A navigation sheet and navigation method for dry engraving equipment

A kind of equipment and dry etching technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of high incidence of etching defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

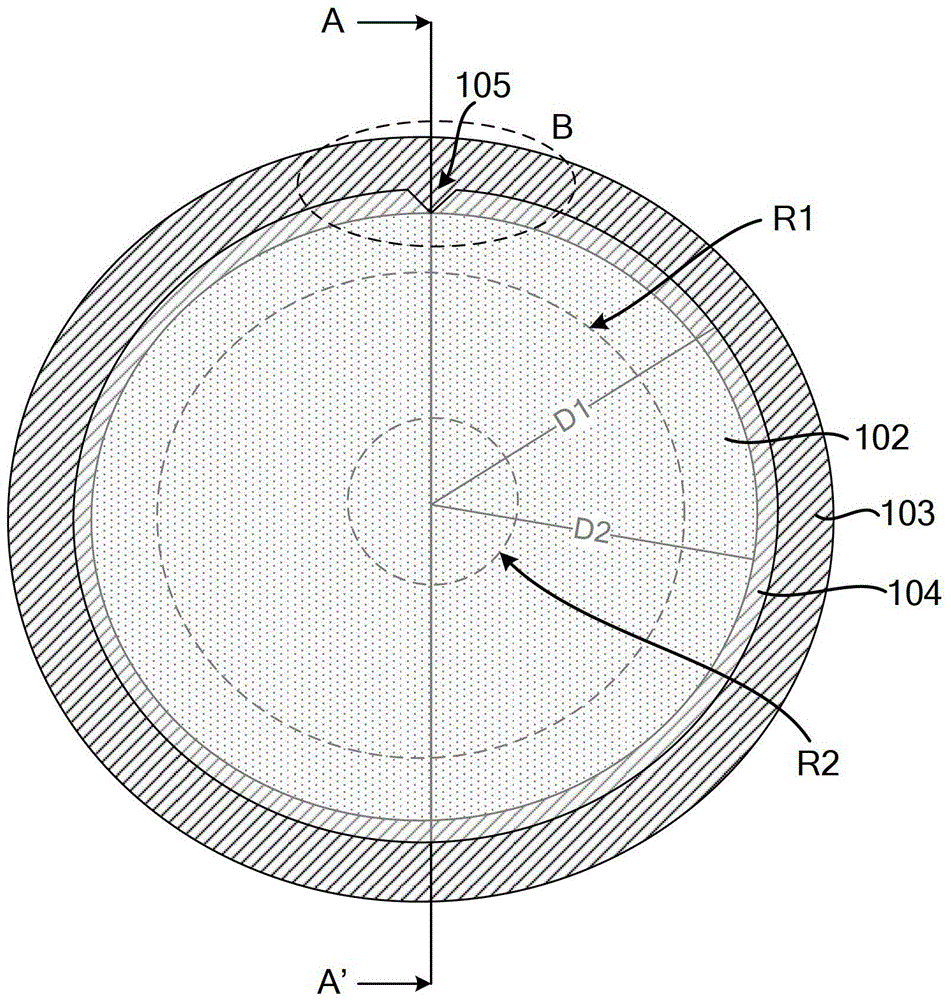

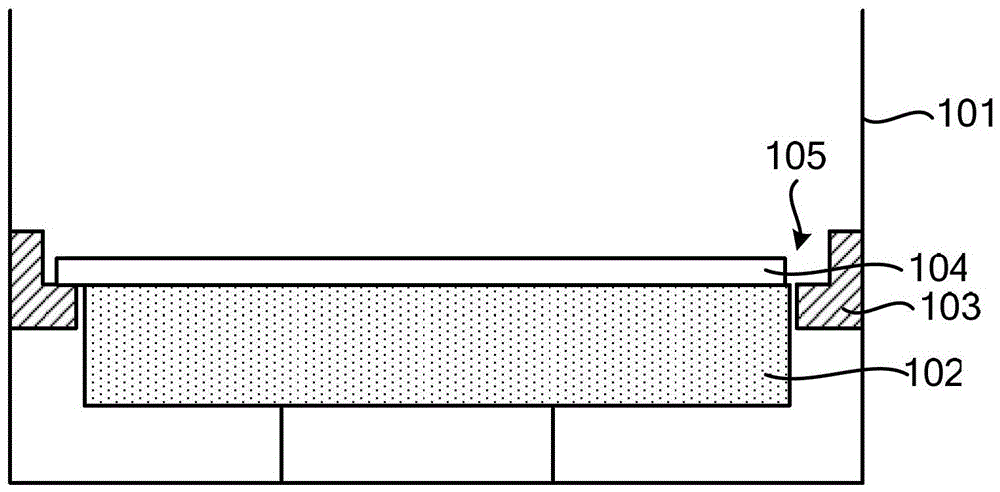

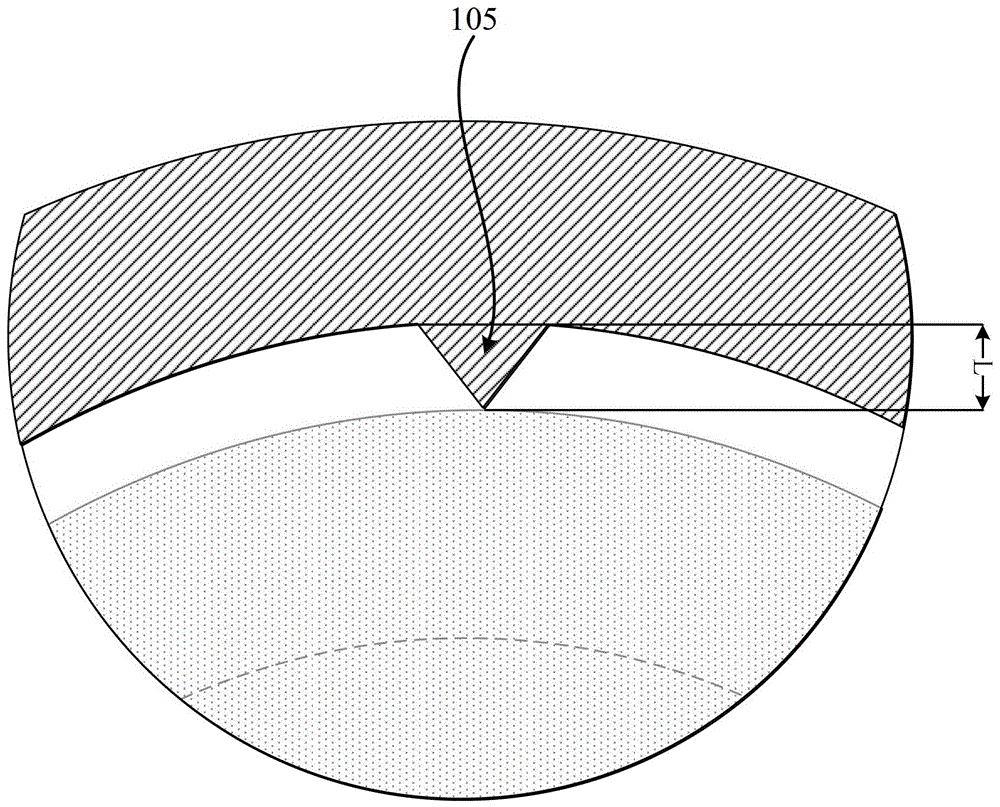

[0037] The core idea of the present invention is to provide a navigation sheet for dry engraving equipment, the navigation sheet is a transparent disc, the diameter of the navigation sheet is less than or equal to the diameter of the inner ring of the bearing ring, and the navigation sheet Scales are provided in multiple radial directions. After the maintenance or repair of the dry engraving equipment is completed, the navigation silicon wafer can be used to determine the transfer position of the manipulator before the silicon wafer is formally produced. When the manipulator placed the navigation sheet on the bearing circle, because the navigation sheet was transparent and also provided with scales in its radial direction, the offset data of the navigation sheet could be read from the scale of the navigation sheet, and the The offset data is fed back to the manipulator to correct the placement position of the subsequent manipulator, and the above steps are repeated until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com