Aminated lignin as well as preparation method and application thereof

A technology for aminating lignin and lignin, which is applied in the fields of building components, tar pitch/petroleum pitch/natural pitch processing, building insulation materials, etc. To avoid problems such as high degree of connection, achieve the effects of shortening the amination reaction time, high amination grafting rate, and increasing active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: Degradation-acidolysis of lignin

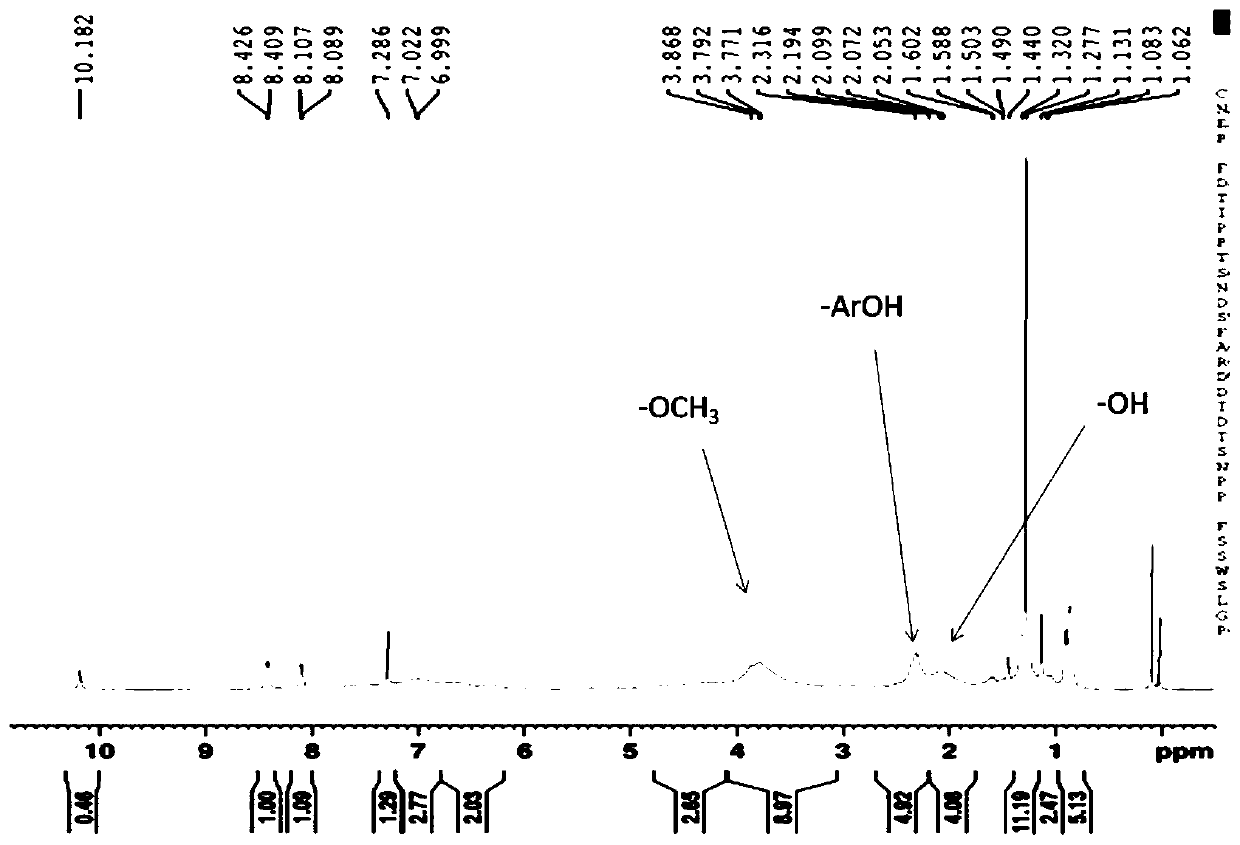

[0039] In a 50mL reaction bottle, add 5g of lignin dissolved in 20mL of DMF, then add 5g of HBr with a mass fraction of 10%, and react in a microwave reactor at 90°C for 30min. After the reaction, the reactant was cooled to room temperature, added dropwise to 200 mL of 2% hydrochloric acid solution, stirred for 30 min, centrifuged, the precipitate was taken, washed with distilled water, washed until the supernatant was neutral, freeze-dried, Its NMR spectrum is as figure 1 Shown; the changes of molecular weight and hydroxyl before and after acid hydrolysis were detected by NMR and GPC [1] , the results are shown in the table below:

[0040] Table 1 Changes in molecular weight and phenolic hydroxyl groups of lignin before and after acidolysis

[0041]

