Intelligent Control System for Rope Arranging Mechanism

A control system and rope arranging technology, applied in the direction of control using feedback, etc., can solve the problems of no error compensation capability and real-time accurate following the arranging rope, the accumulation of angle deviation between the wire rope and the drum, and the inability to achieve real-time and accurate following, etc. Accurate follow-up, automatic commutation, timely commutation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

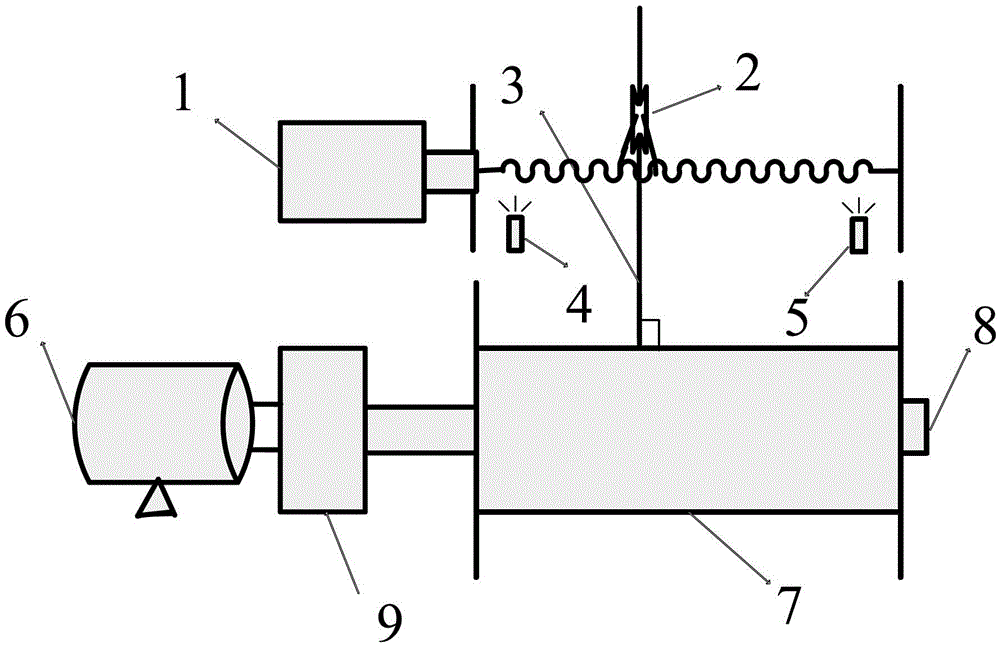

[0022] This embodiment describes an intelligent control system for the rope arrangement mechanism, its system structure is as follows figure 1 As shown, the intelligent control system includes a servo motor 1, a sheave 2, a motor 6, a drum 7, a position sensor 8 and a control processor ( figure 1 not shown in ), the servo motor 1 is connected with the guide wheel 2 through the screw used for transmission, the wire rope 3 is wound on the drum 7 after passing through the guide wheel 2, and the power output end of the motor 6 is connected with the drum 7, the said A speed reducer 9 is provided between the motor 6 that drives the drum 7 to rotate and the drum 7, and the drum 7 is provided with a position sensor 8 for detecting the position of the steel wire rope 3 winding on the drum 7. The position sensor 8 and the servo motor 1 are both Connected to the control processor.

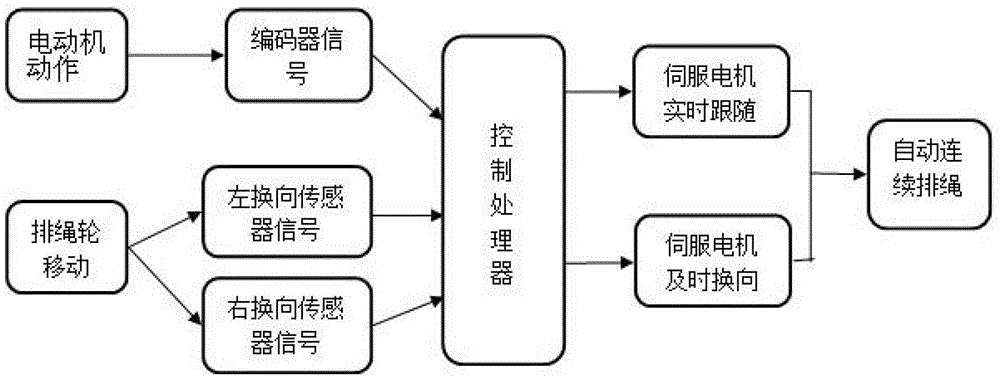

[0023] The control schematic diagram of this control system is as follows: figure 2 As shown, the speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com