Bauxite grinding system equipment and grinding process

A kind of system equipment and bauxite technology, applied in the direction of grain processing, etc., can solve the problems of high energy consumption, low production capacity, coarsening of bauxite particles, etc., achieve low noise, increase production capacity, and reduce the amount of ore entering the grinding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

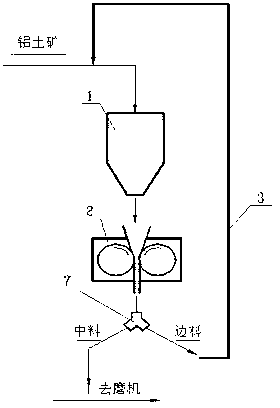

[0020] Embodiment 1: The equipment of the bauxite grinding system is as follows: the high-level feeding bin 1 is connected to the high-pressure roller mill 2, the high-pressure roller mill 2 is connected to the distributor 7, and the edge material outlet of the material distributor 7 is connected to the edge material circulation System 3 is connected. The side material circulation system 3 includes a side material cutting machine and a bucket elevator, and the bucket elevator is connected with the high-level feeding bin 1 .

[0021] The grinding process using bauxite grinding system equipment is (see attached figure 1 . ), after the crushing section and before the raw material grinding section in the traditional pulp preparation system, an ore pre-grinding process with high-pressure roller mill as the main equipment is added. The specific process of the pre-grinding section is as follows: the crushed ore is sent to the high-level feeding bin 1 above the high-pressure roller ...

Embodiment 2

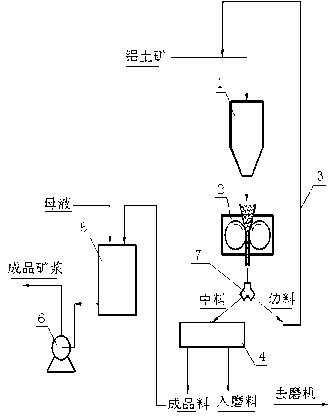

[0022] Embodiment 2: Bauxite grinding system equipment On the basis of Embodiment 1, there is also: the middle material outlet of the distributor 7 is connected with the ore classification system 4, the ore classification system 4 is connected with the finished pulp tank 5, and the finished pulp is The tank 5 is connected with the finished pulp pump 6 .

[0023] The grinding process of the bauxite grinding system equipment is as follows: the crushed ore enters the high-level feeding silo 1 through the bucket elevator, and after a short storage in the silo, the ore enters the high-pressure roller mill 2 evenly for rolling, The rolled "side material" is sent to the hopper elevator through the side material circulation system 3 and then enters the high-pressure roller press 1 for rolling; the rolled "middle material" enters the ore classification system 4 for classification. This system screens out the qualified ore from the raw ore pulp that can be directly prepared in the "inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com