Embodiment 2~5

[0042] Embodiment 2~5: the preparation of chlorohydrin intermediate

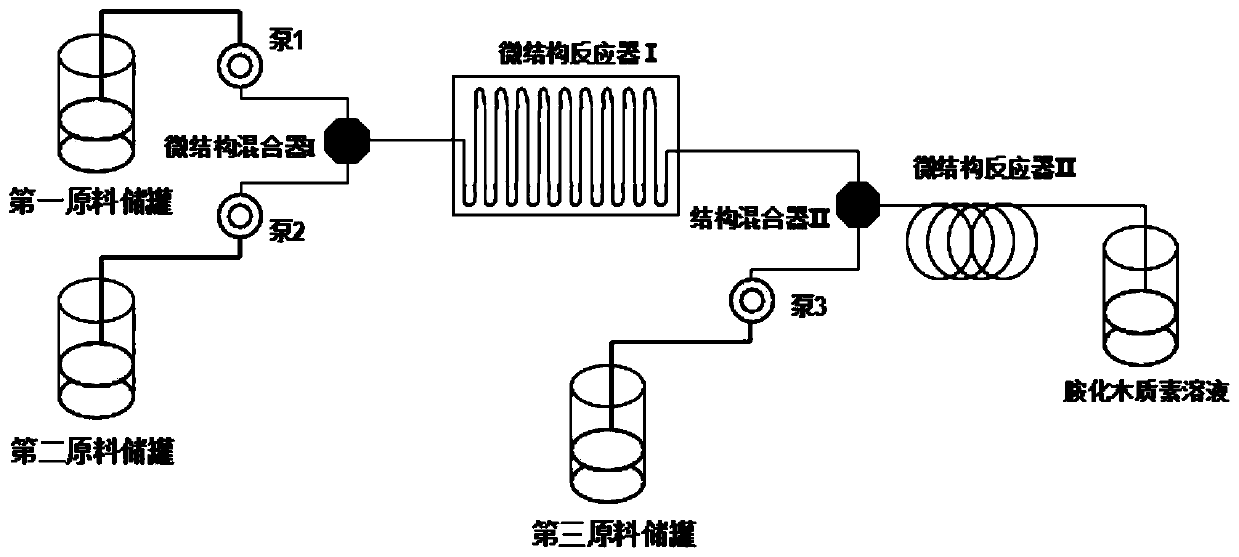

[0043] The aqueous solution of epichlorohydrin is configured in the first raw material storage tank, and the concentration of epichlorohydrin is 3mol / L, and the aqueous solution of aminating reagent diethylamine is configured in the second raw material storage tank, and the concentration is 3mol / L. Pump the first raw material storage tank (epichlorohydrin solution) and the second raw material storage tank (diethylamine aqueous solution) into the first micro-mixer in the microchannel reaction device according to the volume flow ratio of 1:1, mix and flow into The first microreactor, at a certain temperature, retain for a period of time, and take the reaction liquid GC-MS detection from the microstructure reactor I [2] Quantitative detection was carried out afterward, and the detection results are as follows:

[0044] Table 2 Epichlorohydrin and diethylamine reacted through microchannels and the intermediate ...

Embodiment 6~17

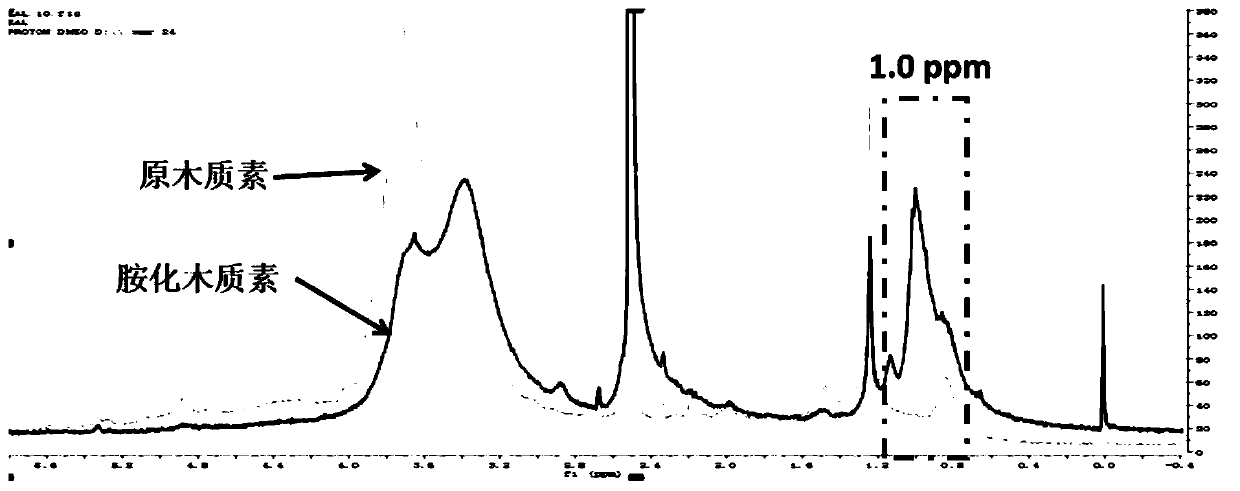

[0051] In the third raw material storage tank, configure acidolysis lignin alkali solution (prepared in embodiment 1), the proportioning of acidolysis lignin and (0.3mol / L) sodium hydroxide solution is 100g: 1L, the third raw material storage tank (acidolysis lignin alkaline solution) and the flow rate of the outlet of the first microreactor (embodiment 5), according to the volume flow ratio is 1:1 to pump in the microstructure reactor II, at a certain temperature, keep for a period of time, take The reaction liquid from the second micro-reactor is nano-filtered and spray-dried with a nano-filtration membrane with a molecular weight cut-off of 200-500 Da, and then elemental analysis and NMR are carried out. 1 H NMR ( image 3 ) for detection, the elemental analysis detection results are as follows:

[0052] Table 3 Nitrogen content of acid-hydrolyzed lignin through microchannel reaction and aminated lignin

[0053]

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com