Multi-parameter real-time monitoring system for post-segment grouting of shield tunnel segment wall

A shield tunnel segment and synchronous grouting technology, which is applied in the quality control of the synchronous grouting construction process behind the shield tunnel segment wall, and in the field of multi-parameter real-time monitoring, can solve grouting dissatisfaction, segment cracking, large slurry, etc. To solve the problem, achieve the effect of flexible and convenient layout and reduce on-site wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation process of the technical solution of the present invention will be described below in conjunction with a specific example, and the present invention will be further described in detail, but the application of the present invention is not limited thereto.

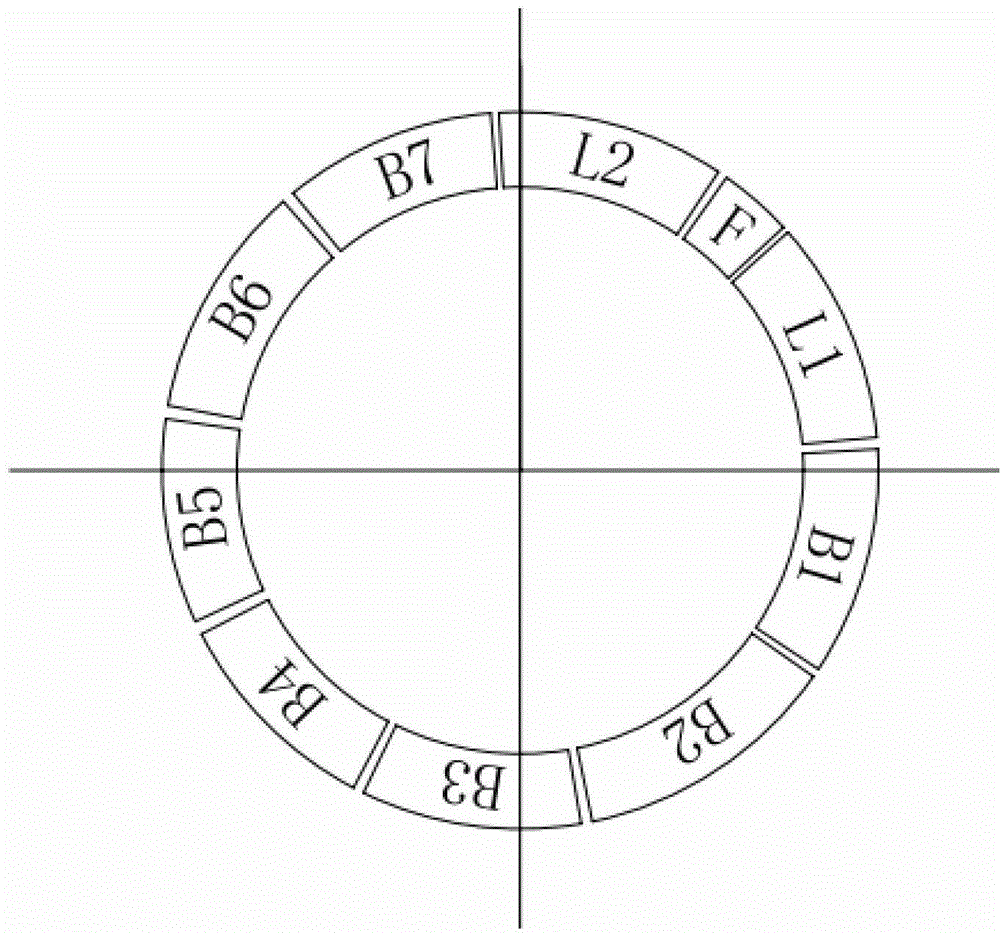

