PC-PBT (polycarbonate-polybutylene terephthalate) hybrid alloy and preparation method thereof

An alloy and polycarbonate technology, applied in the field of flame retardant materials, can solve the problems of poor toughness and solvent resistance, yellowing of mixed alloy color, etc., and achieve the effect of good toughness, solvent resistance and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Preparation of PC and PBT mixed alloy particles

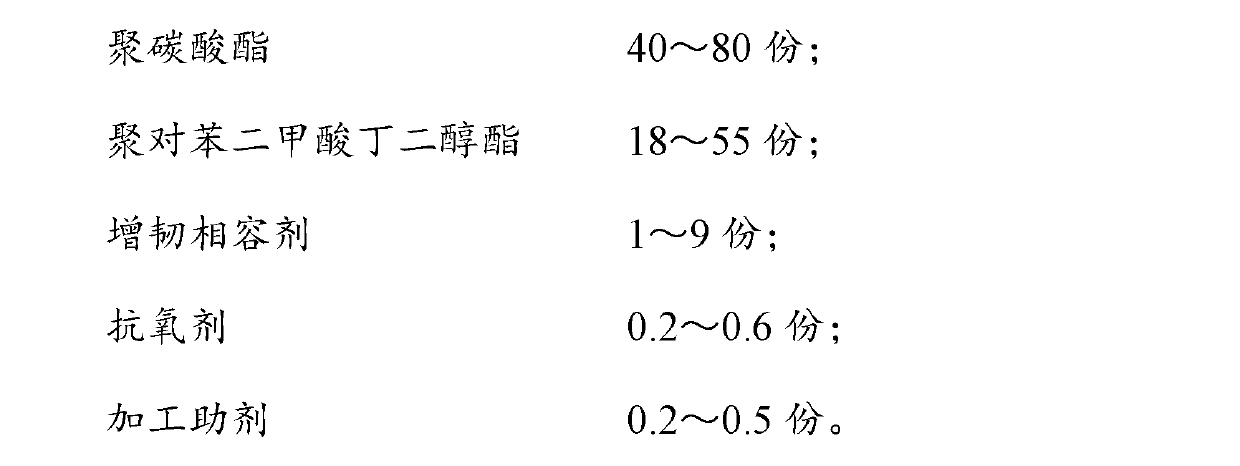

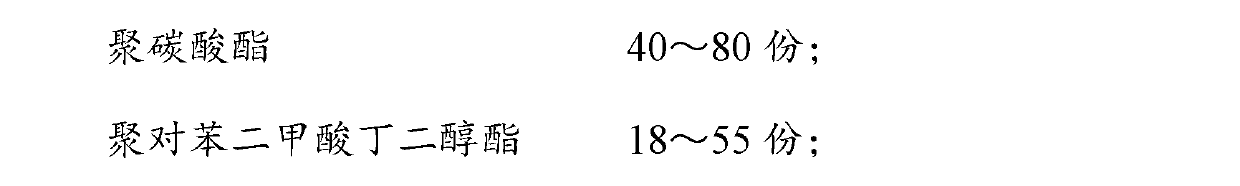

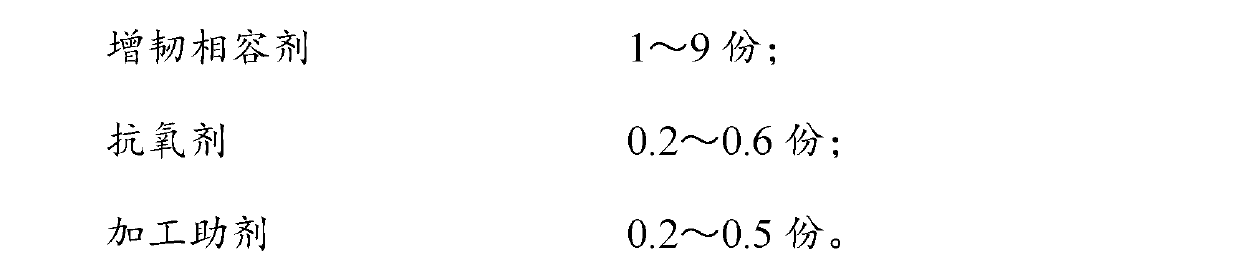

[0027] The mixed alloy is based on 100 parts by mass, and the preparation method comprises the following steps:

[0028] Step 1, according to the contents of each component specified in Table 1, the following components are added: polycarbonate; polybutylene terephthalate; toughening compatibilizer; antioxidant; Stir in a blender for 4-6 minutes to form a uniform mixture;

[0029] Step 2. Add the mixed material into the twin-screw extruder, control the temperature of each heating zone of the extruder barrel and die head between 230-260°C, and the mixed material at 230-260°C Melting and kneading and extruding under the condition of ℃, cooling under normal temperature and pressure after extrusion to obtain PC and PBT mixed alloy.

[0030] Wherein, after the PC, PBT mixed alloy is melted, kneaded and extruded from the extruder, the PC, PBT mixed alloy particles are obtained by performing stranding, cooling, drying and ...

Embodiment 2

[0034] The method of Example 1 was repeated according to the content of each component specified in Table 1, and the properties of the PC and PBT mixed alloy particles prepared in this example were measured according to the standards described in Table 1. See Table 1 for the measurement results.

Embodiment 3

[0038] The method of Example 1 was repeated according to the content of each component specified in Table 1, and the properties of the PC and PBT mixed alloy particles prepared in this example were measured according to the standards described in Table 1. See Table 1 for the measurement results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com