Pressing device of positive electrode prefabricated sulfur for sodium-sulfur battery

A sodium-sulfur battery and cathode technology, applied in the field of pressing equipment, can solve the problems of cumbersome process, unfavorable industrialization and large-scale production of sodium-sulfur battery, long production cycle, etc., and achieve the effects of improving the environment, increasing the production efficiency and reducing the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

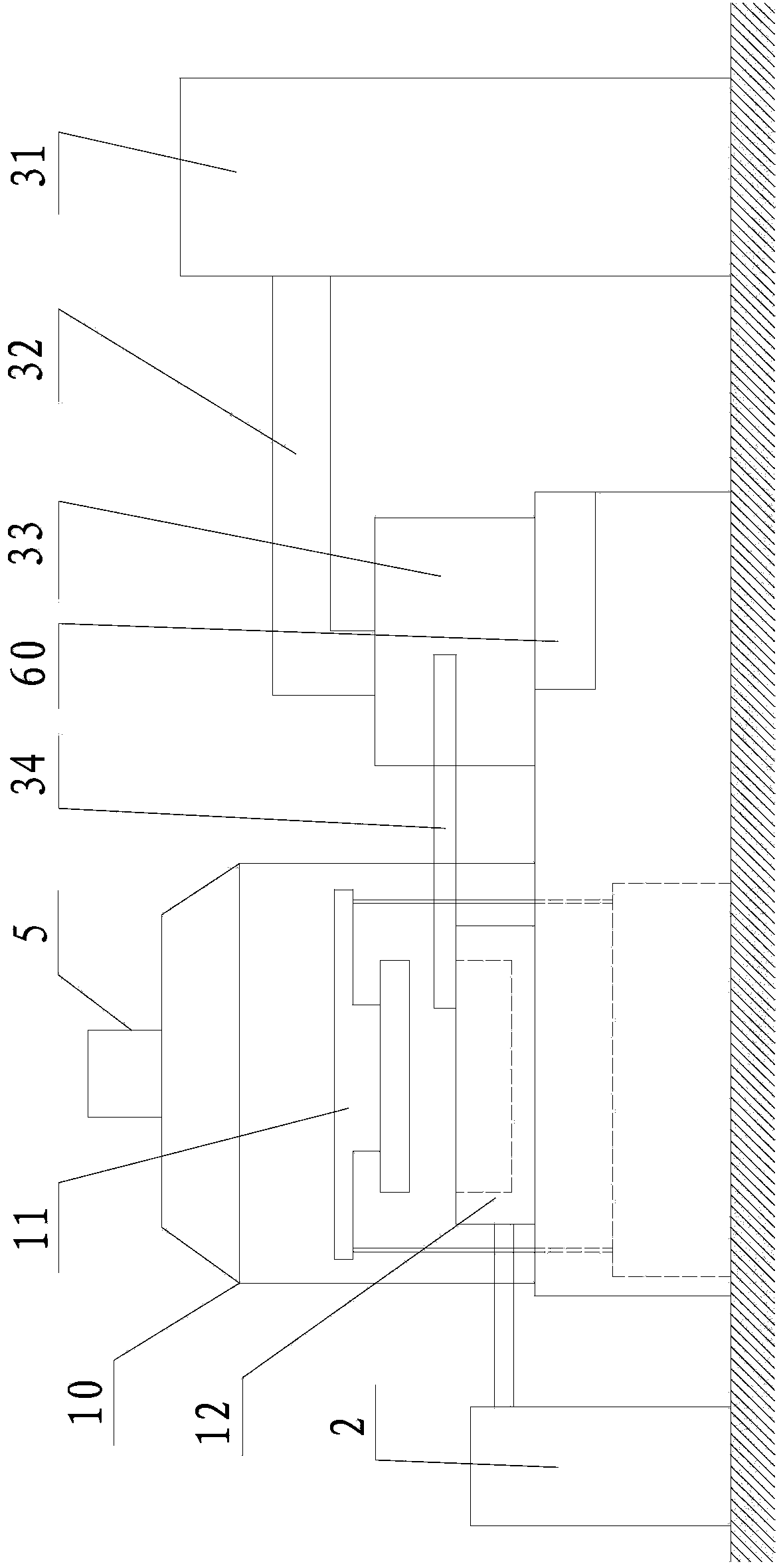

[0012] In order to better understand the technical solution of the present invention, the following will be described in detail through specific embodiments in conjunction with the accompanying drawings:

[0013] see figure 1 , the pressing equipment for the positive electrode prefabricated sulfur of the sodium-sulfur battery of the present invention includes a pressing system, a cooling system 2, a sulfur injection system, a heating system, an exhaust gas discharge system 5 and a control system, wherein,

[0014] The pressing system comprises a pressing chamber 1 and a pressing mold installed in the pressing chamber 10; the pressing mold comprises an upper mold 11 and a lower mold 12, and the upper mold 11 is connected with a press, which is installed on the bottom of the pressing chamber 10 and connected with The hydraulic mechanism 13 driven by the signal connection of the control system,

[0015] The cooling system 2 is a gradient cooling system, and the cooling system 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com