Device of neodymium iron boron automatic suppressing orientation forming and method

An automatic pressing and orientation forming technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of a lot of manpower and time, and achieve the effects of reducing production costs, improving production efficiency, and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

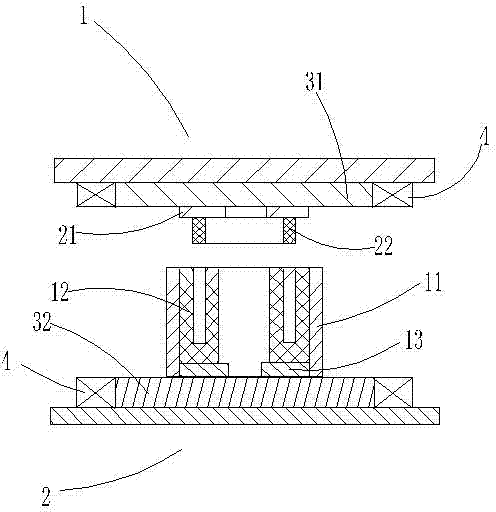

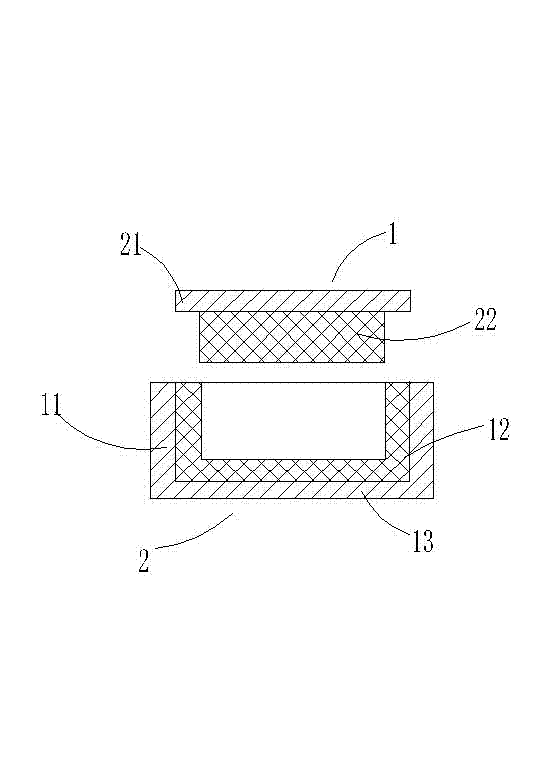

[0024] A device for NdFeB automatic pressing and orientation molding, comprising a fixed mold 1, a movable mold 2 matching the fixed mold 2, an electromagnet for providing an orientation magnetic field, and an excitation coil 4 wound on the electromagnet , the fixed mold 1 includes a metal mold case 11 and a rubber mold 12 arranged in the metal mold case 11, and the movable mold 2 includes a steel upper pressure head 21 and a rubber fixed under the steel upper pressure head 21 Upper pressing head 22.

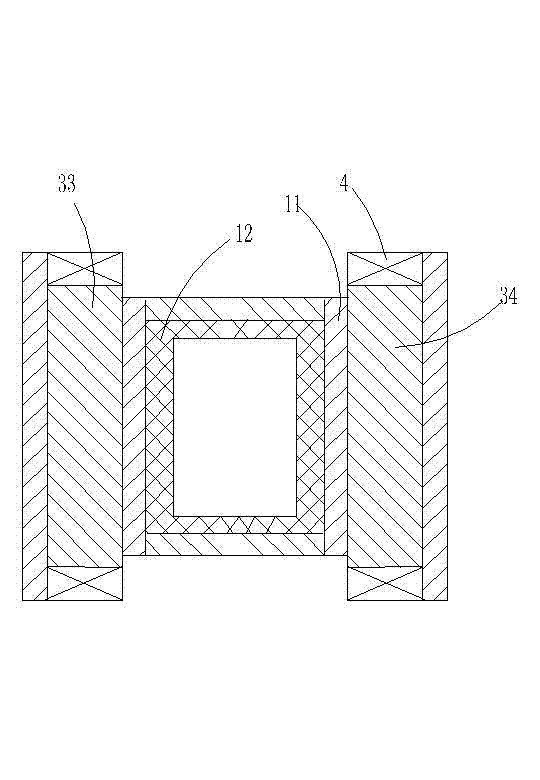

[0025] Wherein, the electromagnet includes a left electromagnet 33 and a right electromagnet 34, the left electromagnet 33 is fixed on the left side of the metal mold cover 11, and the right electromagnet 34 is fixed on the metal mold cover 11 On the right side of the upper side, the steel upper pressure head 21 is a non-magnetic steel upper pressure head, and the lower side of the metal mold cover 11 can be used as a steel lower pressure head 13, and the steel lower pressure he...

Embodiment 3

[0029] A method for pressing NdFeB by using the above-mentioned device, comprising the following steps: when the upper end surface of the rubber mold 12 is filled with magnetic powder, the electromagnet starts to provide an orientation magnetic field, and the upper pressing head 22 of the rubber descends, so that the magnetic powder moves in the up and down direction When compressed, the density increases to 3.9-4.1 g / cm 3 , at this time, the lower end surface of the steel upper pressure head 21 reaches the upper end surface of the rubber mold 12, and the magnet blank is subjected to pressure in three directions: up and down, left and right, and front and rear. When the density of the magnet blank reaches 4.6 grams / cm 3 —4.7 g / cm 3 When the orientation magnetic field drops to zero, a demagnetization magnetic field is provided. After the demagnetization magnetic field drops to zero, the upper pressing head 22 of the rubber rises, and the magnet blank is sucked out from the rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com