Laminated synthetic stone raw material composition and production method for manufacturing laminated synthetic stone

A technology of raw material composition and production method, which is applied in the field of laminated synthetic stone raw material composition and laminated synthetic stone, can solve the problems that the product performance cannot be fundamentally improved, the temperature resistance level of synthetic stone is lowered, and the operating environment is polluted. Achieve good formability, improved performance, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the implementation manners of the present invention will be further described in detail below.

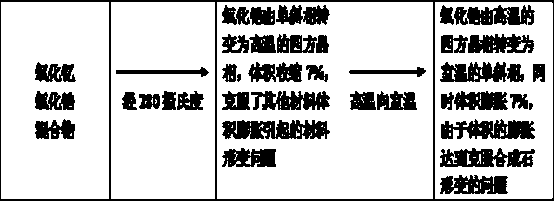

[0017] The invention provides a laminated synthetic stone raw material composition and a production method for producing an improved laminated synthetic stone using the raw material composition. The laminated synthetic stone raw material composition includes epoxy resin, glass felt fiber and yttrium oxide A eutectic formed with zirconia at 280°C, the yttrium oxide is yttrium oxide with a mass fraction of 1%, and the zirconia is zirconia with a mass fraction of 5%.

[0018] The production method of using the raw material composition to produce the improved laminated synthetic stone comprises the following steps:

[0019] (1) Make epoxy resin and glass felt fibers into composite materials;

[0020] (2) Take the composite material in step (1) and place it in the prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com