A walking excavator remote control system

A remote control system, excavator technology, applied in the direction of earth moving machine/shovel, construction, etc., can solve the problems of inconvenient maintenance, high manufacturing cost, high price, etc., to save transformation cost, retain reliability, and compact size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

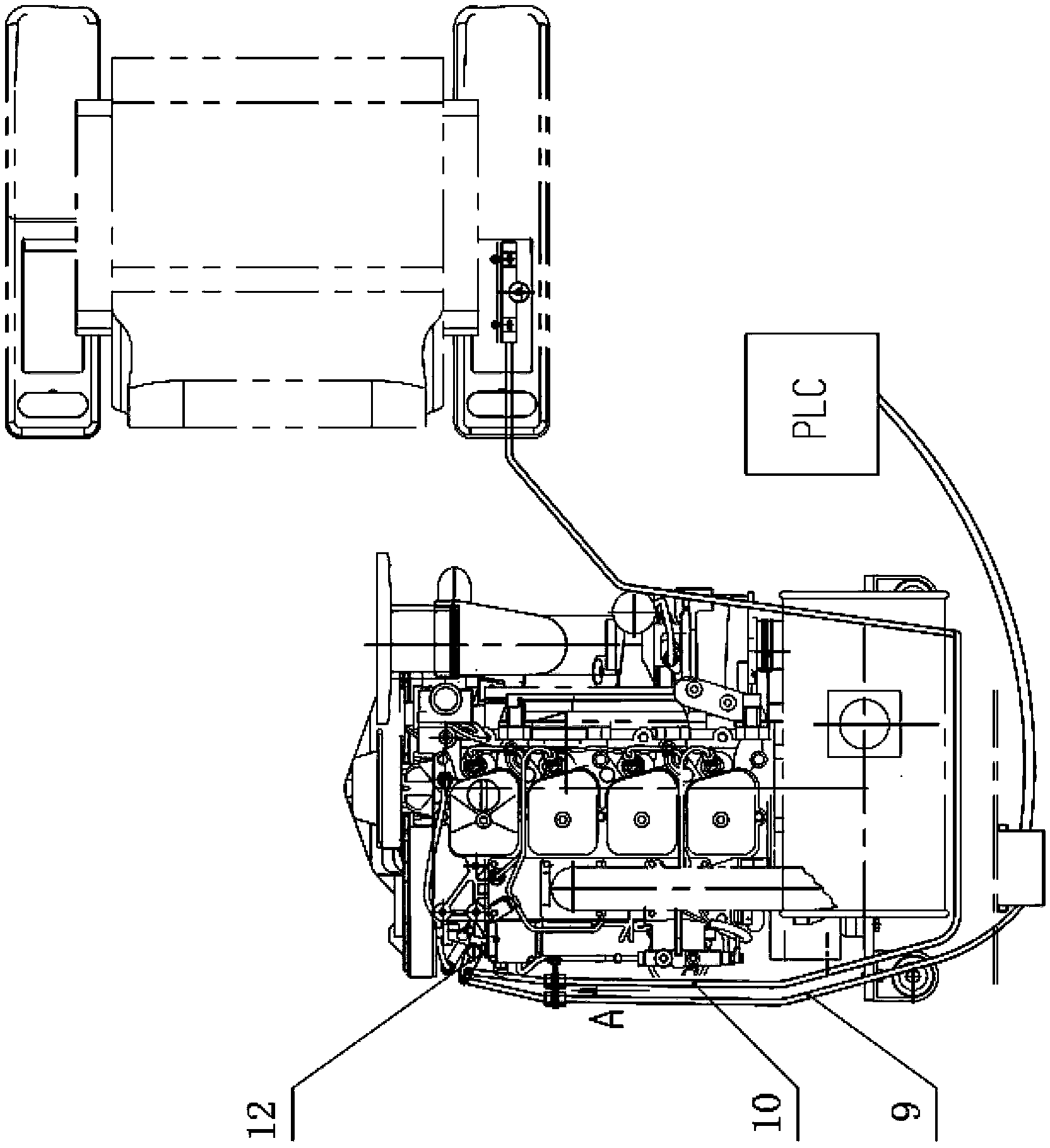

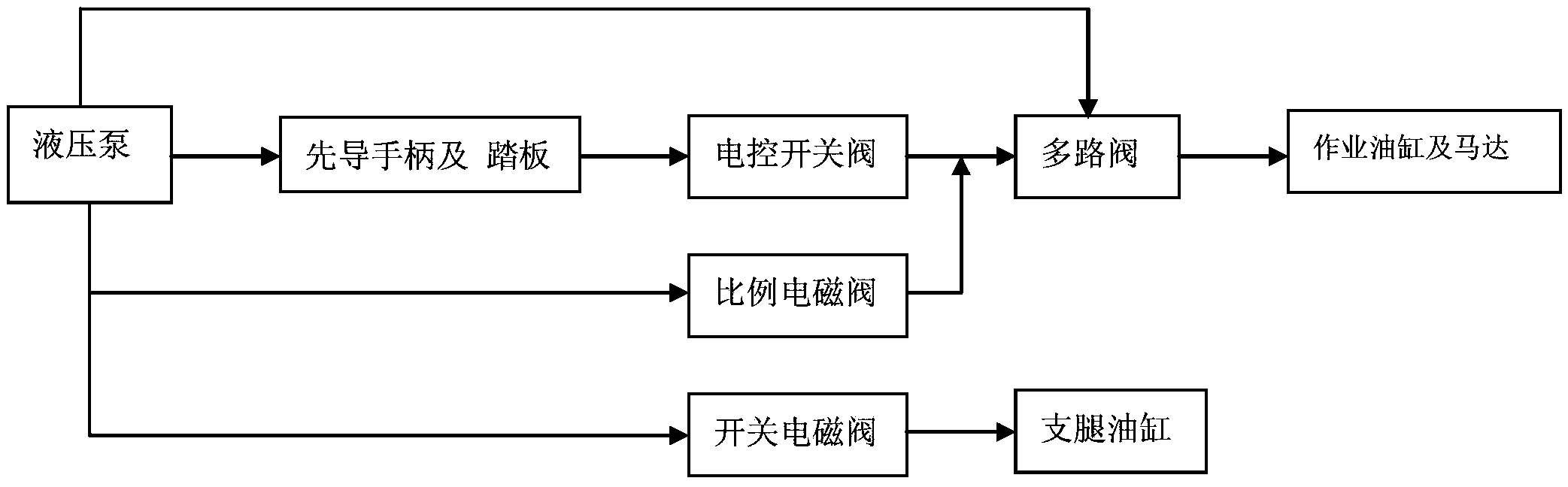

[0024] Such as figure 1 As shown, the hydraulic pump is electrically connected to the electric control switch valve through the pilot handle and the pedal, and the electric control switch valve is electrically connected to the working cylinder and the motor through the multi-way valve. One end of the proportional solenoid valve is electrically connected to the output end of the hydraulic pump, and the other end is connected to the Between the electronic control switch valve and the multi-way valve; one end of the switch solenoid valve is electrically connected to the output end of the hydraulic pump, and the other end is electrically connected to the input end of the outrigger cylinder. Electric control on-off valve is used for switching between hydraulic pilot control and electric proportional pilot control; proportional solenoid valve is used for remote pilot operation. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com