Manufacturing technique of bipolar plate for fuel battery

A manufacturing process and fuel cell technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of fragile, time-consuming, difficult to achieve mixing effects, etc., to achieve the effect of improving performance and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

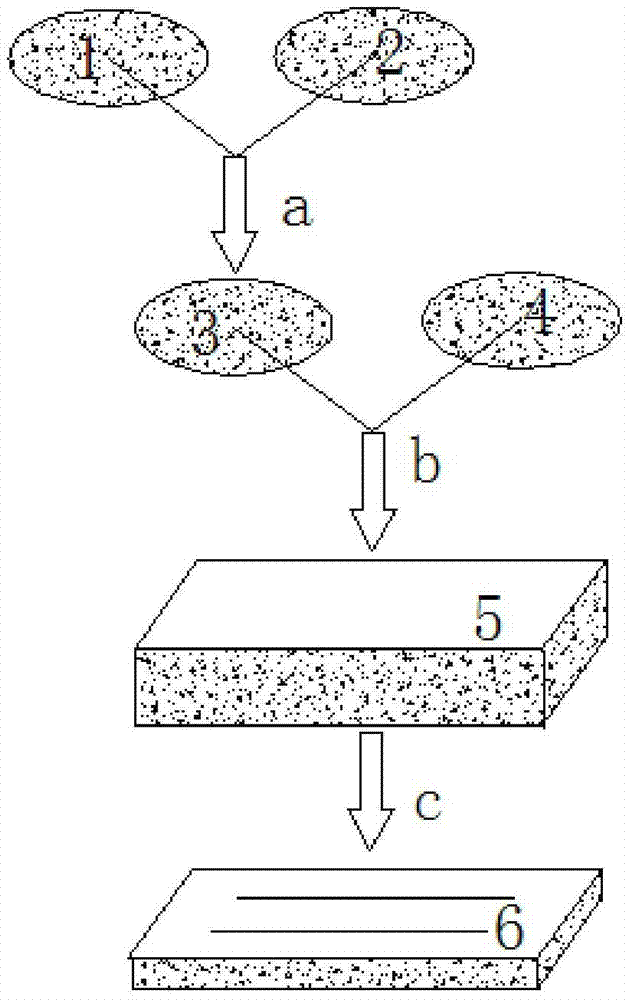

[0037] The present invention will be further described below according to accompanying drawing and specific embodiment:

[0038] 1) Dry-mix the resin powder (70-90wt%) that meets the particle size requirements after grinding and sieving with carbon black / carbon fiber (10-30wt%), and make sure to mix evenly;

[0039] 2) Afterwards, mix the carbon black / carbon fiber resin (30-50wt%) uniformly in an appropriate proportion with the existing expanded graphite (50-70wt%) in proportion; use a mixer to mix and mix for 10-30 minutes, each time The amount of mixing should not be too much, it is mixed according to the amount of a molded bipolar plate;

[0040] 3) Press the mixed expanded graphite, resin, carbon black / carbon fiber mixture into a pre-pressed plate with a certain thickness and shape, the thickness of the pre-pressed plate is 3-7mm, and the density is 0.2-1.0g / cm 3 , When pre-pressing, attention should be paid to the pressing distance and pressing time of the molding machin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com