Chemical nickeling solution cooler

A technology of solution cooling and electroless nickel plating, which is applied to the types of heat exchangers, heat exchanger shells, indirect heat exchangers, etc., and can solve problems such as complex and bloated structures, corrosion and contamination of plating solutions, nickel ion deposition, and scaling , to achieve the effect of simple and compact structure, adapt to the detection requirements, and ideal use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

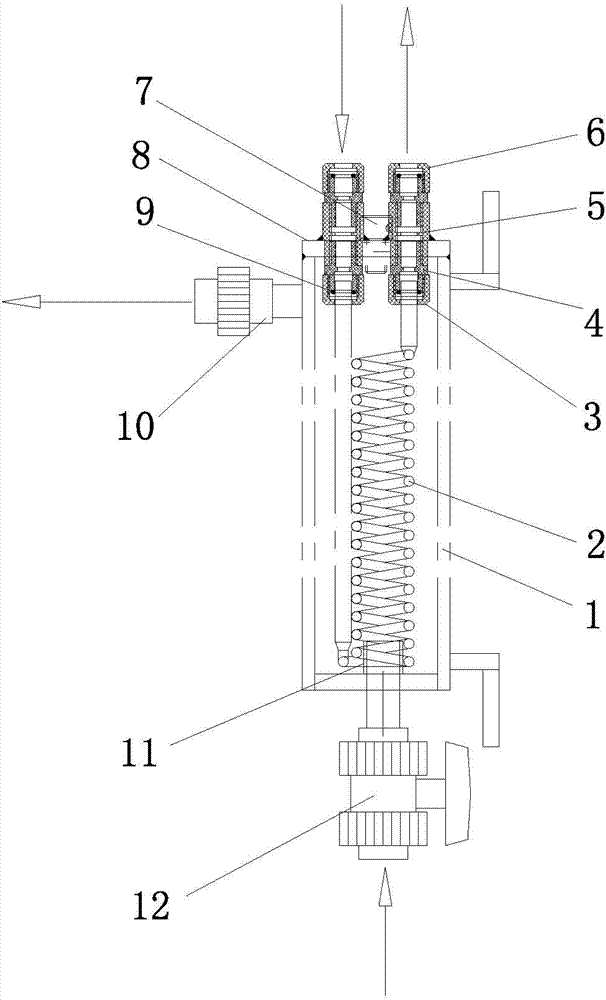

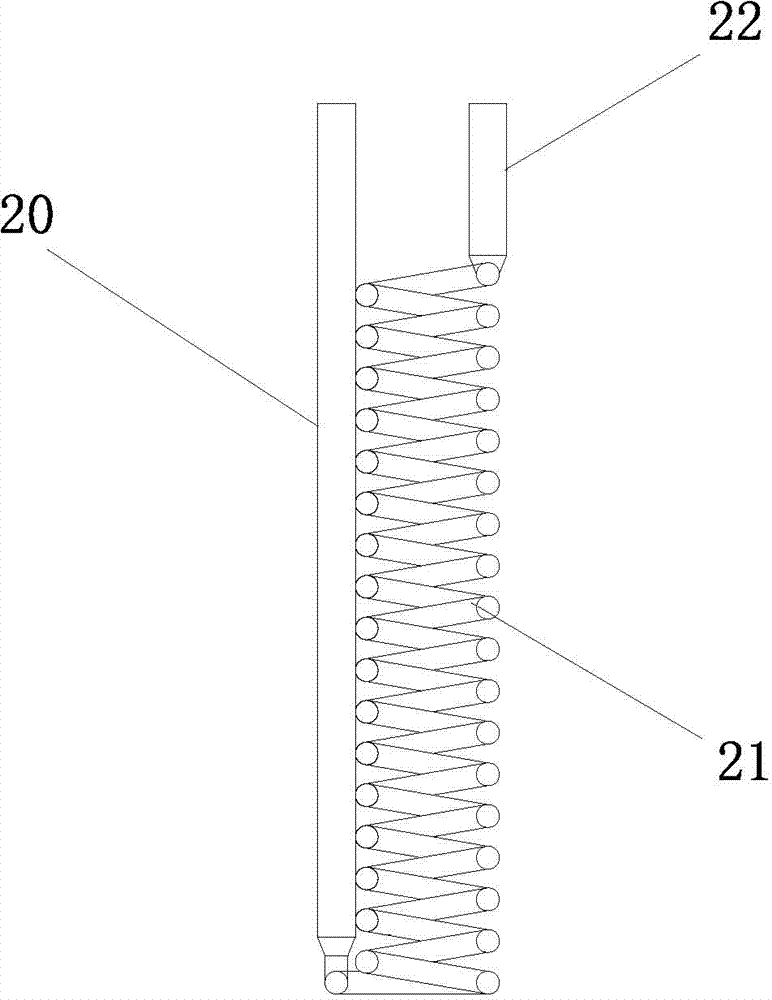

[0014] Such as figure 1 and figure 2 As shown, the electroless nickel plating solution cooler of the present invention has a structure as follows: it includes a liquid storage tank 1, a bung 8, a glass cooling pipe 2, a cooling water inlet 12, and a cooling water outlet 10; the glass cooling pipe 2 includes a straight pipe section 20, a spiral pipe section 21 and a joint section 22 integrally formed by a mold, the lower end of the straight pipe section 20 communicates with the lower end of the spiral pipe section 21, and the upper end of the spiral pipe section 21 communicates with the joint section 22. The nozzle of the straight pipe section 20 and the nozzle of the joint section 22 are in the same direction, which is convenient to connect the solution inlet and the solution outlet, making the structure more compact; the bung 8 is arranged on the top of the liquid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com