Intermittent reaction constant dosing chlorine dioxide preparation device and method

A chlorine dioxide and preparation device technology, applied in the direction of chemical methods for reacting liquids, chlorine oxide, chemical instruments and methods, etc., can solve problems such as difficult control, low concentration of disinfectant, large flow, etc., and achieve on-site installation Simplicity, improved safety, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

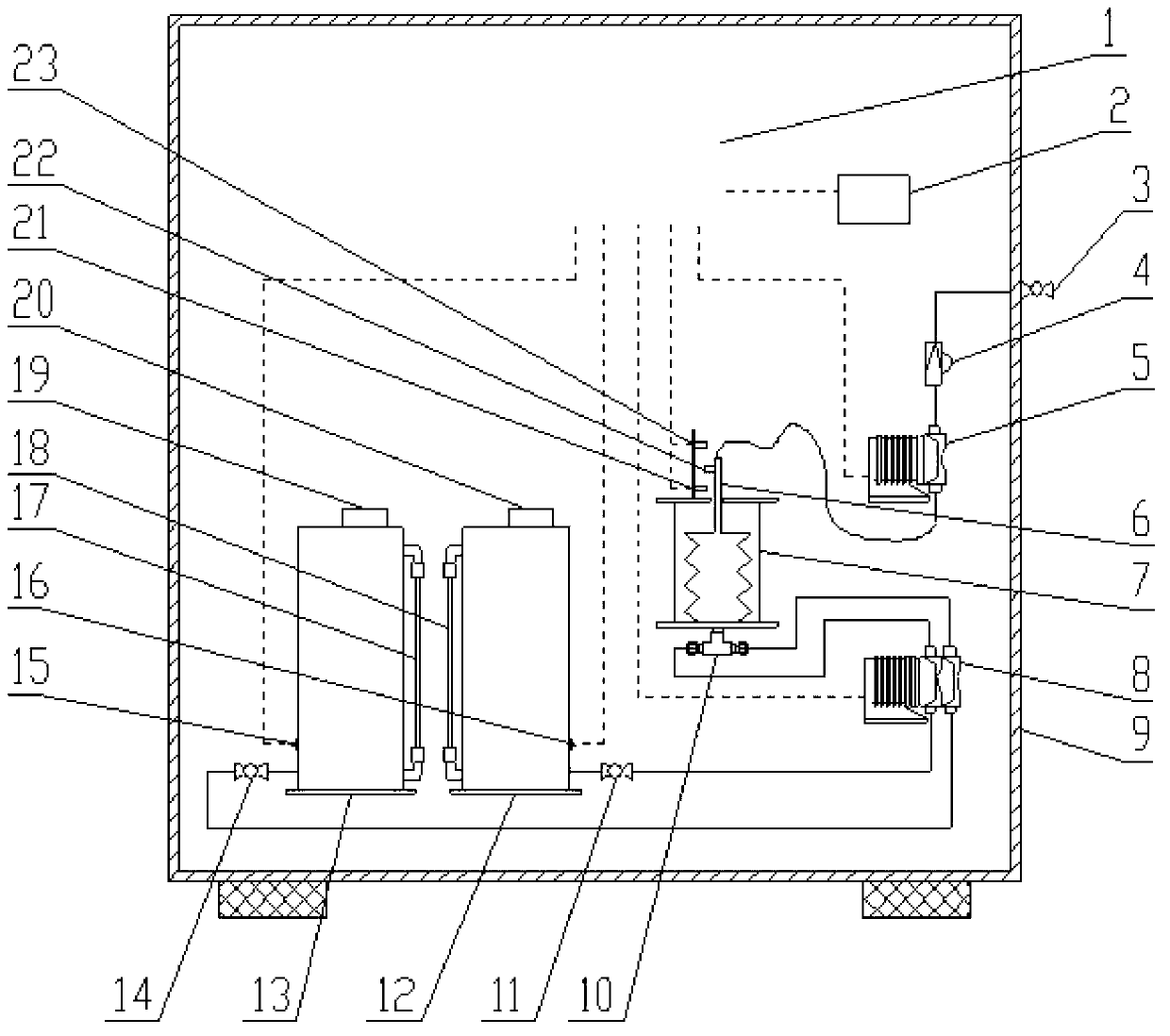

[0031] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0032] A chlorine dioxide preparation device for intermittent reaction and continuous addition, which comprises a shell 9 and a controller 1, and the shell is provided with a hydrochloric acid tank 13, a sodium chlorite tank 12, a raw material feeding metering pump 8, a disinfection Liquid metering pump 5, reactor 7, the hydrochloric acid tank 13, the sodium chlorite tank 12 are respectively connected with the raw material feeding metering pump 8, the reactor 7 is respectively connected with the raw material feeding metering pump 8, the disinfecting liquid metering pump 5, the hydrochloric acid tank The bottom of 13 is provided with a hydrochloric acid low level switch 15, the bottom of the sodium chlorite tank 12 is provided with a sodium chlorite low level switch 16, the reactor 7 is provided with a travel switch, the hydrochloric acid low level switch 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com