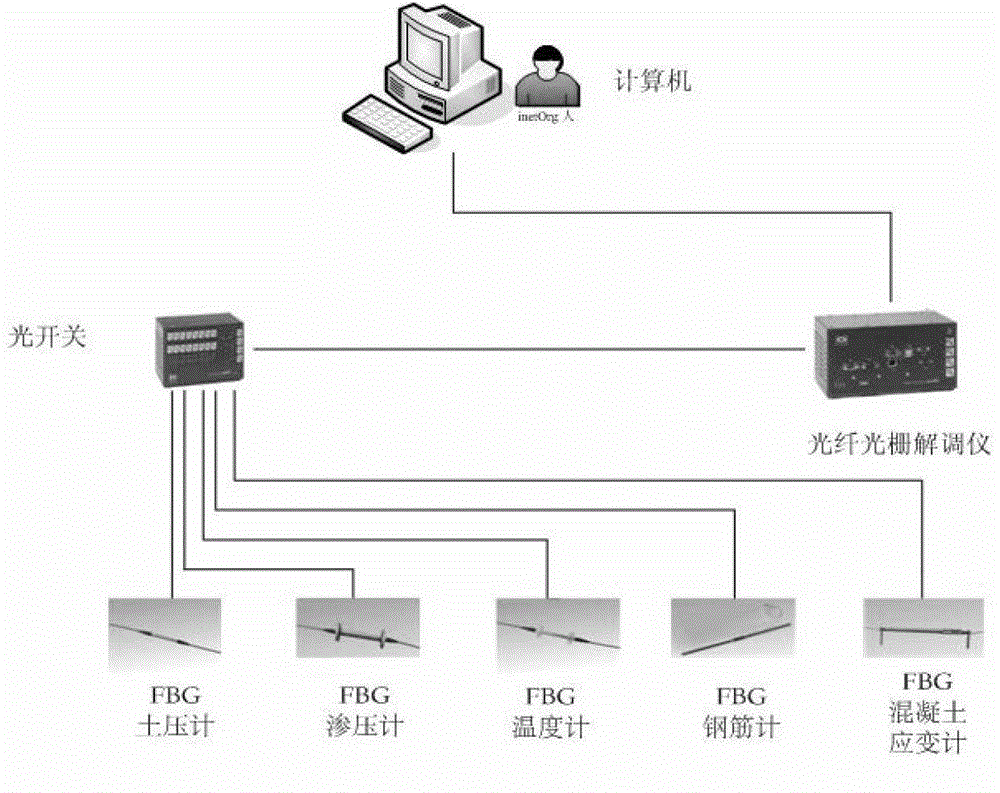

[0024] The present invention is a multi-parameter real-time monitoring method and system for synchronous grouting behind the segment wall of a shield tunnel based on fiber grating sensing and optical fiber communication. The specific implementation includes the following implementation steps:

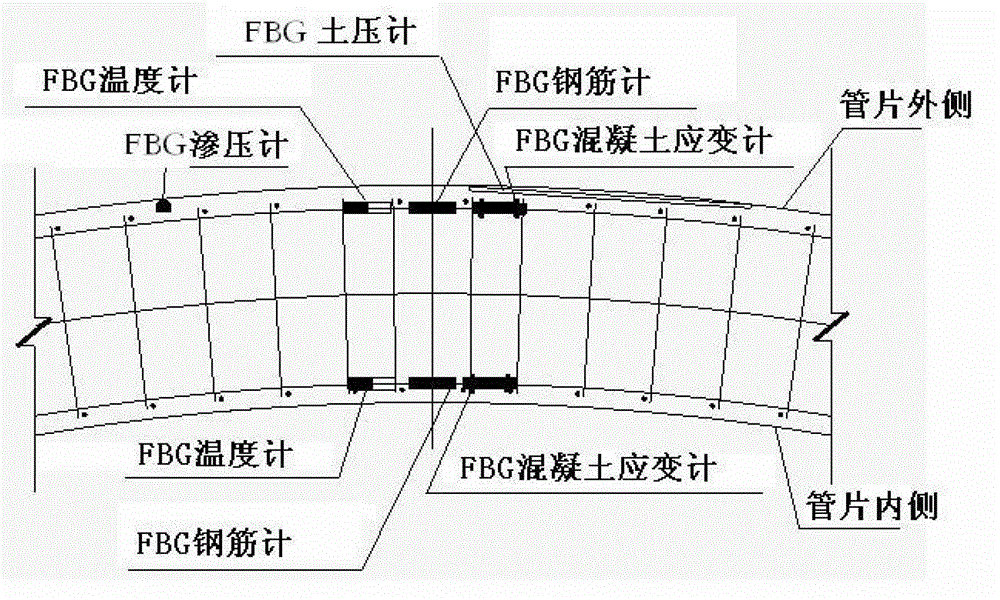

[0025] 1) Install the fiber grating sensors such as thermometers, concrete strain gauges, steel bar gauges, soil pressure gauges, osmometers, etc. on the control points of the segments before concrete pouring of the prefabricated segments, and pre-embed various sensors in the segments after pouring concrete and curing Inside.

[0026] 2) After the segment is installed in place, lead out the pigtail f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com