Method for chemically regulating particle size of azobisformamide

An azodicarbonamide and chemical regulation technology, applied in the chemical industry, can solve the problems of unable to meet market demand, wide product particle size distribution, low product addition, etc., to improve market competitiveness and economic benefits, improve product quality and product quality. The effect of product added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

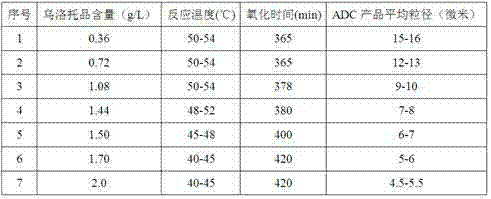

[0010] Add the mother liquor into the 130L reactor, then add 25Kg of biurea, catalyst; add sulfuric acid until the acidity of the mother liquor is 4mol / L, control the reaction temperature at 40~60°C, liquid-solid 1:4, urotropine in the feed liquid Content 0.36~2.0g / L, NaCLO 3 The concentration is 50%, the rotameter is used to add dropwise, and the mother liquor is recycled and applied repeatedly. The particle size of the foaming agent ADC product is detected by the SKC-2000 light-transmitting particle size distribution instrument (manufactured by Japan Co., Ltd. Qingxin Enterprise).

[0011] Table 1 (pilot test) List of particle sizes of foaming agent ADC produced by sodium chlorate oxidation of biurea

[0012]

Embodiment 2

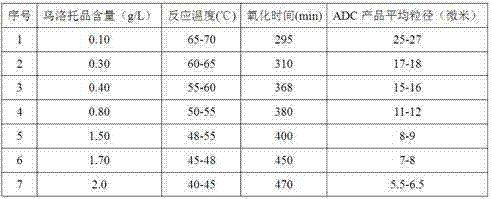

[0014] Add the mother liquor into the 130L reactor, then add 25Kg of biurea, add catalyst and co-catalyst, add sulfuric acid until the acidity of the mother liquor is 6.5mol / L, control the reaction temperature at 50~70℃, liquid-solid 1:4, urethane The content of tropin in the feed liquid is 0.1-2.0g / L, the concentration of hydrogen peroxide is 60%, the rotameter is used to add dropwise, and the mother liquor is recycled and applied mechanically. Diameter distribution meter detection (manufactured by Qingxin Enterprise, Japan Co., Ltd.).

[0015] Table 2 (pilot test) List of particle sizes of foaming agent ADC produced by hydrogen peroxide oxidation of biurea

[0016]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com