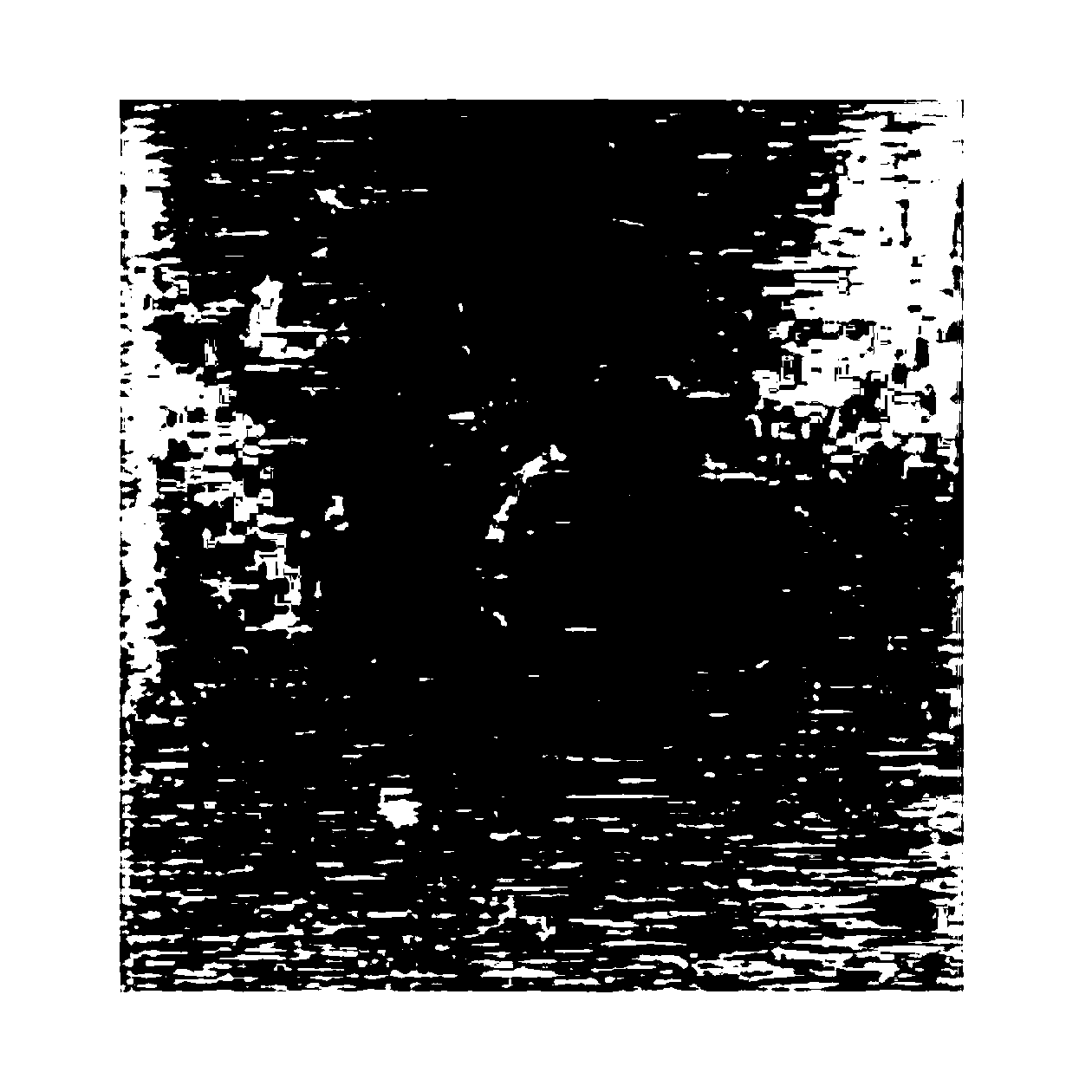

[0034] According to the method provided by the present invention, a new type of damage tolerance type two-phase titanium alloy Ti-62A is subjected to sample p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com