Xenon lamp

A technology of xenon lamp and xenon gas, which is applied in the field of xenon lamp to achieve the effect of prolonging the service life, not easily deformed, and preventing short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

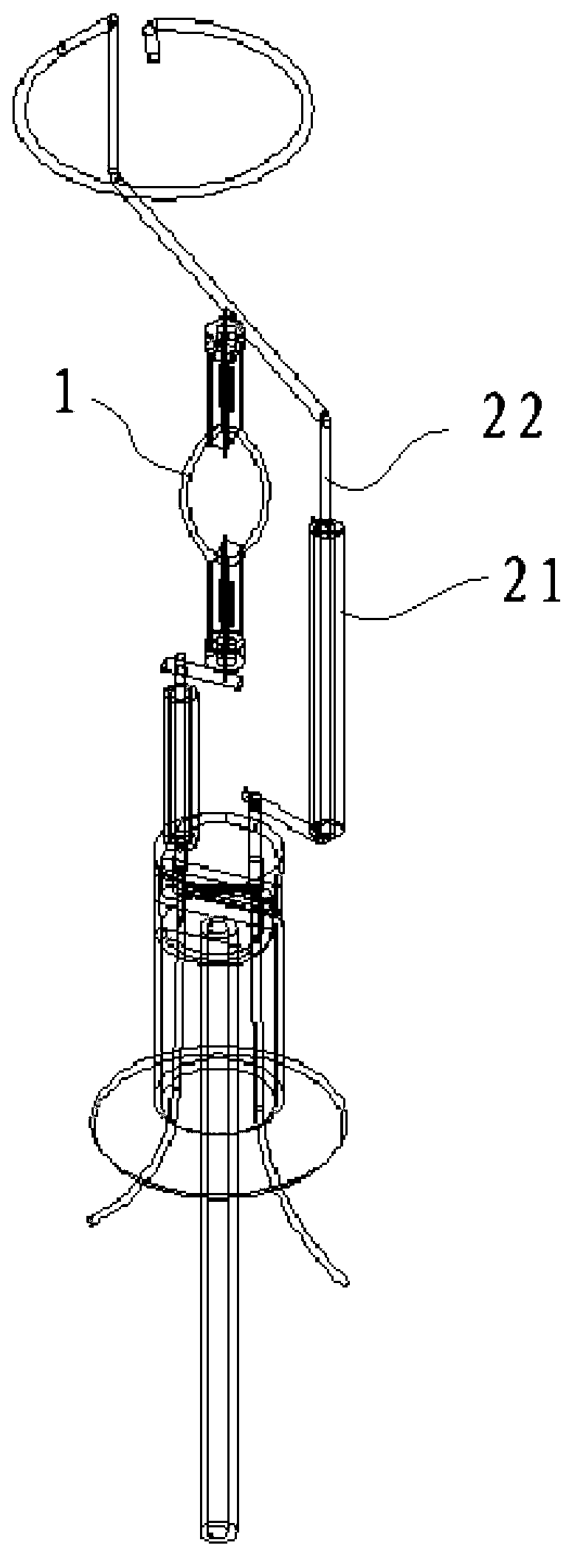

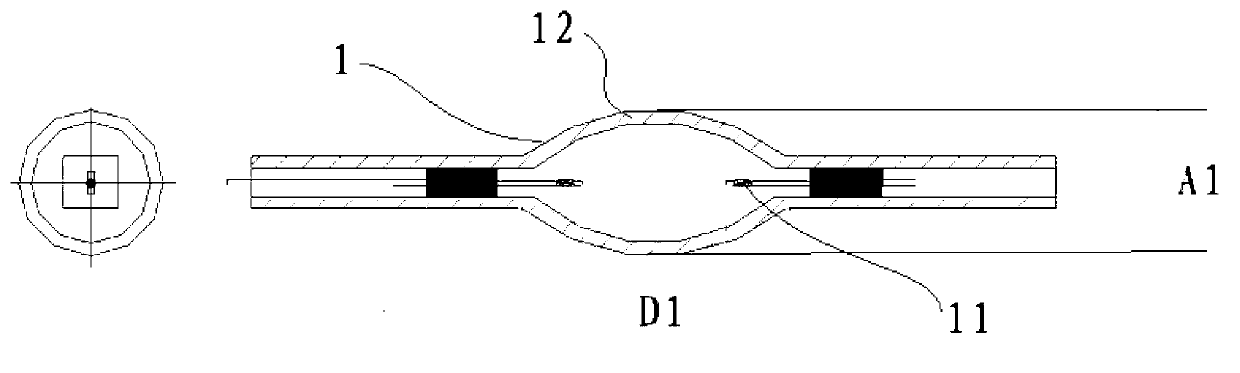

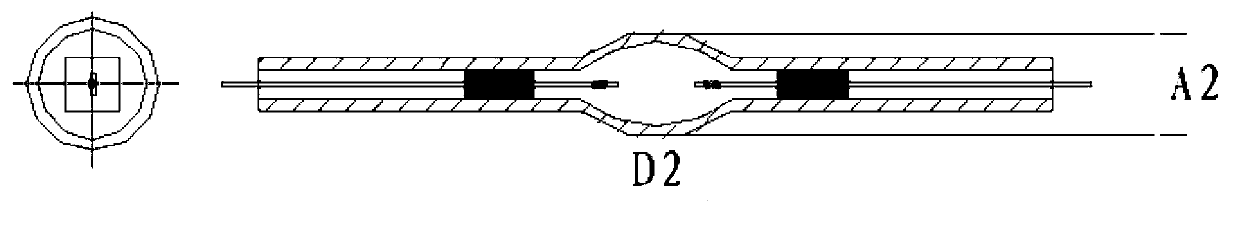

[0025] see figure 1 As shown, the xenon lamp includes a xenon bulb 1 and a protective layer 21 . The xenon bulb 1 includes a lamp bead 11 and a housing 12 . The lamp bead 11 is made of quartz glass. The lamp bead 11 is filled with metal halide and xenon gas, and is used for triggering and starting after the high voltage is applied. The middle part of housing 12 is an ellipsoid, and the long diameter of the housing is longer the higher the power, see figure 2 The long diameter D1 of the shown 150W housing is 20.0mm, and the short diameter A1 is 12mm; see image 3 As shown, the long diameter of the 75W shell is 13mm, and the short diameter A1 is 9mm. A protective layer to prevent electric shock between the conductors of the xenon lamp. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com