Preparation method of functionalized manganese dioxide nanowire membrane

A manganese dioxide nanometer and functionalization technology, applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of complex vapor deposition process, high technical requirements, hindering the industrial application of preparation methods, etc., and achieve simple process and strong applicability , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

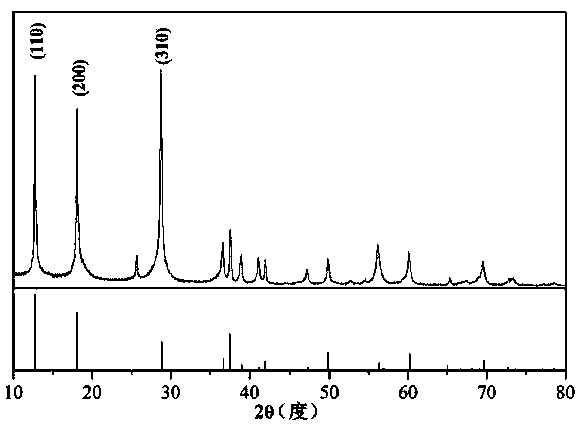

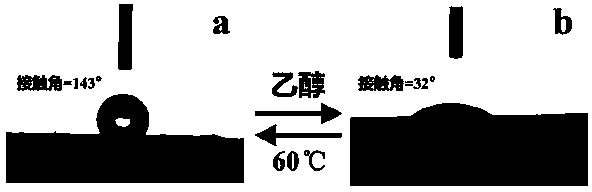

[0017] 0.2 g of manganese dioxide nanowires were ultrasonically dispersed in a 20 ml methanol alcohol flask, 0.4 g of n-octyltrimethoxysilane was added, and refluxed in a water bath at 50° C. for 8 hours to obtain a functionalized manganese dioxide nanowire dispersion. The above dispersion liquid was added in batches into a polytetrafluoroethylene circular tank, dried at 60° C. for 12 hours, and the functionalized manganese dioxide nanowire film could be obtained by peeling off the surface of the polytetrafluoroethylene.

Embodiment 2

[0019] 0.2 g of manganese dioxide nanowires were ultrasonically dispersed in a 20 ml toluene flask, 0.1 g of n-decyltrimethoxysilane was added, and refluxed in an oil bath at 110° C. for 2 hours to obtain a functionalized manganese dioxide nanowire dispersion. The above dispersion was vacuum filtered with a separatory funnel, washed three times with ethanol, and dried at 60° C. for 12 hours to obtain a functionalized manganese dioxide nanowire membrane.

Embodiment 3

[0021] 0.2 g of manganese dioxide nanowires were ultrasonically dispersed in a 20 ml toluene flask, 0.2 g of n-octyltriethoxysilane was added, and refluxed in a water bath at 90° C. for 10 h to obtain a functionalized manganese dioxide nanowire dispersion. The above dispersion was vacuum filtered with a separatory funnel, washed three times with ethanol, and dried at 60° C. for 12 hours to obtain a functionalized manganese dioxide nanowire membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com