Production method of methyl cyclopentenolone via amination and step-by-step reaction

A technology of methylcyclopentenol ketone amine and production method, which is applied in chemical instruments and methods, organic chemistry, preparation of organic compounds, etc., can solve problems such as many side reactions, pollute the surrounding environment, and large product odor, and achieve The effect of shortening the reaction time of amination, solid environmental protection foundation, and increasing production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

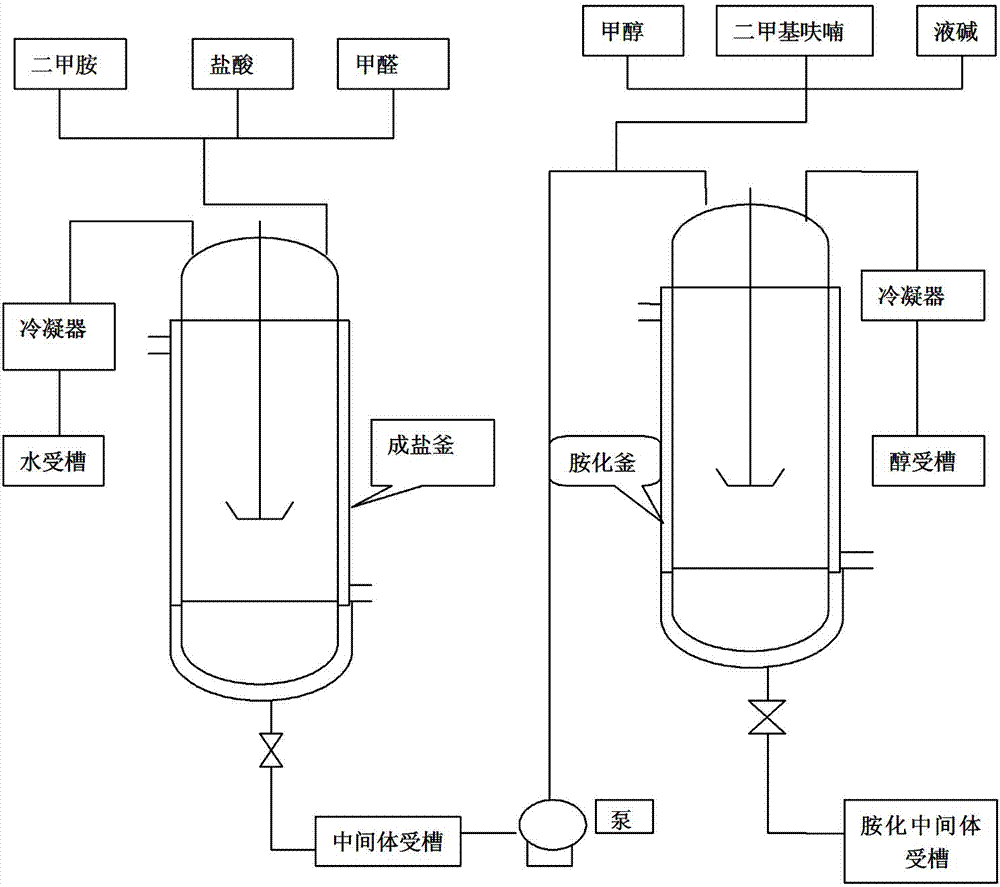

[0016] First, add 700L of dimethylamine and 400L of hydrochloric acid to the amination salt-forming kettle, the pH value is about 6.5, and carry out the dehydration reaction. The temperature is controlled at 90°C, and the reaction is 12 hours. After the salt is formed, 570L of formaldehyde is added to dissolve the reaction. The reaction intermediate was obtained in 6 hours.

[0017] The reaction intermediate is pumped into the amination kettle, add 270L methanol and 400L dimethylfuran to carry out amine methylation reaction, the reaction temperature is 40°C, and the time is 8 hours. After the reaction is completed, it is heated to 60°C to dealcoholize, and then add lye 400L, the pH value is about 10, carry out alkalization reaction, the reaction temperature is 40 ℃, 4 hours, obtain about 700L of amination intermediate. The aminated intermediate undergoes ring-opening and ring-closing rearrangement by adding acid and base, and then hydrolyzes to obtain methylcyclopentenolone. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com